SA-02N

Supervised Wireless Magnetic Contact Sensor

Installation Manual

1

1. General Description

The SA-02N Supervised Wireless Magnetic Contact Sensor is a high-

performance intrusion sensor, developed with the highest level of

technology to make it ideal for residential and commercial applications.

1.1 Standard Features

Supervisor

Case and Back Tamper Detectors

ASIC and Microprocessor Technology

Up to 3-year battery life with SPS

Ultra-low current consumption

Readily replaceable 3.6 V – 1/2 AA Lithium battery

SMD component technology

LED Test Function

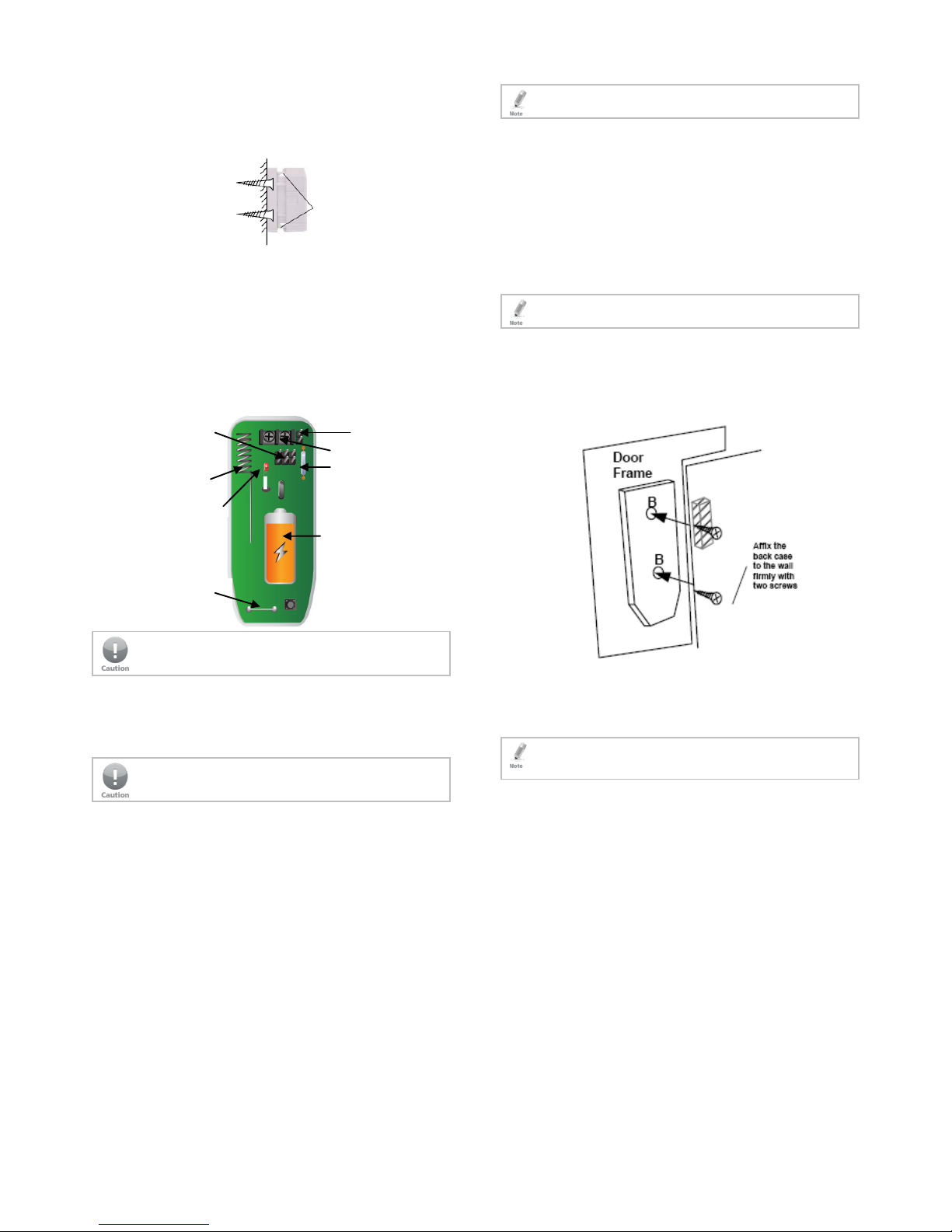

Figure 1: SA-02N

2. Technical Specifications

2.1 Electrical Characteristics

Battery CR123A 3V 1400 mAh (low battery signal when V =

2.5 V)

Current Standby – 3 to 8 uA; Transmit – 5 mA

Pulse Count Fixed at single pulse

Detect Range Sensitivity of up to 2 cm from magnet

Alarm Transmit One second

Indication LED EN/DIS

2.2 Physical Characteristics

Dimensions (H x W x D): 87 x 35 x 25 mm (3.5 x 13.8 x 1 in.)

Weight 37 g (1.30 oz) without battery

Standards FCC, CE, EN 50131-2-6, EN 50131-6, EN 50130-5,

EN 50130-4, Security Grade 2, Environmental Class

II

2.3 Environmental Characteristics

Operating Temperature

Range

-20°C to 50°C (-4°F to 122°F)

Operating Humidity

Range

Up to 95% (non-condensing) (max.)

