© Rototilt Group AB 2018-06-28

!

PULSATING

LIGHT

FIXED

LIGHT

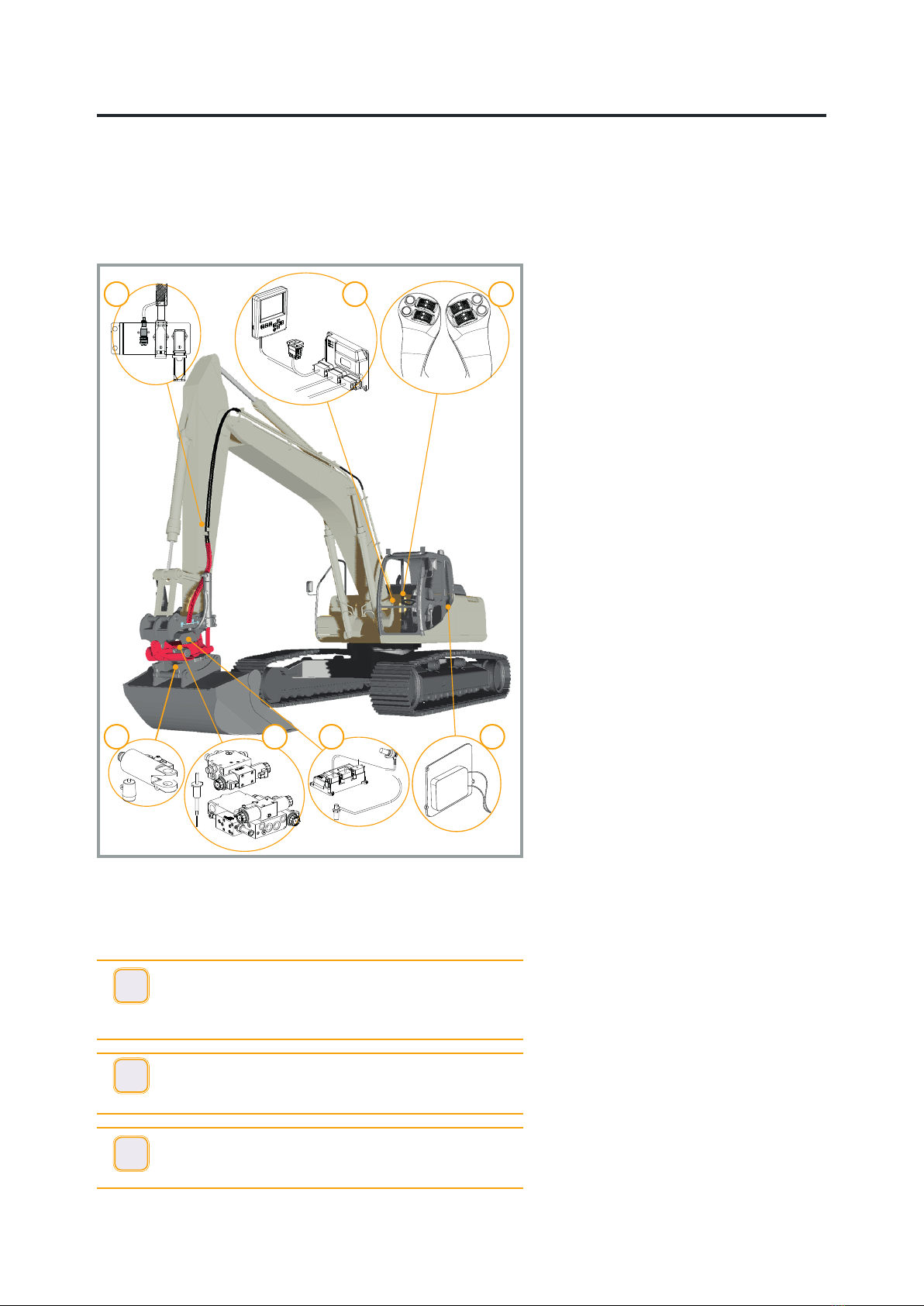

TCU

CCU

Sound

Light

Power

CAN-bus

Internal

Error

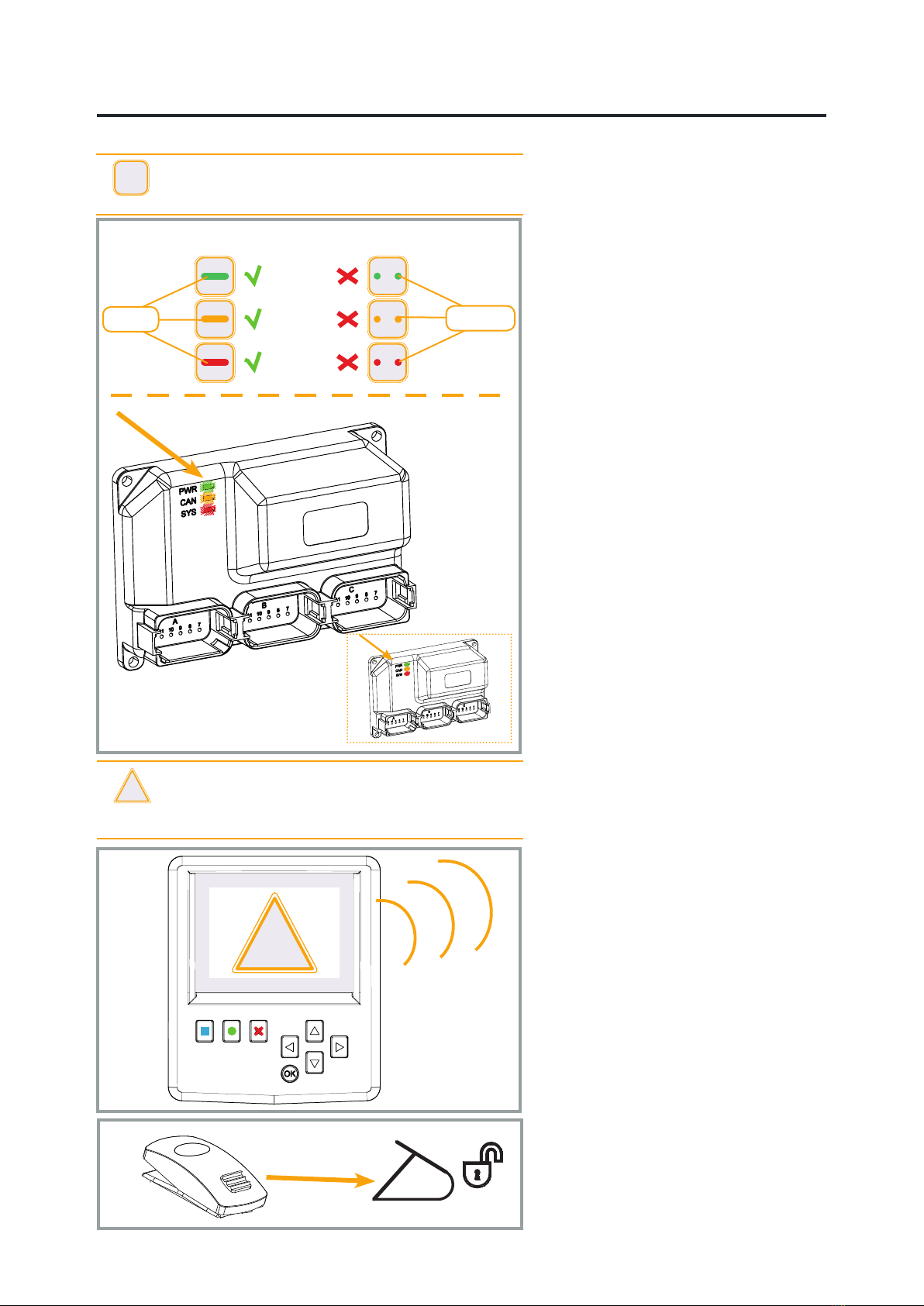

LED INDICATIONS

OK Error

EN English

Control unit

The control units have three LEDs:

green, orange and red. When the system

is working correctly, all LEDs light and

with no ashing.

When a malfunction occurs the relevant

LED begins ashing.

PWR (green) shows whether the unit is

powered up.

CAN (orange) shows whether

communications with CAN bus are

working.

SYS (red) shows whether the unit’s

internal components are working

correctly.

The control units are not interchangeable.

