Ros Roca S.A. (The Company) reserves the right to

change the specification, design, material, procedure,

and dimensions of the equipment described herein

without prior notice at any time in the future, in

accordance with the Company’s constant product

improvement policy.

Ros Roca S.A. has made every reasonable effort to

ensure the accuracy of the Company publications,

but nothing shown, described or referred to in the

publications should be regarded as an infallible guide

to the procedures, materials, specification, design

of availability of any particular vehicle, nor does this

publication constitute an offer for sale of any particular

vehicle. No liability can be accepted by the company

for any mechanical or electrical malfunction, damage,

loss injury or death caused by the use of incorrect

or misrepresented information, omissions or errors

that may have arisen during the preparation of this

publication.

© 2015 Ros Roca S.A.

ALL RIGHTS RESERVED.

Compiled and Published by:

ROS ROCA S.A.

Avda. Cervera

Tàrrega

España

Teléfono: +(34) 973 50 81 00

www.rosroca.com

No part of this publication may be reproduced, stored

in a retrieval system or transmitted in any form without

the prior permission of the Company.

Publication Record

Edition Publication reference Publication date Comments

This edition OM1R-SM-GB01R June 2015 First edition.

Original instructions.

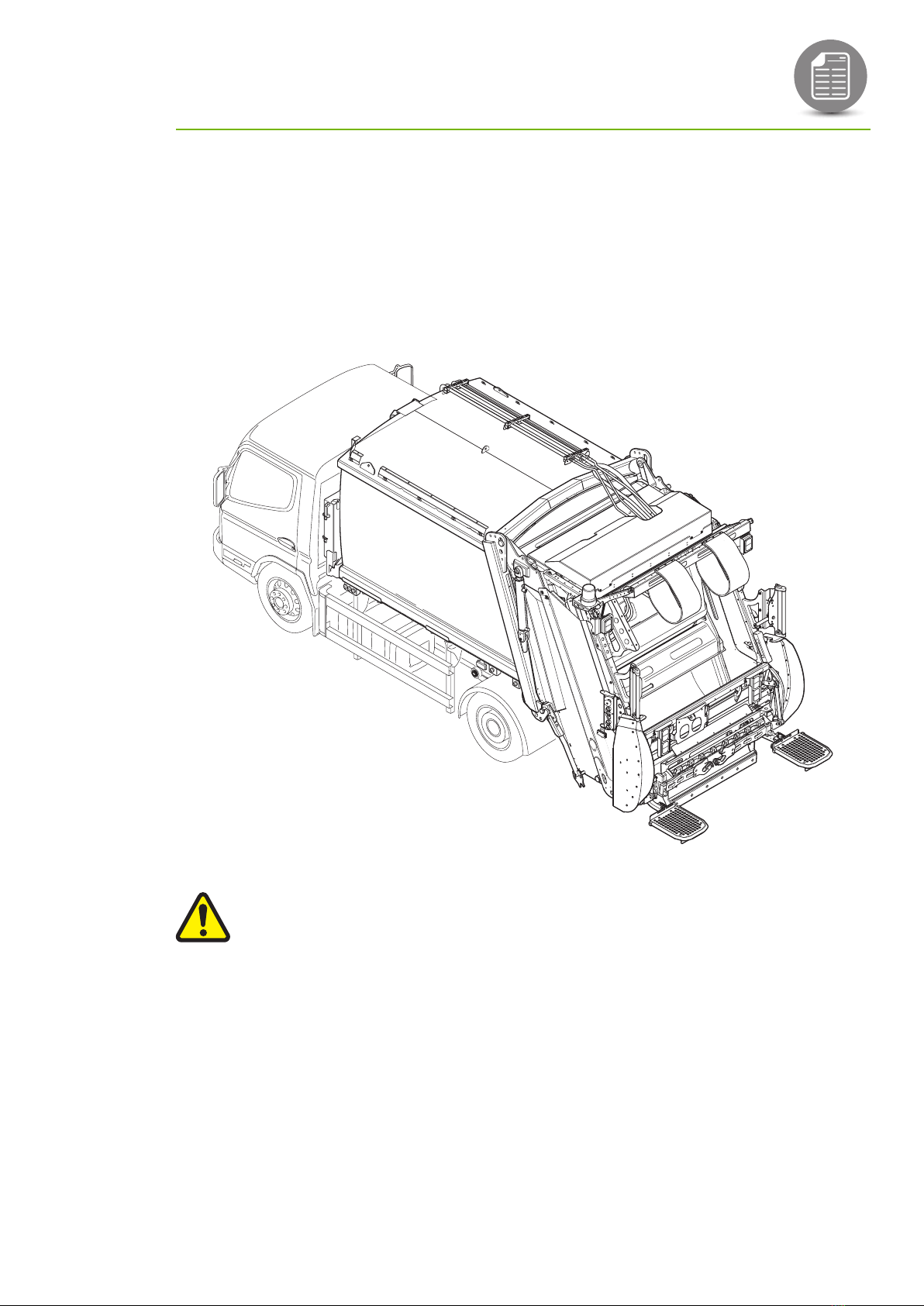

Description

The Olympus Mini refuse collection bodywork is a rear

loaded, fixed refuse collection bodywork manufactured

to EN 1501‑1.

Intended use

The Olympus Mini refuse collection bodywork shall

be mounted on chassis‑cabs specified for refuse

collection application and shall be used to collect and

transport domestic and industrial waste and recyclable

materials.

The Olympus Mini refuse collection bodywork is not

designed for:

• operation in severe conditions, e.g. extreme

environmental conditions such as:

• below – 25 °C and above + 40 °C temperatures;

• operation in a tropical environment;

• operation in wind velocity in excess of 75 km/h;

• operation in a contaminating environment;

• operation in a corrosive environment;

• operation in potentially explosive atmospheres;

• handling of loads the nature of which could lead

to dangerous situations (e.g. hot wastes, acids and

bases, radioactive materials, contaminated waste,

especially fragile loads, explosives);

• operation on ships.

Manufacturer’s name and address

ROS ROCA S.A.

Avda. Cervera

Tàrrega

España

FOREWORD

ii OM1R-SM-GB01R