Gearbox ILG/D manual

Rotork Gears bv

Installation en operating

Not observing the rules as stated in this manual, can lead to damage and/ or personal injuries. The qualified

personnel must be fully aware of the instructions as described in this manual.

Only when the instructions are observed, correct operation of the gearboxes can be guaranteed.

Disposal

Never dispose a gearbox at a general disposal site/depot. The gearbox has to be offered to a disposal depot for

recycling. The iron parts can be used for recycling. The seals are of nitrile and can be used for plastic recycling.

The grease may not be discharged to sewer- or surface water. It has to be disposed according to local regulations

for incineration.

2. Installation : mounting to the valve.

The ILG/D is a manual declutchable override quarter turn gearbox for double acting actuators.

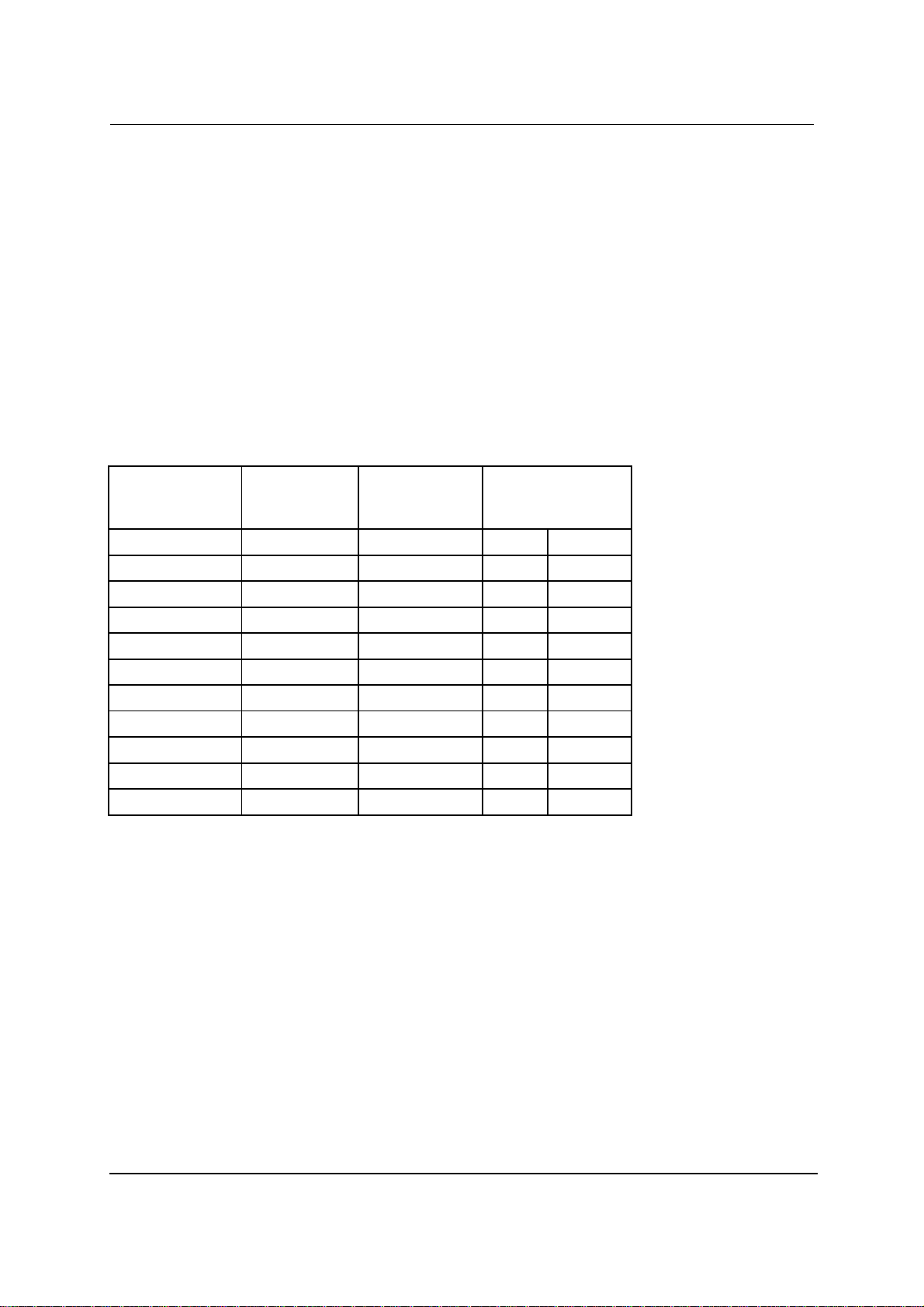

For connection data, maximum allowable input- and output torque refer to table 1.

This manual describes the installation of the gearbox and its parts. The intention of the ILG/D gearbox is to

operate the valve in case of a failing actuator system.

