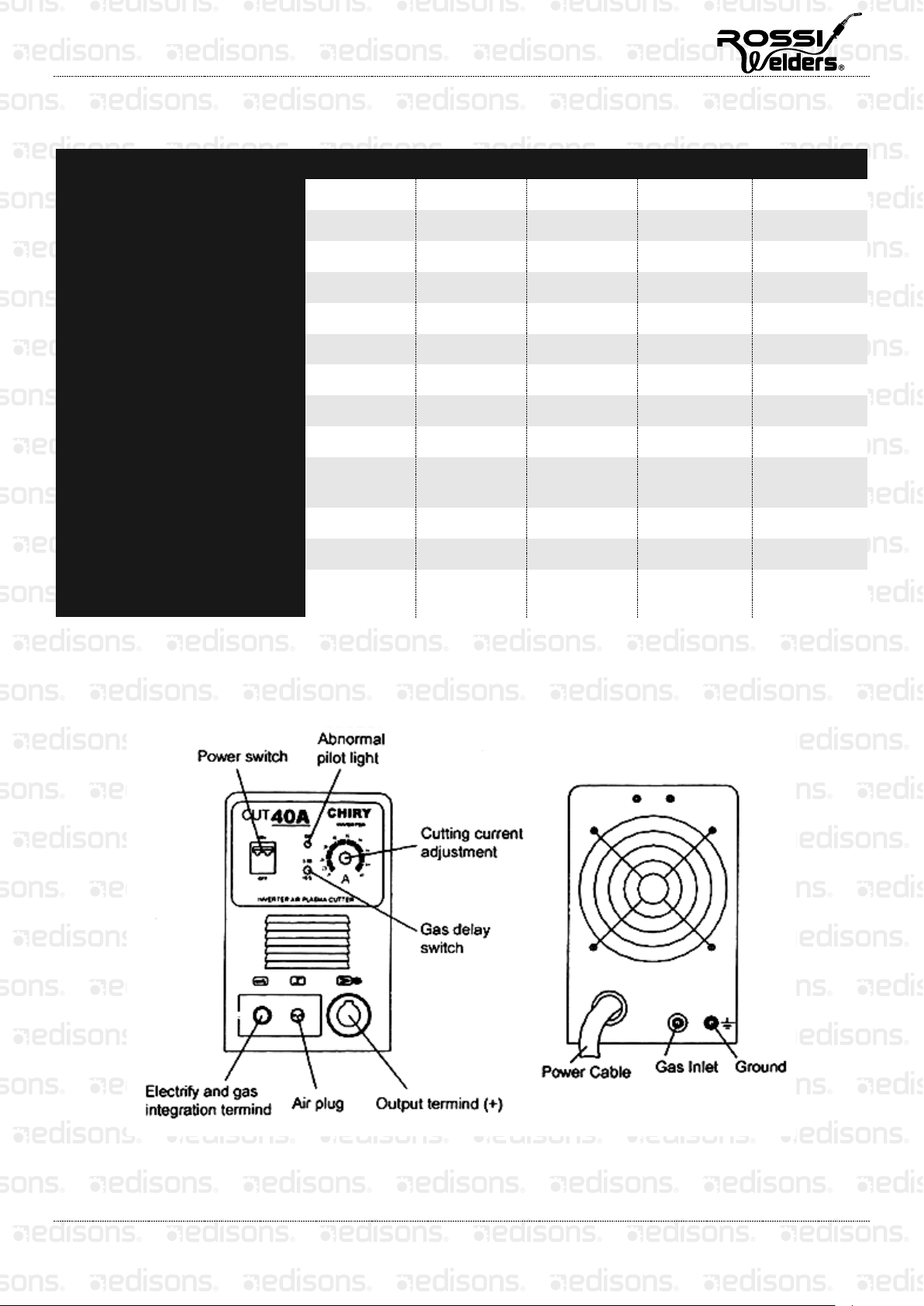

Inverter Welder - Cut 40 Cutter Machine

7

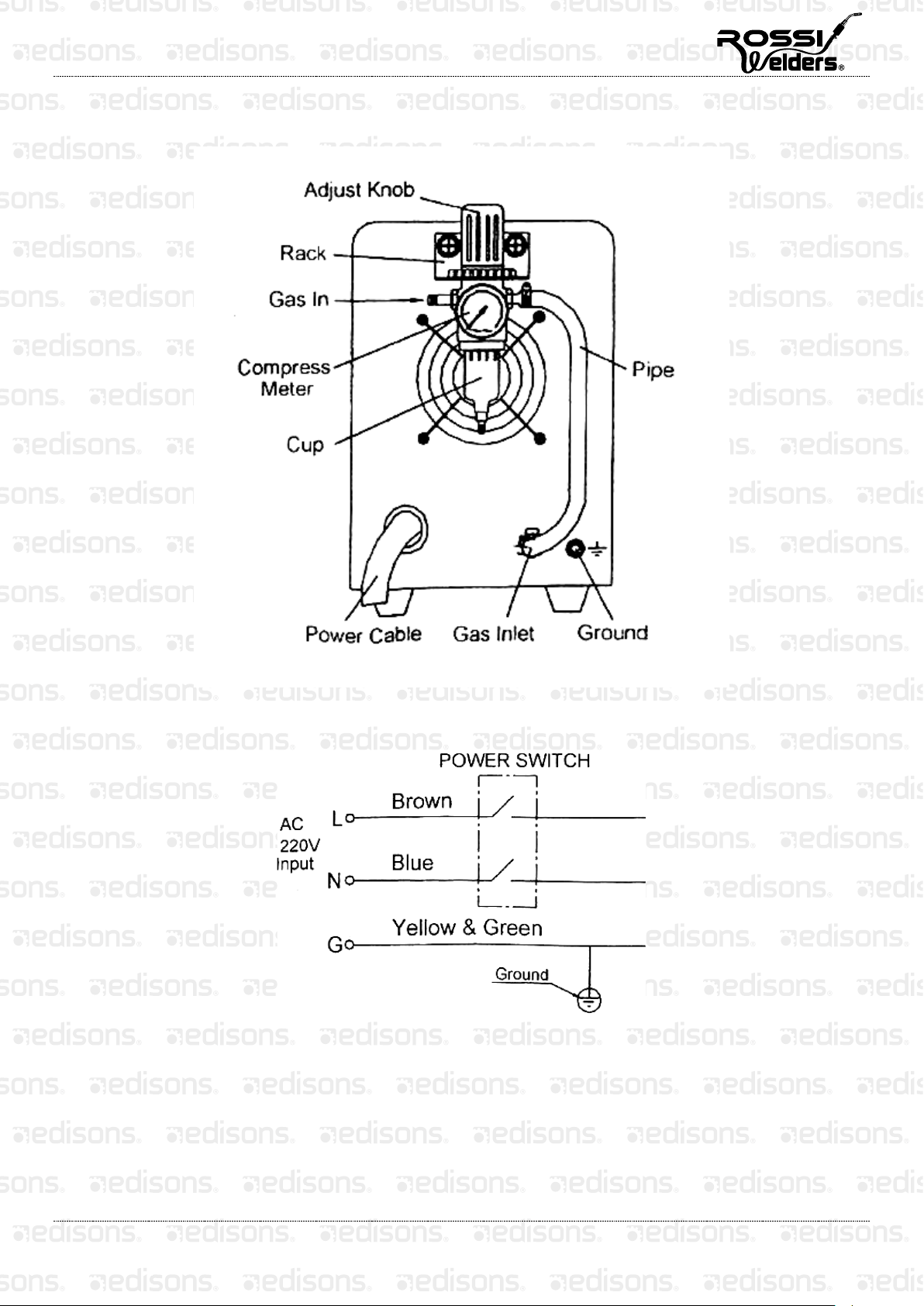

Maintenance

Remove dust and/or dirt with compressed air regularly. If the Inverter Plasma Cutter is placed in an

environment where the condition is filled with smoke and/or dust, the Inverter Plasma Cutter must be

cleaned of dust/dirt every day.

Adequate pressure is set for cutting in order to protect the little components in the machine.

Check the electrical connectors and make sure that the connectors are connected firmly (especially when

connecting and inserting components). If not, tighten the connectors.

Avoid contact with water or other liquids. If the machine has been exposed to wetness/dampness, it must be

dried immediately and measure the insulation by meters. After ascertaining that there are no problems, the

machine can then be operated again.

If the Inverter Plasma Cutter will not be used for a long time, it should be put in its own packing box and

stored in a dry environment.

