2

Model 710DU Trip/Calibration System

•Qualified per IEEE Std 323-1974 and

IEEE Std 344-1975

•Use with 4–20 transmitters or 3-wire

100 Vplatinum RTD’s

•Exceptional reliable modular design

•Up to 8 precision trip points per signal

FEATURES

Rosemount® Model 710DU Trip/Calibration

Systems continuously monitor critical process

parameters and provide highly accurate alarm

action. As many as eight precision-calibrated trip

points can be assigned to a single sensor channel.

Any trip point can be quickly verified or changed.

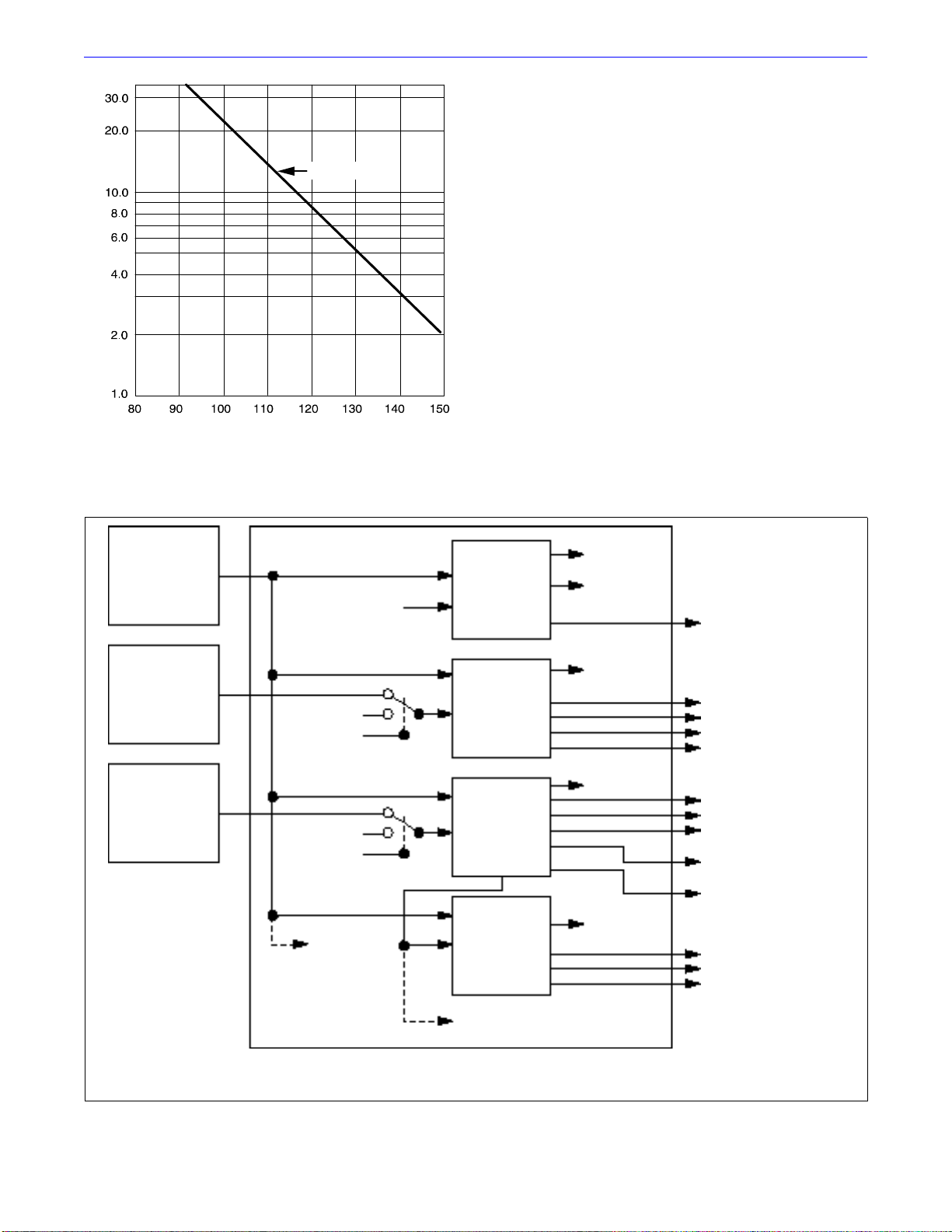

The system consists of a card file with a plug-in

calibration unit and space for up to 12 interchangeable

trip unit modules. These features make Model 710DU

Systems highly flexible, simple to install or reconfigure,

and easy to calibrate.

OPERATION

Trip Unit

One master trip unit is required for each 4–20 mA

transmitter or RTD input. A basic master trip unit

displays the sensor output, provides one high or low

trip circuit, a high/low gross failure circuit, and a

proportional analog output for driving up to seven

slave trip units.

Each slave adds one additional trip point and gross

failure circuit to the transmitter loop. The trip

output of any master or slave trip unit can drive an

external relay. The auxiliary analog output of the

master trip unit can be used to drive an external

proportional controller or recorder.