Cab control unit, CCU

The control unit receives signals from the

handles and switches.

The control unit sends signals to the

valve block shunt and tiltrotator via CAN

bus.

Rototilt® control unit, TCU

The control unit receives signals from

the cab control unit, and from sensors in

Rototilt®.

Rototilt® control unit sends signals to

valves and LED lamp.

There is a sensor in the Rototilt® control

unit that detects the tilt angle.

!

IMPORTANT - The control units have a similar

appearance but the content differs. They are not

interchangeable.

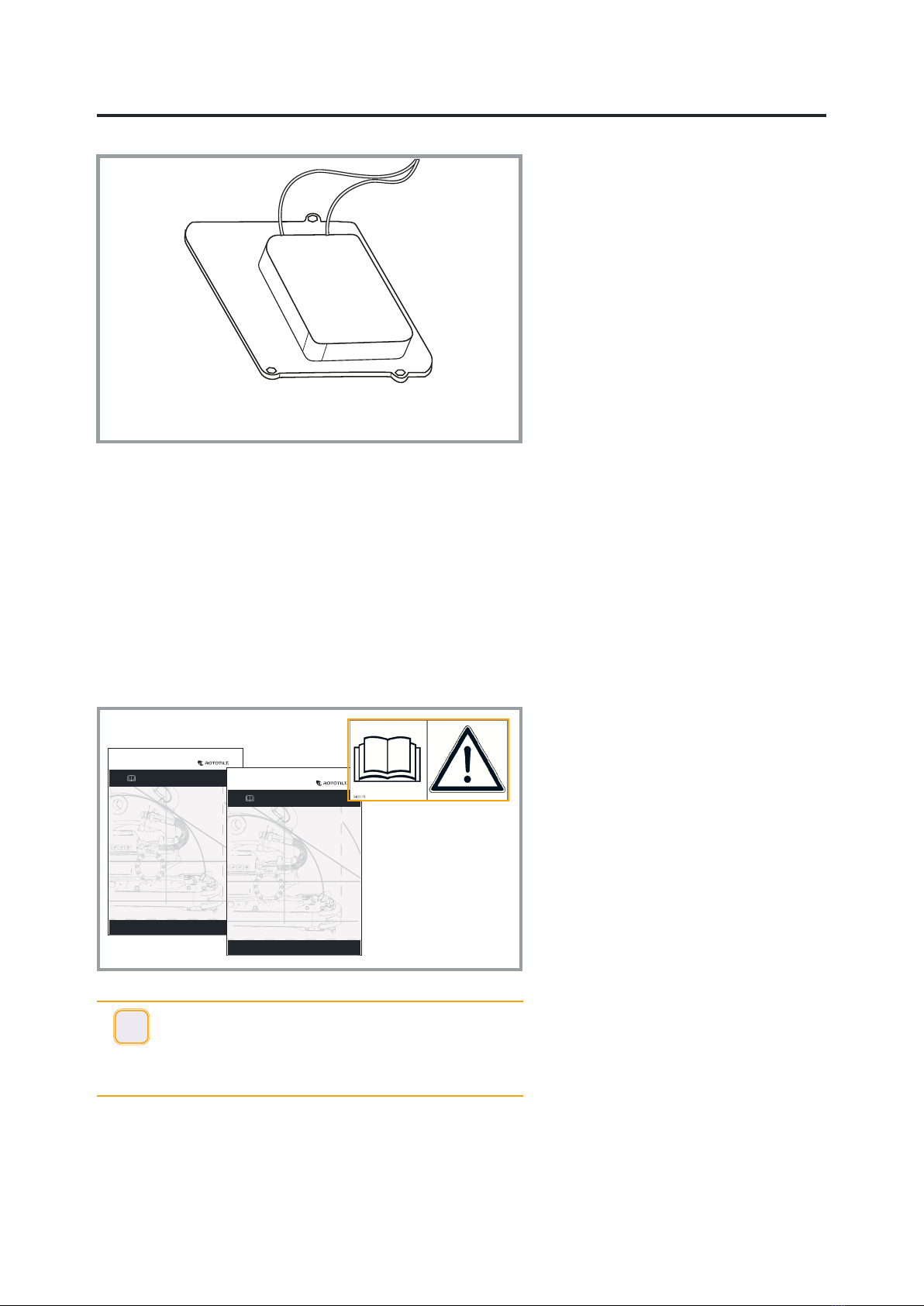

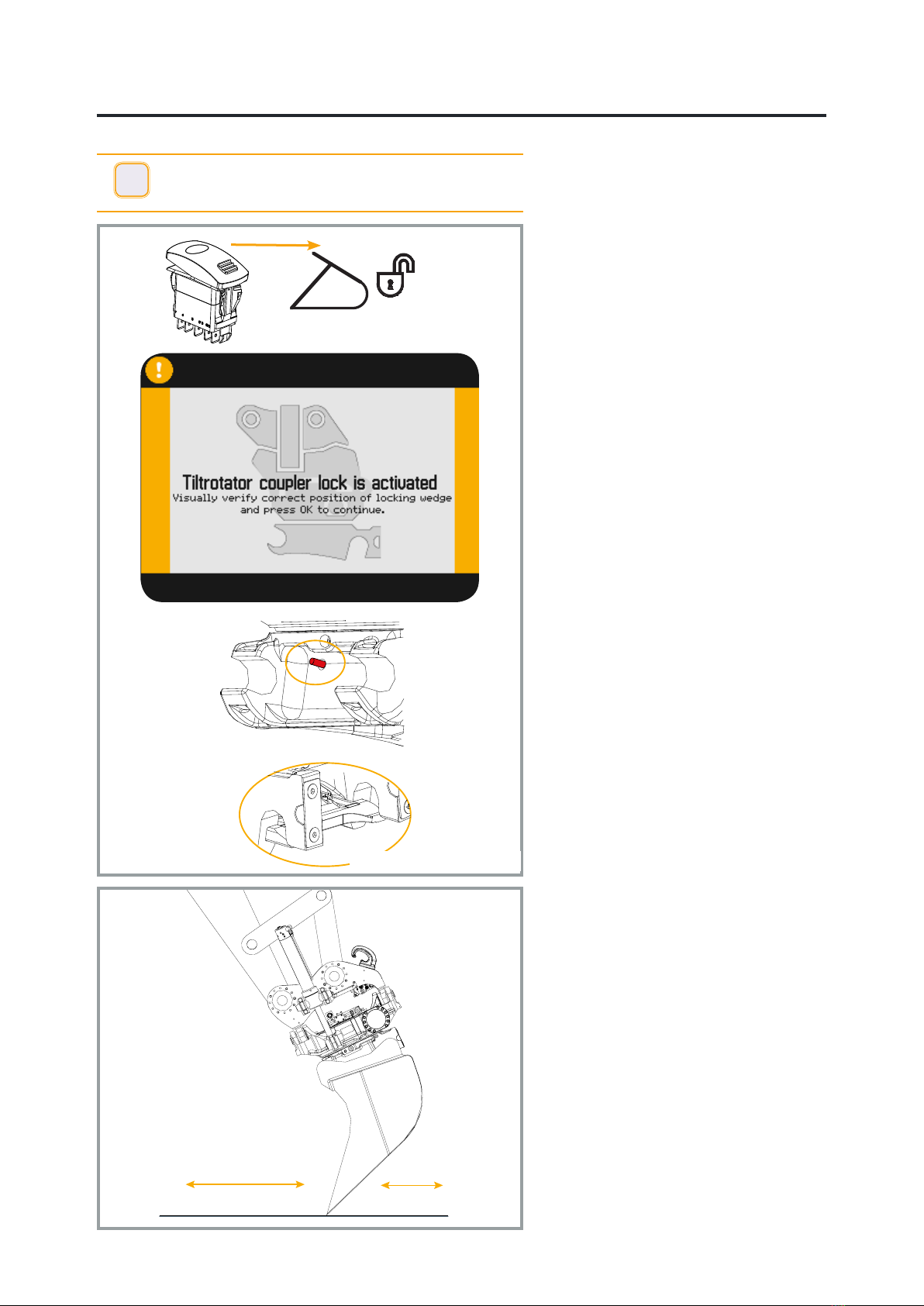

Display

Settings, calibration and activation of

certain functions are made via the display

and its keys.

There is a buzzer in the display that

sounds to attract the operator’s attention

if the quick coupler locking function is

open or in the event of a fault.