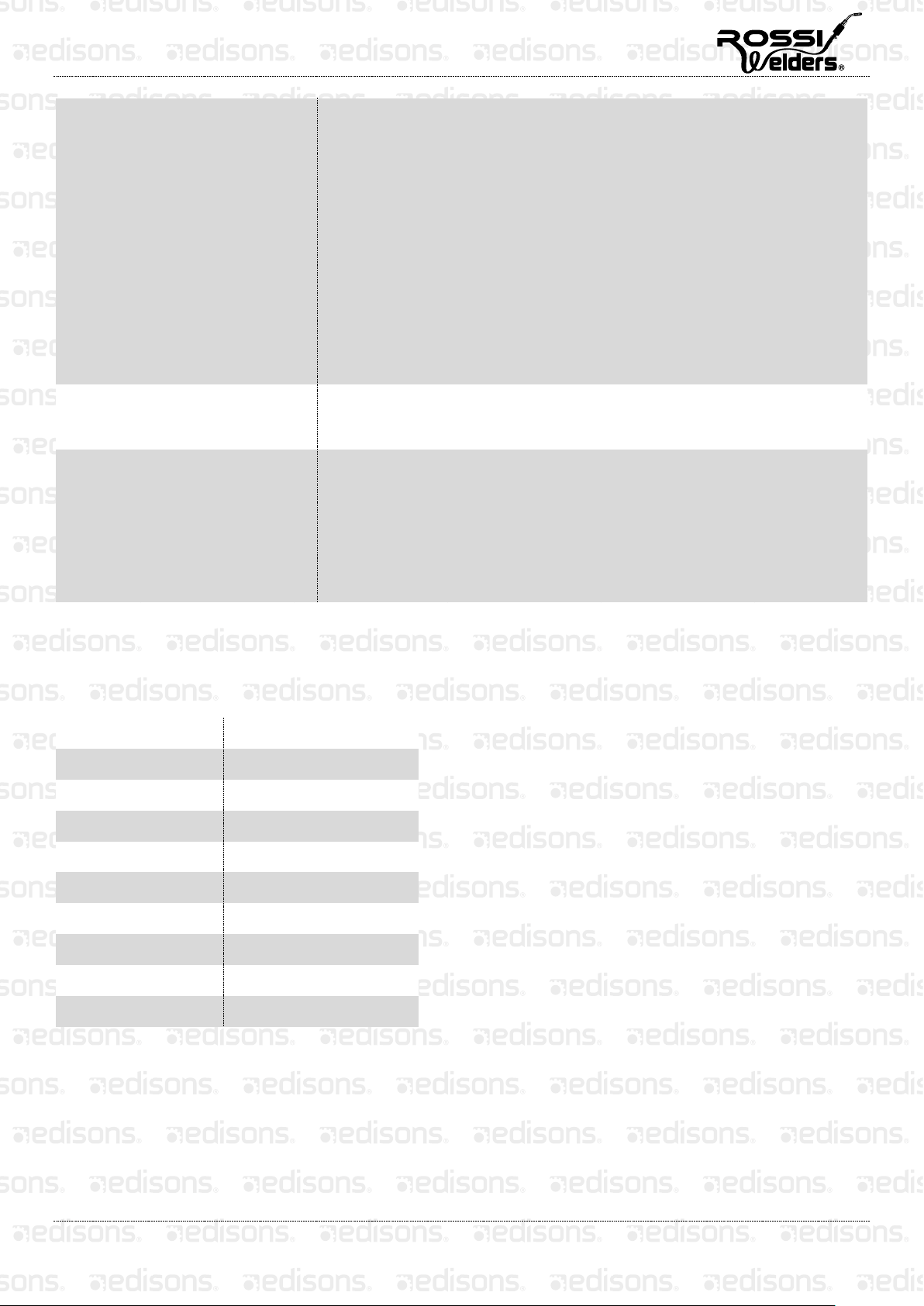

Troubleshooting

Faults Solutions

The power pilot light isn’t on, and the

fan isn’t working; no cutting voltage

output

The power switch is broken.

Check whether the electric net connected to the input wire has electricity.

Check whether the input cable has short-circuited.

The power switch is turned on, but

the fan isn’t revolving or only

revolving slowly; there is no cutting

voltage output.

It may be wrongly connected to the 380V power supply, thus causing the

over-voltage protection to kick in. Re-connect it to a 220V power supply, then

restart the machine.

The fan is on and the warning pilot

light is not on; no HF electricity being

emitted; cannot start the arc.

The voltage from the power board to the MOSFET should be about DC308.

−Whether it short-circuited or whether the bridge wire is well- connected.

−There are four capacitors on the bottom board, one of which may be

leaking; just replace it.

The assistant power supply is abnormal, it should be DC24V.

Check all of the connections in the machine.

Something is wrong with the control circuit, find the problem or contact the

seller.

The warning pilot light is off; no

sound when electricity has been

released; no cutting voltage output.

The welding cable is broken.

The earth cable is broken or it is not connected to the work piece.

The “+” output terminal is not connected well.

The warning pilot light is not on; no

sound when electricity has been

released.

The primary wires of the transformer and the power board are not well-

connected; re-connect them.

The nozzle has been oxidised or too far away; remove the oxidisation on the

surface. Place the distance to 1mm.

The warning pilot light is on It may be due to the over-charge protection kicking in. Please turn off the

power until the warning pilot light is off, and let the machine recover.

It may be due to the over-charge protection kicking in. No need to turn it off,

just wait for two or three minutes; or there may be something wrong with the

inverter circuit. If so, unplug the power plug on the MOSFET of the main

transformer, and then restart the machine.

−If the warning pilot light is still turned on, turn off the machine and unplug

the HF arc-leading power plug, and then restart the machine.