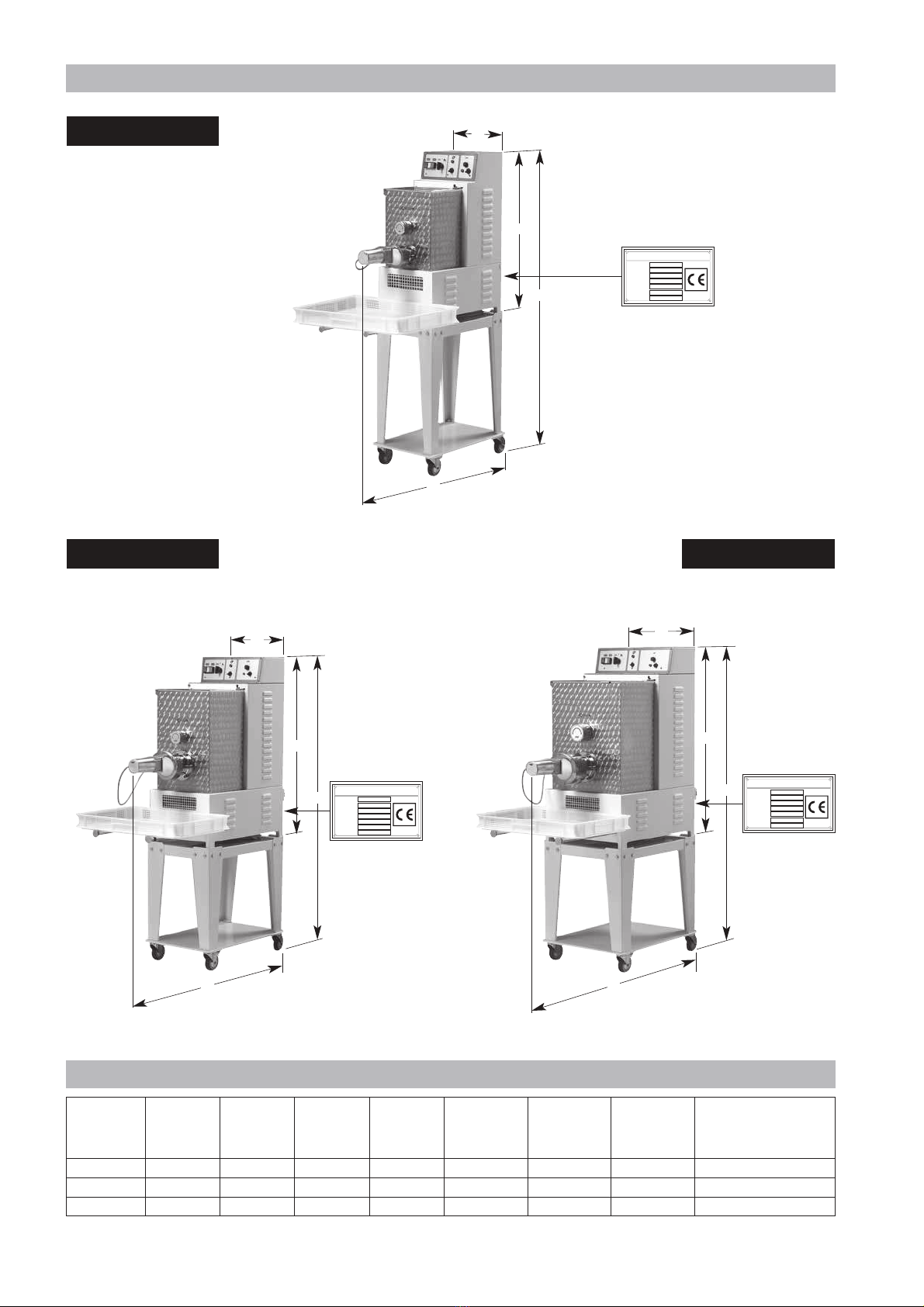

Model 3-phase standard power 1-phase optional power

230 50-60 Hz. 400 50-60 Hz. 415 50-60 Hz. 110 60 Hz. 230 50-60 Hz. 240 50 Hz.