Switch, quick coupler locking

function

The quick coupler locking function switch

is interlocked. This prevents accidental

activation of the quick coupler locking

function.

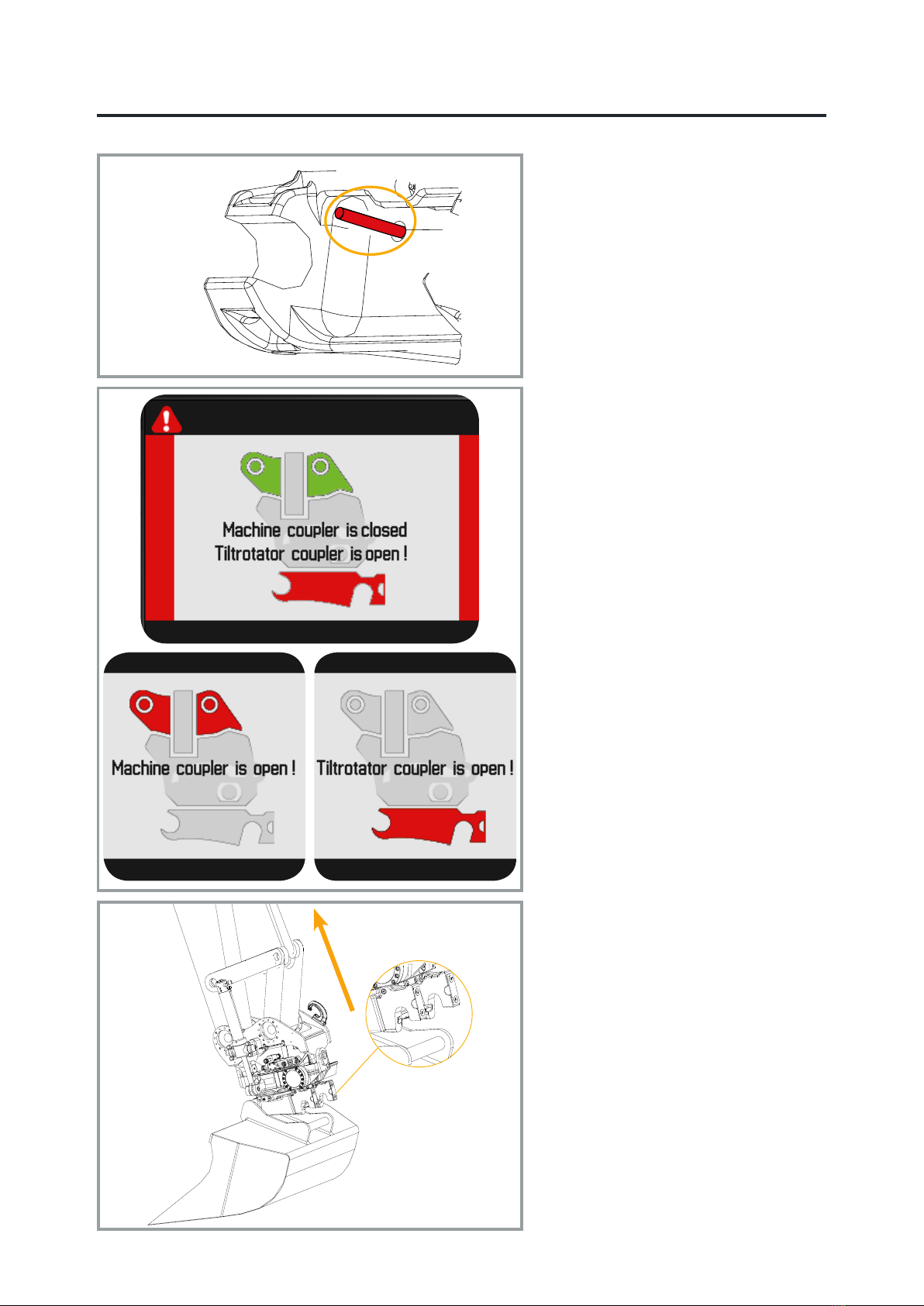

!

WARNING! A problem has occurred if the buzzer

sounds without activating the quick coupler locking

function switch. The display shows information

about the current problem.