The trip point circuit features precision external

adjustment with either high or low nonlatching trip

action. The gross failure circuits are internally

adjustable with manual reset high and low trip

action. Trip point and gross failure indicating lamps

are furnished on each trip unit.

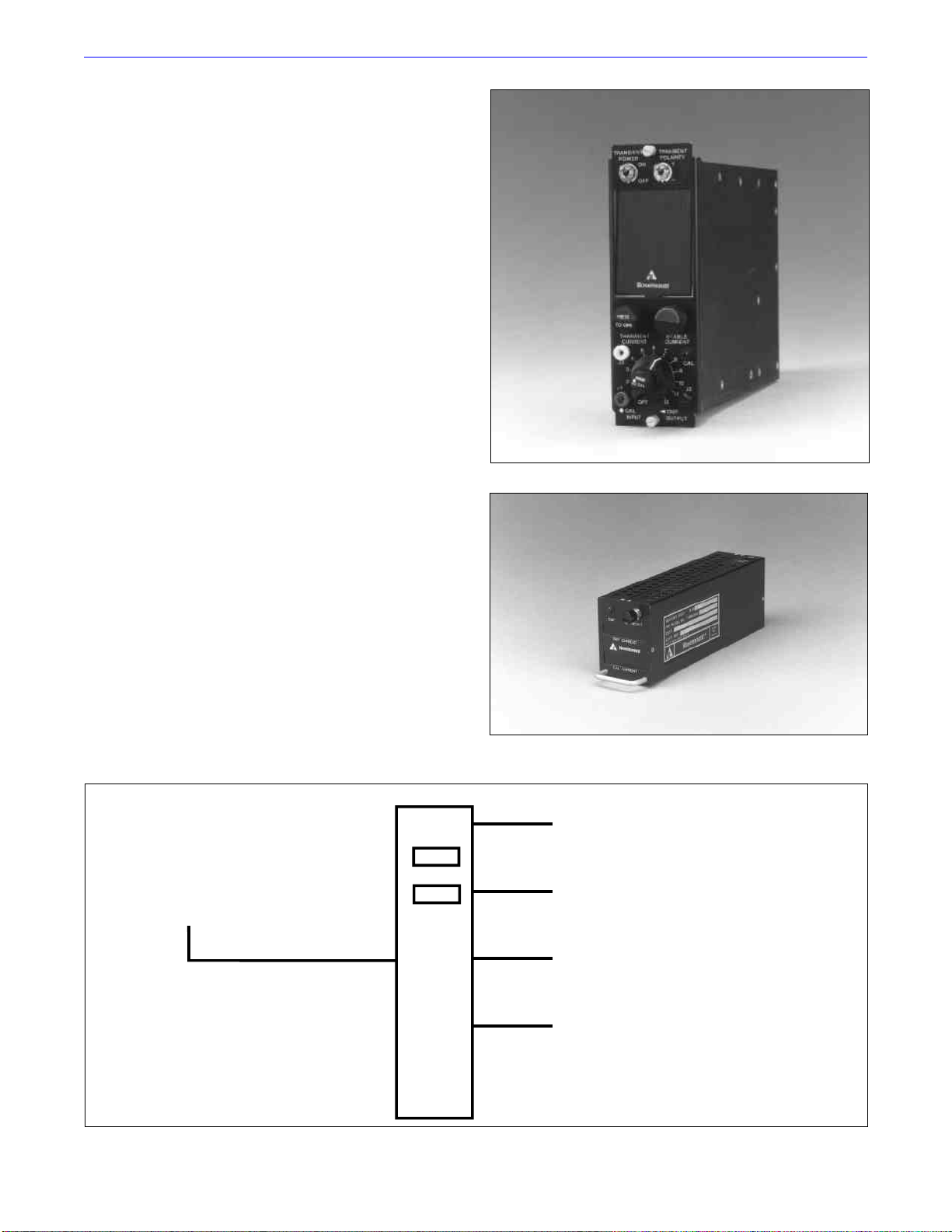

Calibration Unit

The trip point for any master or slave trip unit

within the card file can be read or accurately

calibrated by the calibration unit. This unit provides

space for a unique digital readout assembly and

permits the operator to automatically replace the

field transmitter input signal to any channel with a

precisely adjustable calibration signal. This enables

the trip point to be compared exactly with the

desired input signal level. After the trip points for all

channels within the file have been set, the readout

assembly can be removed and plugged into any other

calibration unit.

Applications

Model 710DU trip/calibration systems are ideally

suited to nuclear power applications or any process

where frequent calibrations of trip points are

essential. Critical process trip points are repeatable

within 0.13% of span for 4–20 mA transmitter inputs

and 0.75% of span for RTD inputs under normal

conditions. System components have been qualified

per IEEE Std 323-1974 and IEEE Std 344-1975 as

stated in Rosemount Qualification Reports

D8200037 and D8300112.

Rosemount and the Rosemount logotype are registered trademarks of

Rosemount Inc.

Cover Photo: 710-001AB