TR 75/C YES YES YES YES YES YES

TR 95 YES YES YES /YES YES

TR 110 YES YES YES /YES YES

TRD 110 YES YES YES ///

TR 110 S YES YES YES ///

TRD 110 S YES YES YES ///

32

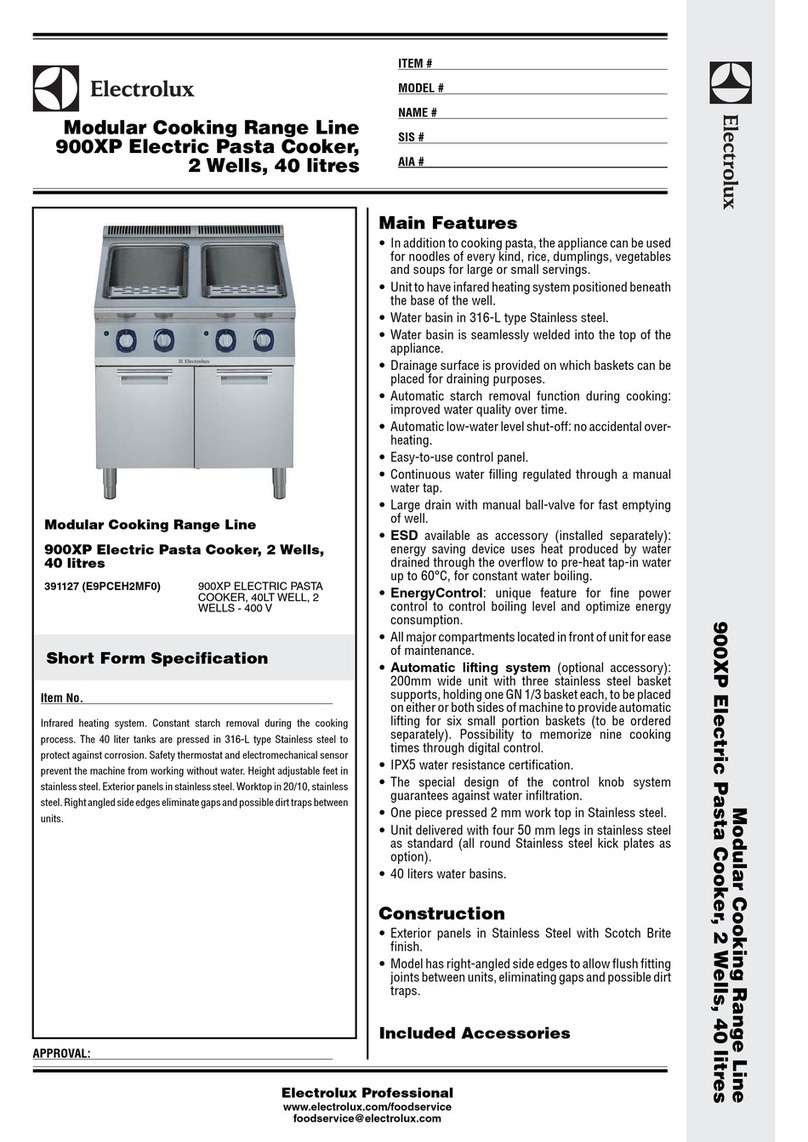

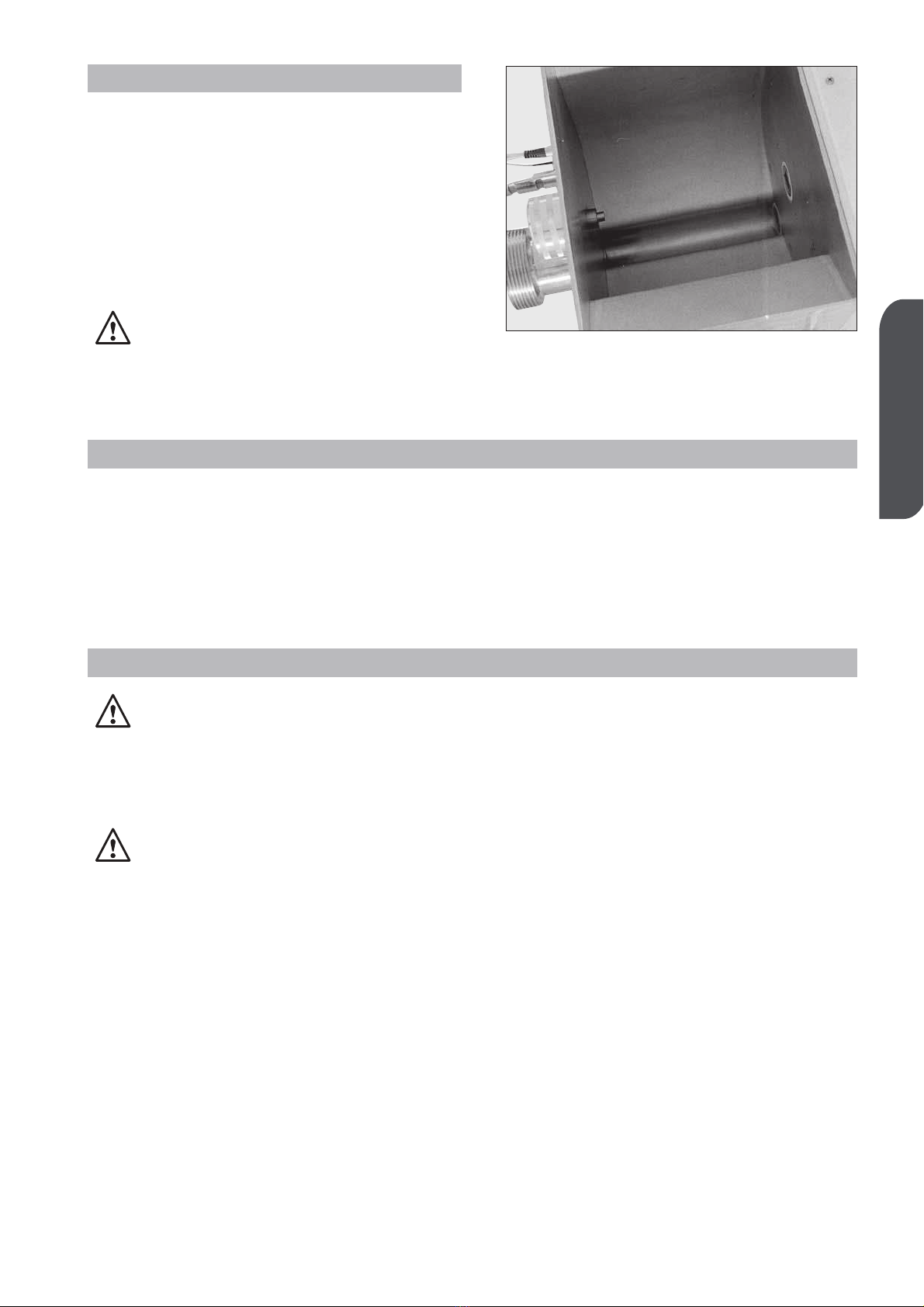

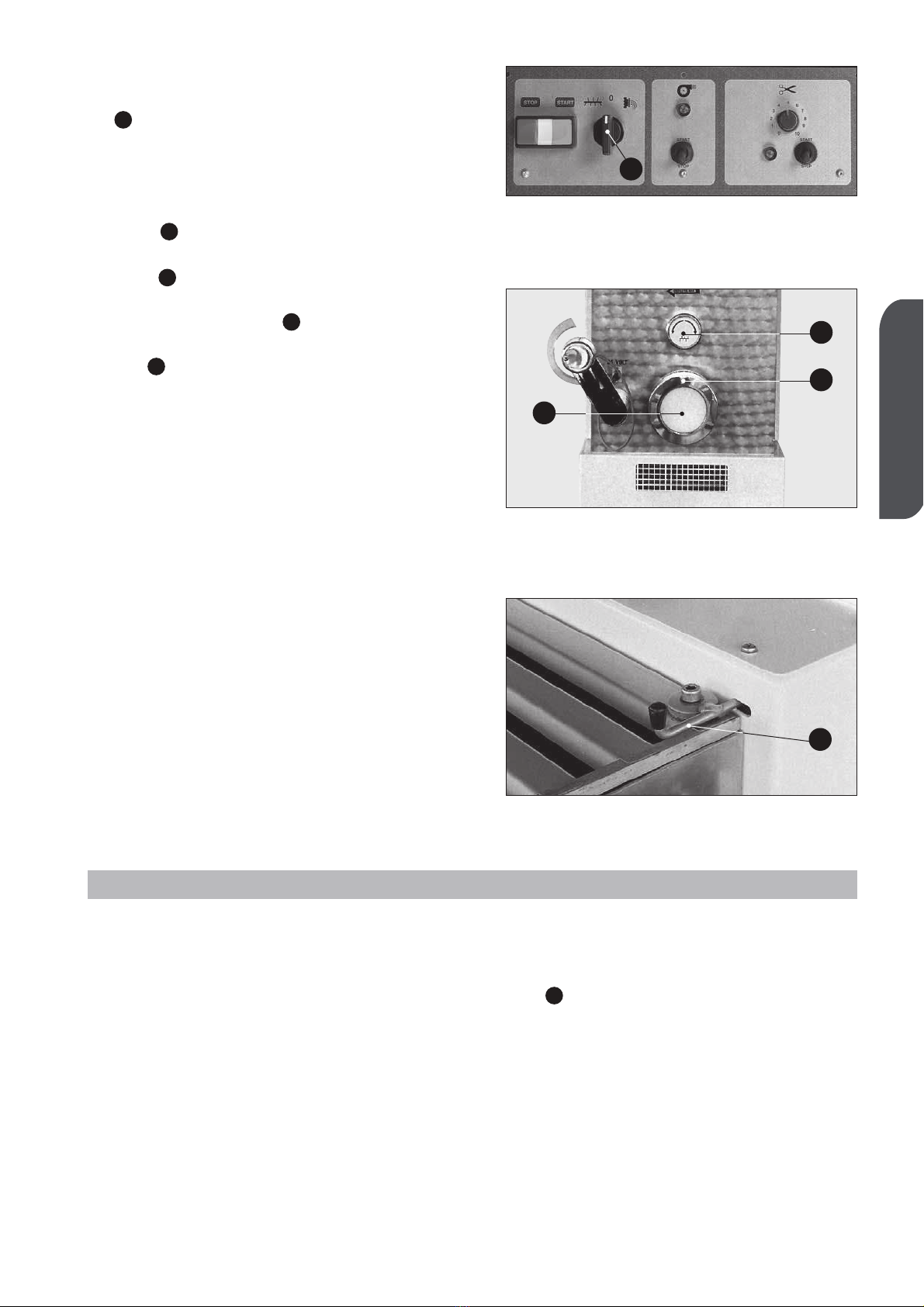

• The elements in contact with the noodles

are made of stainless steel or bronze for

foodstuffs.

• Moving parts mounted on ball bearings

with long-life sealing gaskets or with sup-

ports with greaser.

• Motor-powered; belt transmissions with

maintenance-free reduction gear and

mixer chain.

• Machine fitted with support toes with ela-

stic caps and, on request, trolley with four

wheels, 2 of which fitted with a brake and

machine corner retaining rims.

• Connection by flameproof power cable

according to the supply voltage required,

standard length L = 3 m, without terminal

plug.

• Accessories supplied:

- pasta-collecting frame