1. The gearbox is standard delivered in the closed position.

2. It is recommended to mount a handwheel on the insputshaft, before assembling the gearbox to the

valve.

3. Check if the boltcircle of the flanges (of gearbox and valve) coincide. Also check if the valvestem and

the bore at the bottom of the gearbox match.

4. Make sure the valve is in the closed position. If not, close the valve before continuing.

5. Check if the gearbox is in fully closed position by turning the handwheel clockwise.

6. In case of use of studbolts for fixing the gearbox to the valve, it is recommended to screw them into the

bottomflange of the gearbox before mounting the gearbox to the valve.

7. The use of a gasket between the flange of the valve and gearbox is recommended.

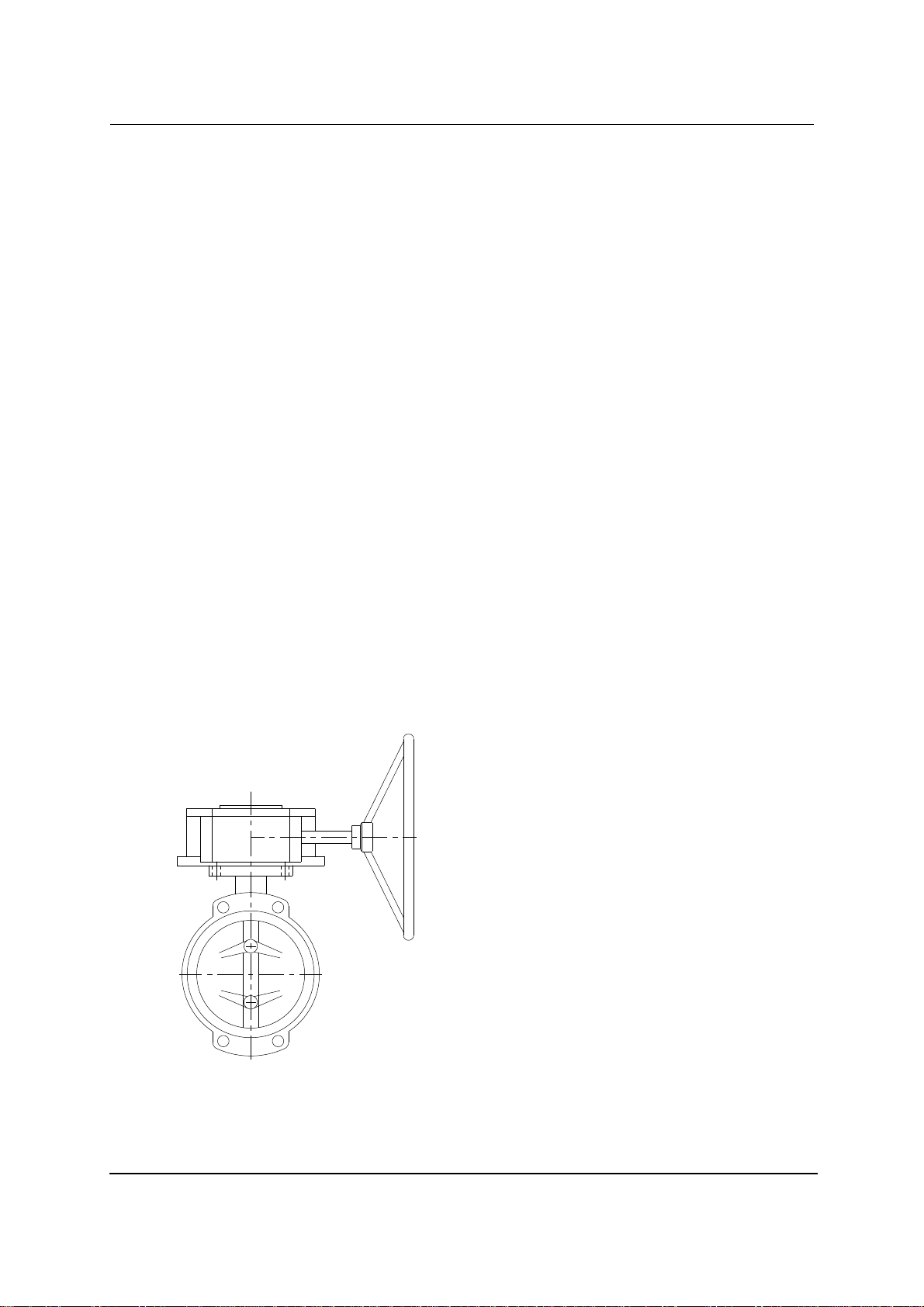

8. The gearbox is mounted perpendicular to the valve (see figure 1).

figure 1 : Gearbox perpendicular to the valve