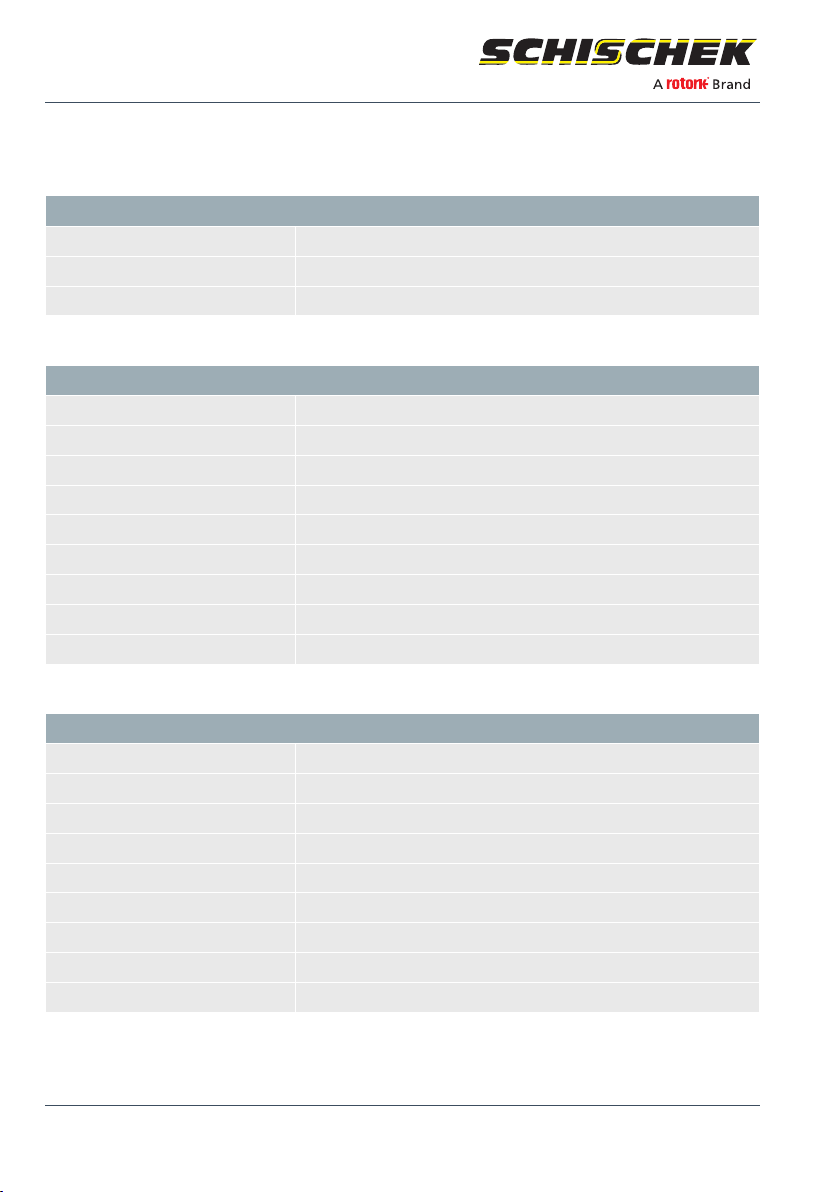

3.10.12 -Max-15-F1, Max-15-F1-CTS, Max-15-F1-VAS................................. 85

3.10.13 -Max-15-F, Max-15-F-CTS, Max-15-F-VAS....................................... 87

3.10.14 -Max-15-SF, Max-15-SF-CTS, Max-15-SF-VAS.................................. 89

3.10.15 -Max-15-SF1, Max-15-SF1-CTS, Max-15-SF1-VAS............................ 91

3.10.16 -Max-15-YF, Max-15-YF-CTS, Max-15-YF-VAS................................. 94

3.10.17 -Max-15-BF1, Max-15-BF1-CTS, Max-15-BF1-VAS........................... 98

3.10.18 -Max-15-BF, Max-15-BF-CTS, Max-15-BF-VAS................................. 100

3.10.19 -Max-15-BF-TR................................................................................ 103

3.10.20 -Max-15-CYF, Max-15-CYF-VAS...................................................... 105

3.10.21 -Max-15.30, Max-15.30-CTS, Max-15.30-VAS................................. 107

3.10.22 -Max-15.30-Y, Max-15.30-Y-CTS, Max-15.30-Y-VAS...................... 109

3.10.23 -Max-15.30-S, Max-15.30-S-CTS, Max-15.30-S-VAS........................ 112

3.10.24 -Max-15.30-R, Max-15.30-R-CTS, Max-15.30-R-VAS....................... 114

3.10.25 -Max-15.30-CY............................................................................... 117

3.10.26 -Max-8-F1, Max-8-F1-CTS, Max-8-F1-VAS....................................... 119

3.10.27 -Max-8-SF1, Max-8-SF1-CTS, Max-8-SF1-VAS.................................. 121

3.10.28 -Max-8-BF1, Max-8-BF1-CTS, Max-8-BF1-VAS................................. 124

3.10.29 -Max-30-BF, Max-30-BF-CTM.......................................................... 126

3.10.30 -Max-30-BF3, Max-30-BF3-CTM...................................................... 129

3.10.31 -Max-30-F, Max-30-F-CTM.............................................................. 131

3.10.32 -Max-30-F3, Max-30-F3-CTM, Max-30-F3-VAM.............................. 133

3.10.33 -Max-30-SF, Max-30-SF-CTM, Max-30-SF-VAM............................... 135

3.10.34 -Max-30-SF3, Max-30-SF3-CTM, Max-30-SF3-VAM......................... 137

3.10.35 -Max-30-YF, Max-30-YF-CTM, Max-30-YF-VAM.............................. 140

3.10.36 -Max-50-BF, Max-50-BF-CTM.......................................................... 143

3.10.37 -Max-50-BF3, Max-50-BF3-CTM...................................................... 146

3.10.38 -Max-50-F, Max-50-F-CTM.............................................................. 148

3.10.39 -Max-50-F3, Max-50-F3-CTM.......................................................... 150

3.10.40 -Max-50-SF, Max-50-SF-CTM, Max-50-SF-VAM............................... 151

3.10.41 -Max-50-SF3, Max-50-SF3-CTM, Max-50-SF3-VAM......................... 155

3.10.42 -Max-50-YF, Max-50-YF-CTM.......................................................... 158

3.10.43 -Max-60-BF..................................................................................... 161

4 Translation of the original installation guide · Version 1.0 · 2021-05-27