- metal ring blocking key

- liquid measuring jar.

• Pasta cutting unit, fitted with a low voltage

operated motor and cutter.

• Fan for drying the pasta surface, to pre-

vent product from sticking.

• Working elements with the ability of turning

in two directions: this enables the knea-

ding of the initial dough, not yet ready,

without any damage to the drawing group.

• Iron parts are protected with stove-ena-

melled epoxy coating.

• Easy disassembling of the working parts;

the machine is freely accessible in order to

carry out thorough cleaning.

• The possibility of obtaining different pro-

ducts thanks to the change of the relevant

drawplate.

• Cooling unit with extrusion sleeve to ensu-

re an ideal temperature and control of

parts in contact with the product, from

model TR 95 to model TRD 110 S, on

request only on model TR 75.

• Mod. TRD 110 and TRD 110 S: Machine

with twin dough preparation tank for conti-

nuous production. Independent controls

and inspection of the second tank.

N DLES PR DUCING MACHINE

Produces different kinds of noodles and is basically made up of a

kneading part and an extrusion unit in order to cut the finished product

INSTRUCTIONS

The machine has been foreseen only for the preparation of cereal-based flour noodles

for noodle shops and catering facilities.

WARNING

For reasons of hygiene, health and warranty, it is strictly prohibited to use the

machine for the processing of substances other than foodstuffs. Any other uses

are contrary to the applications, as originally intended by the manufacturer, who shall

as a consequence, not be held liable for any damage to the machine itself or to other

objects, or for any injuries to persons that may arise thereof. In taking the risk of misu-

se, the user will be held responsible for any consequences.

Always keep children away from the machinery.

• Power: