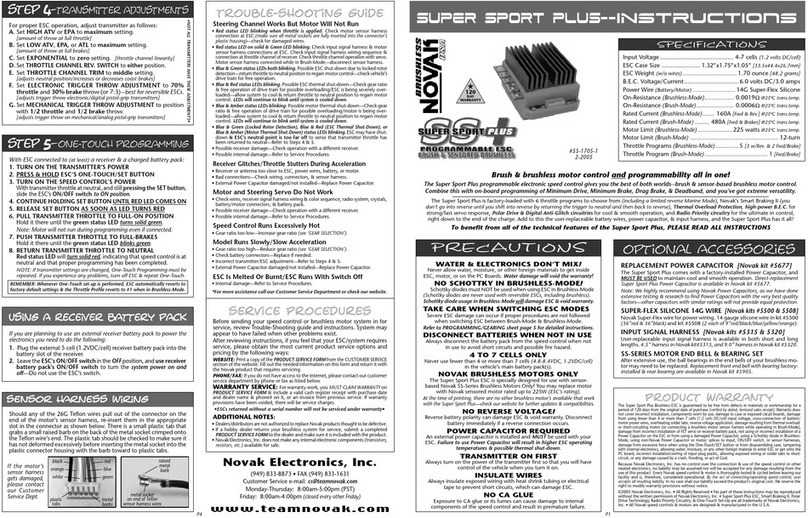

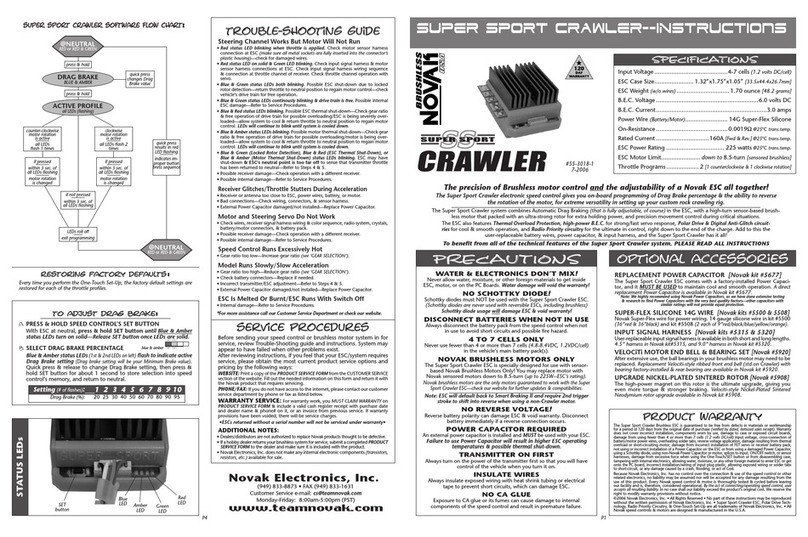

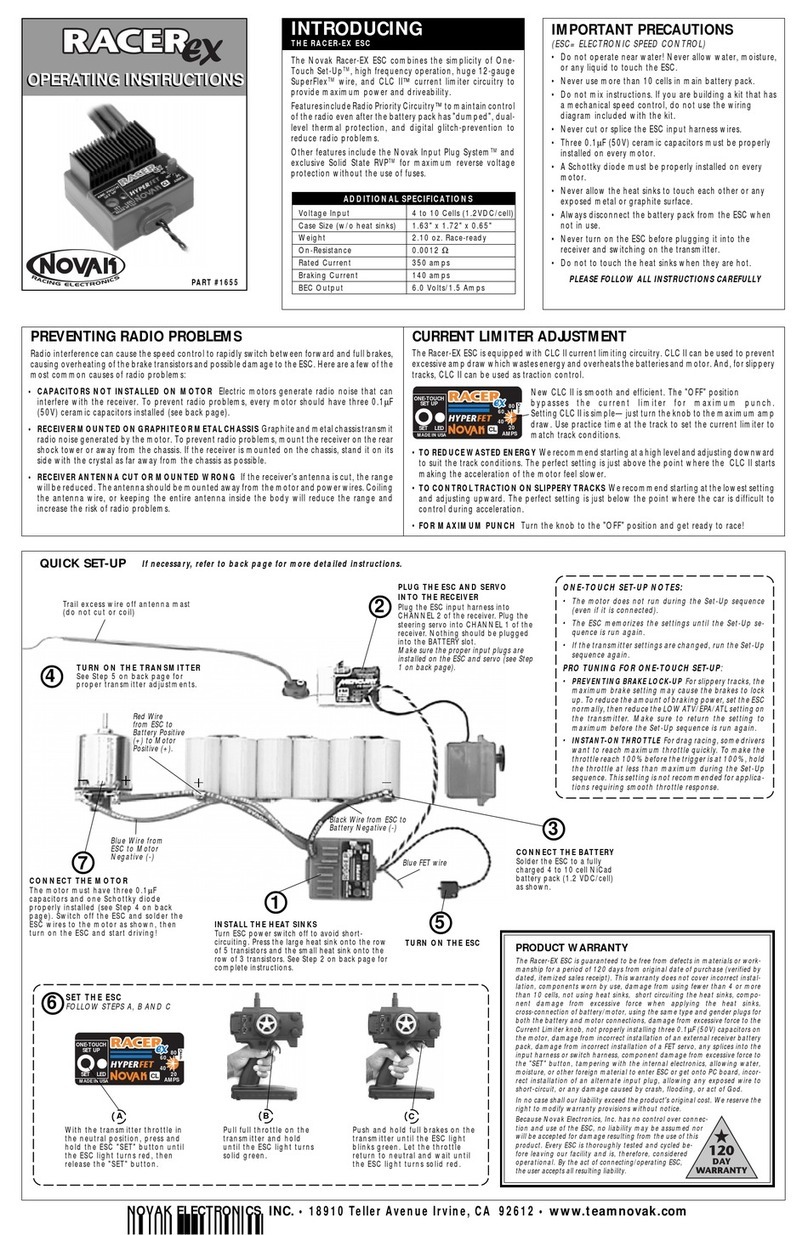

SPECIFICATIONS

PRECAUTIONS

ESC Input Voltage 4-6 cells (1.2 volts DC/cell)

ESC Power Rating 225 Watts @ 25

°

C trans.temp.

ESC B.E.C. Voltage/Current 6.0 volts DC/1.5 amps

ESC Throttle Modes 2 (1 w/Rev. & 1 Fwd/Brk)

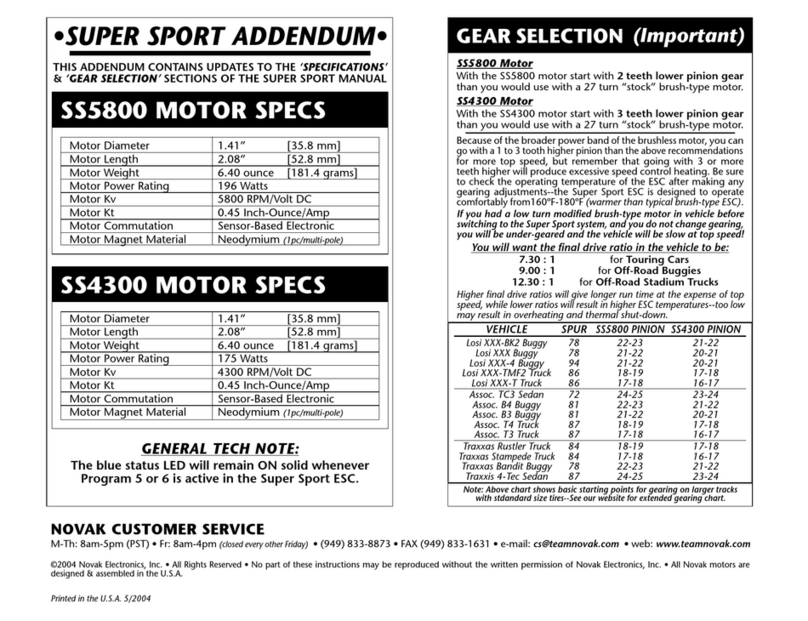

Motor Diameter 1.41” [35.8 mm]

Motor Length 2.08” [52.8 mm]

Motor Turns 10 1/2

Motor Kv 4300 RPM/Volt DC

Motor Kt 0.45 Inch-Ounce/Amp

Motor Commutation Sensor-Based Electronic

Motor Magnet Material Neodymium (1pc/multi-pole)

• DISCONNECT BATTERIES WHEN NOT IN USE Always

disconnect the battery pack from the speed control when not

in use to avoid short circuits and possible fire hazard.

• WATER & ELECTRONICS DON’T MIX! Never allow water,

moisture, or other foreign materials to contact ESC or motor.

• 4 TO 6 CELLS ONLY Never use fewer than 4 or more than 6

cells (7.2 volts DC) in the main battery pack.

• POWER CAPACITOR REQUIRED The attached external power

capacitor MUST be used with the Super Sport 10.5.

Failure to use Power Capacitor will damage speed control and

void the warranty!

• CHANGING VEHICLE GEARING CAN CAUSE OVERHEATING

The Super Sport 10.5 has been specially built for this vehicle’s

stock gearing--any changes may result in thermal shut-down.

•CHECK MOTOR SCREWS Check all motor screws for

loosening. The 3 long main screws on the shaft end of motor

& the 3 flat head screws on the back end may loosen after a

few runs of the motor, and need tightening.

• NOVAK MOTORS ONLY The Super Sport 10.5 ESC has been

specially designed for use with sensor-based Novak Brushless

Motors Only! You may replace motor with any Novak sensored

brushless motor with 10

1/2turns or more.

• NO REVERSE VOLTAGE! Reverse battery polarity will damage

the speed control and void the warranty.

• NO SCKOTTKY DIODE! Never use Schottky diodes with

brushless ESCs--use will damage ESC & void warranty.

• TRANSMITTER ON FIRST Always turn on the power of your

transmitter first so that you will have control of the radio

equipment when you turn on the speed control.

• INSULATE WIRES Always insulate exposed wiring with heat

shrink tubing to prevent short circuits.

• NO SOLVENTS Exposing the speed control or motor to any

type of solvents can damage the exposed material.

• NO CA GLUE Never use cyano-acrylate (CA) glue on the

speed control or motor. Exposing the ESC or motor to CA

glue will damage the electronics and void the warranty.

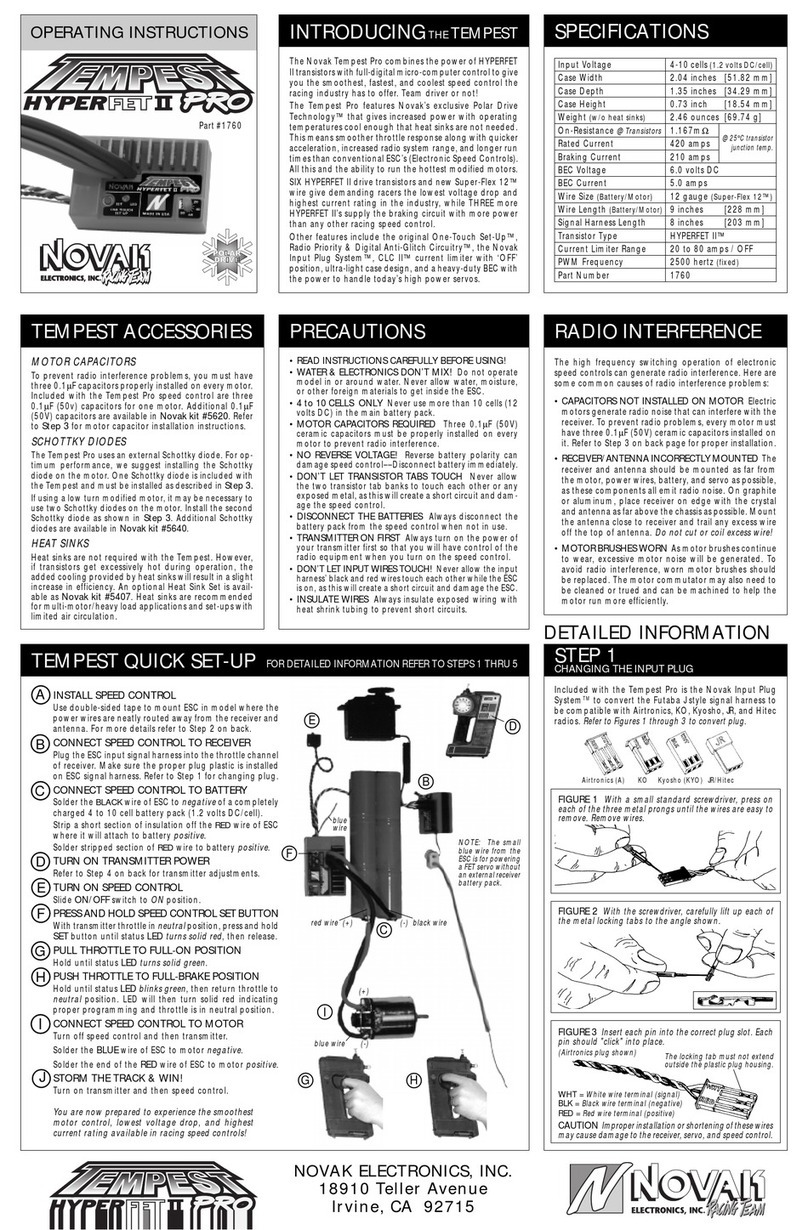

OWNER’S MANUAL

SUPER SPORT 10.5 ESC & SS4300 MOTOR

Novak Sensor-Based Brushless Motor System

Congratulations on your purchase of a vehicle that is

equipped with a state-of-the-art sensor-based brushless

mo-

tor system. Now you too will enjoy the low-maintenance,

high-efficiency performance of brushless motors that are de-

signed specifically for R/C cars.

We’ve combined the racing technology of our top of the

line speed controls with the efficiency of sensor-based

brushless motors to bring you the Super Sport 10.5 Brushless

Electronic Speed Control (ESC) & the SS4300 Brushless Motor,

giving you a sport-level brushless system with excellent low

speed driveability, extended run time, great torque available

over a broad power band, and Novak relaibility.

Equipped with Novak’s Variable Throttle Step Technology for

the smoothest throttle response, One-Touch Set-Up for ease

of programming, and the security of Radio Priority Circuitry,

the Super Sport 10.5 has it all!

Benefits of sensor-based brushless motor design:

• CONSTANT ROTOR POSITION KNOWLEDGE Always

knowing what angle the rotor is at, allows instantaneous

response and smooth transitions from neutral to drive.

• SMOOTH/CONTROLLED LOW SPEED DRIVEABILITY

Rotor positioning is key to smooth acceleration without

delivering abrupt and uncontrolled bursts of power.

• STRONG & CONSISTENT BRAKES & STARTING TORQUE

Rotor position knowledge results in consistent starts and stops,

without hesitation or inconsistent lag times before

acceleration or braking.

•

LOCKED ROTOR & THERMAL PROTECTION Temperature &

position sensors in motor provide unparalleled protection for

your investment. Allowing you to run pack after pack without

worrying about overheating the motor, ESC, or magnets.

ACCESSORIES

REPLACEMENT POWER CAPACITOR

[Novak kit #5677]

The Super Sport 10.5 comes with a factory-installed Power Capacitor,

and MUST BE USED to maintain cool/smooth operation--

Note: We highly

recommend using Novak Power Capacitors, as we have done extensive testing &

research to find Power Capacitors with the very best quality factors––other capacitors

with similar ratings will not provide equal protection. Larger Novak capacitors are OK.

Replacement Super Sport 10.5 Power Capacitor is available in kit #5677.

SUPER-FLEX SILICONE 14G WIRE

[Novak kits #5500 & 5508]

Novak Super-Flex power wire. 14 gauge silicone wire in kit #5500

(36”red

& 36”black)

and kit #5508

(2 each of 9”red/black/blue/yellow/orange)

.

INPUT SIGNAL HARNESS

[Novak kits #5315 & 5320]

User-replaceable input signal harness is available in both short & long

lengths. 4.5” harness in Novak kit #5315, and 9.0” harness in kit #5320.

SS4300 MOTOR BEARING SET

[Novak kit #5904]

After extensive use, the ball bearings in the end bells of your brushless

motor may need to be replaced.

Replacement front & rear bearings are available in Novak kit #5904.

SERVICE PROCEDURES

Before sending in your Super Sport 10.5 brushless speed control or

SS4300 brushless motor for service, review the Trouble-Shooting

Guide and Owner’s Manual. The ESC or motor may appear to have

failed when other problems exist.

After reviewing the Owner’s Manual, if you feel the system requires

service, please obtain the most current product

service options and

pricing by one of the following methods:

WEBSITE: Print a copy of the PRODUCT SERVICE FORM from SERVICE

section of the Novak website. Fill out needed information on form

and return it with the Novak product requiring service.

PHONE/FAX: If you do not have access to the internet, contact

our customer service department by phone or fax as listed in the

CUSTOMER SERVICE section below, and they will supply you with

current service options.

WARRANTY SERVICE: To receive warranty work, you MUST CLAIM

WARRANTY on the PRODUCT SERVICE FORM & include a valid,

itemized cash register receipt with purchase date on it, or invoice

from previous service work.

ADDITIONAL NOTES:

•The Super Sport 10.5 speed control and the SS4300 brushless

motor should be returned together.

• Hobby dealers or distributors are not authorized to replace Novak

products thought to be defective.

• If a hobby dealer returns your speed control & motor for service,

submit a completed PRODUCT SERVICE FORM to the dealer and

make sure it is included with the items.

• Novak Electronics, Inc. does not make any electronic components

(transistors, resistors, etc.) available for sale.

PRODUCT WARRANTY

The Super Sport 10.5 brushless ESC & SS4300 brushless motor are guaranteed to

be free from defects in

materials or workmanship for a period of 120 days from the

original date of purchase

(verified by dated, itemized sales receipt). Warranty does not

cover incorrect installation,

components worn by use, damage from using fewer

than 4 or more than 6 cells (1.2 volts DC/cell) input voltage, cross-connection of

battery/motor power wires,

overheating solder tabs, reverse voltage application,

damage resulting from thermal

overload, damage from incorrect installation of

FET servo or receiver battery pack, not installing or incorrect installation of a Novak

power capacitor on the ESC,

splices to input harness, damage from excessive force

when using the One-Touch/SET

button or from disassembling case or motor, tam-

pering with internal electronics,

allowing water, moisture, or any other foreign

material to enter ESC or get onto the

PC board, incorrect installation/wiring of input

plug plastic, allowing exposed wiring

or solder tabs to short-circuit, or any damage

caused by a crash, flooding, or act of God.

In no case shall our liability exceed the product's original cost. We reserve the

right to modify warranty provisions without notice.

Because Novak Electronics, Inc. has no control over the connection and use

of the

speed control & motor or other related electronics, no liability may be assumed

nor will be accepted for damage resulting from the use of this product. Every

speed control & motor is thoroughly tested and cycled before leaving

our facility

and is, therefore, considered operational. By the act of connecting/

operating speed

control, the user accepts all resulting liability.

CUSTOMER SERVICE

NOVAK ELECTRONICS, INC.

Monday-Thursday: 8:00am-5:00pm (PST)

Friday: 8:00am-4:00pm

(949) 833-8873 • FAX (949) 833-1631

web: www.teamnovak.com

©2006 Novak Electronics, Inc. • All Rights Reserved • No part of this Owner’s Manual

may be reproduced without the written permission of Novak Electronics

, Inc. • Super

Sport 10.5 Brushless ESC, SS4300 Brushless Motor, Locked Rotor Detection Circuitry,

Variable Throttle Step Technology, Polar Drive Technology, Radio Priority Circuitry, &

One-Touch Set-Up are

all trademarks of Novak Electronics, Inc. • All Novak ESCs &

motors are designed &

assembled in the U.S.A.

Printed in the U.S.A. 2/2006 • #55-1010-1