RF Frequency Available in 433.92 MHz or 868.35 MHz, with 1 m

Watt

Installation Indoor

Magnet Standard magnet with plastic housing and wall

spacer, adjustable height

Tamper Switch 1 Detects removal of Magnetic Contact Sensor Front

Cover (protected by case tamper switch)

Tamper Switch 2 Detects removal of Magnetic Contact Sensor from

the wall or from corner mount (protected by rear

tamper switch)

Supervisor The supervisory signal is routinely transmitted to the

panels every 20 minutes, advising the Tamper

Status, Battery Status, and Event Activation Status to

the panel

3. Installation Recommendations

The SA-02N Magnetic Contact Sensor detects the opening and closing

of doors and windows, and transmits this information to the receiver

panel.

AVOID placing the Magnetic Contact Sensor near strong magnetic

or electrical fields other than the magnet with which it is intended

to be used; otherwise, performance may be affected and false

alarms may occur.

AVOID mounting on or near large metal surfaces and multiple

concrete/steel walls, as this may interfere or block the wireless

signals. Make sure to test the range from any location by using the

RF Test Procedure to ensure reception.

Install the magnetic contact sensor on windows or doors that

have firm hinges and firm locking action to prevent false

alarms associated with wind or bumping.

4. Installation Instructions

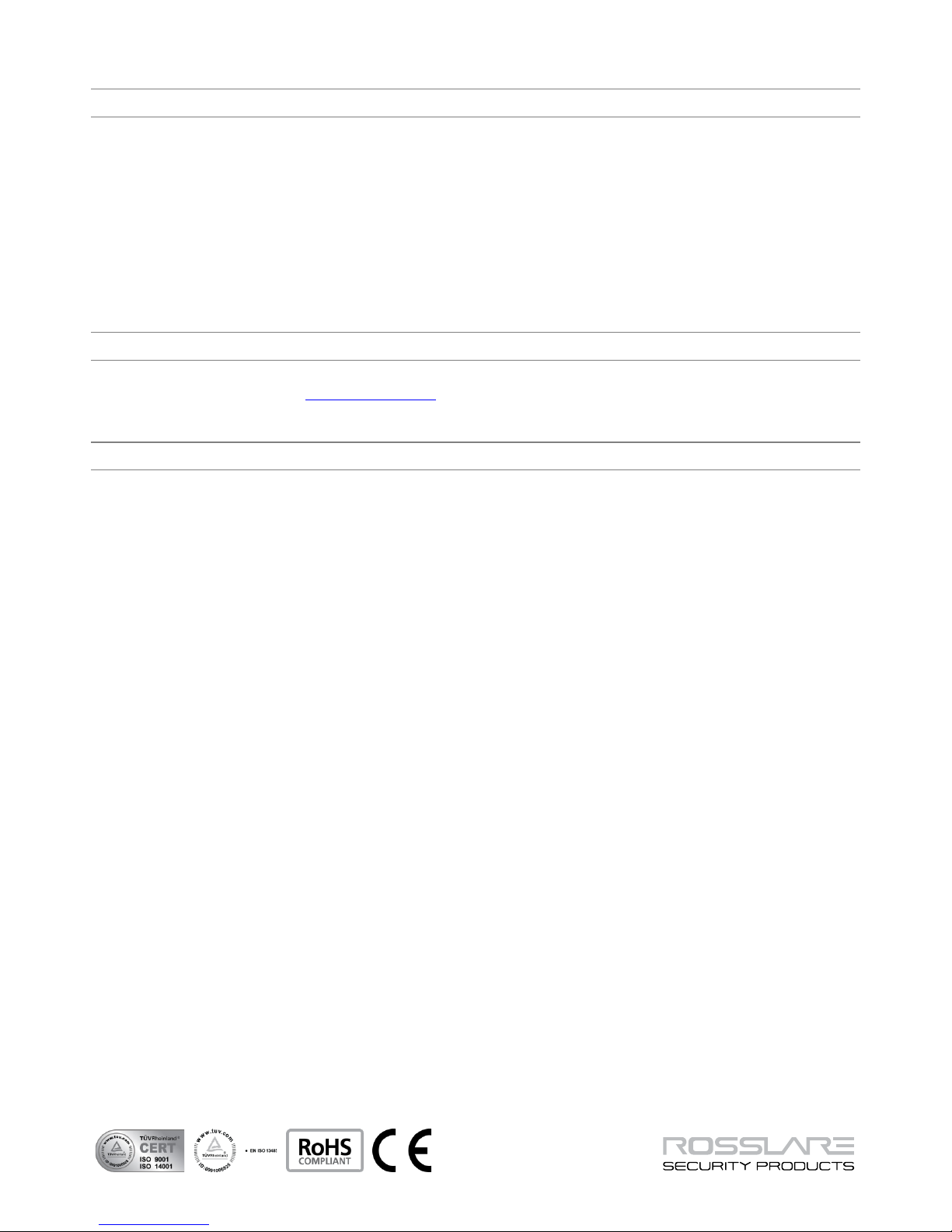

4.1 Selecting the Location

The location and mounting of the SA-02N affects both the

transmission range and the wear and tear of the transmitter. Preferably

the transmitter should be installed as close as possible to the receiver,

and mounted in a high location so that the transmission has less

interference.