2200004 _7225 2018 04 20 English

EN

These instructions for use are intended for users

of Rototilt®. The user is expected to have basic

knowledge of mechanics, hydraulics and electronics.

The instructions for use belong with the Rototilt®and

should always be kept readily at hand in the driver’s

cab. If the instructions for use are lost, new ones

must be acquired immediately.

Document structure

These instructions for use are divided into chapters.

The Safety Instructions section contains information

important for preventing the risk of personal injuries.

IMPORTANT!

Read the safety instructions carefully

before using Rototilt®.

There is information in the Description chapter about

how Rototilt®is built and functions.

Under Handling information, Maintenance,

Troubleshooting and Diagrams there are

step-by-step instructions for the use and

maintenance of Rototilt®.

To ensure the best possible performance, economy

and long service life, follow all instructions in this

manual correctly.

This will also prevent the most common causes of

accidents that occur during use or maintenance.

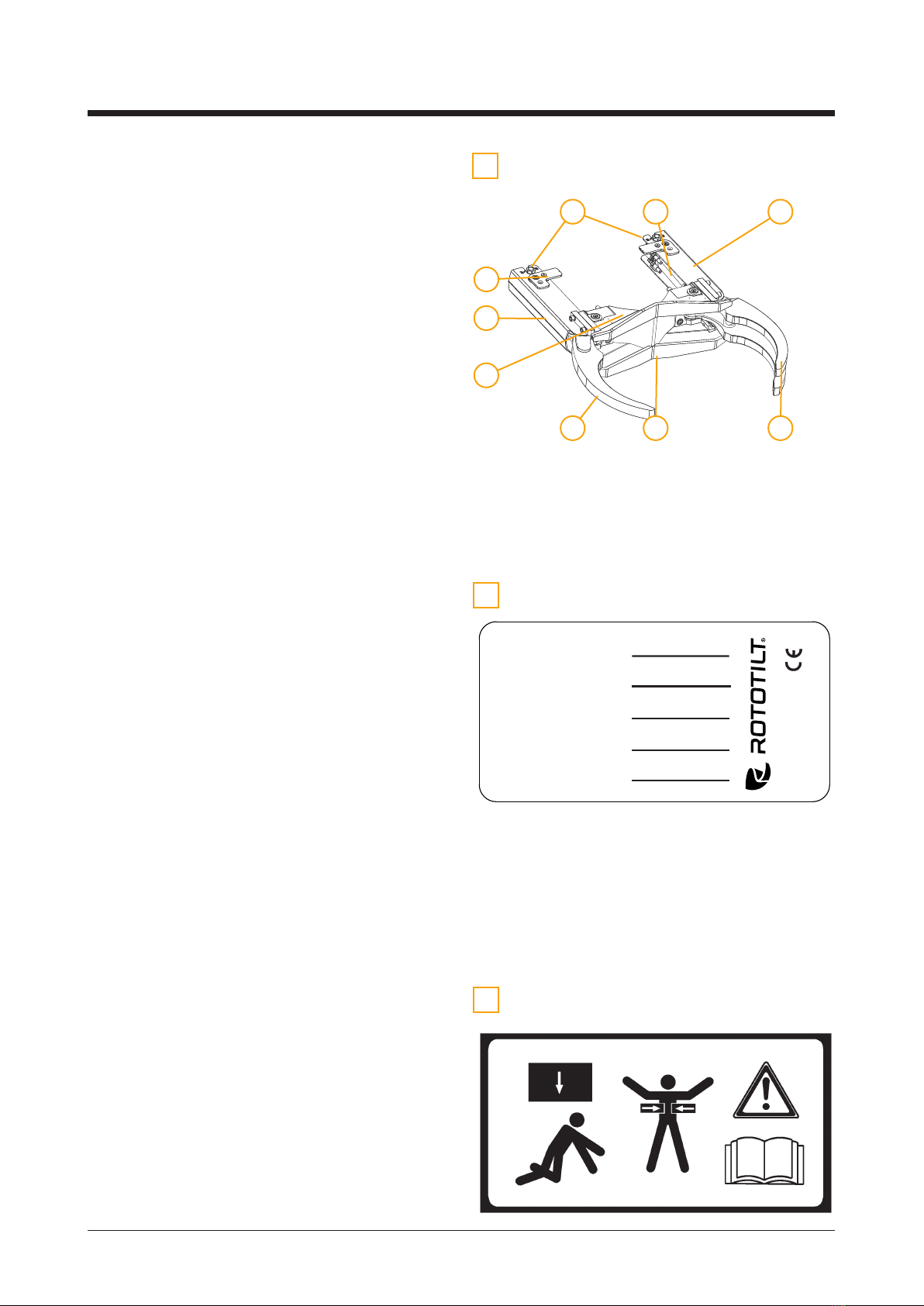

CE marking

Rototilt®is CE marked, which means it is designed,

produced and described in accordance with EC

Directives.

If Rototilt® is modied, supplemented with other

products or used in applications for which the

product is not approved, this marking will cease

to be valid.

Warranty and warranty claims

Contact your dealer.

Other information

Spare parts lists and repair instructions are available

from your Rototilt®dealer.

This information is correct at the time of going to

print. All possible measures have been taken to

ensure that the content is as complete and accurate

as possible. In spite of this, no responsibility can be

taken for missing or incorrect information.

The manufacturer reserves the right to implement

improvements at any time without altering the basic

function of the model, with the aim of further Rototilt®

development

This may occur without necessarily updating these

instructions for use. Contact the nearest dealer in

order to obtain information about possible changes.

No part of this publication may be reproduced,

translated, stored or communicated electronically,

mechanically, photographically or in any other way

without prior written consent from Rototilt Group AB.

This provision covers the contents in whole or in

part, regardless of whether the contents are used in

other publications or not.

Introduction