Rev. 1.6

WWW.ROTREX.COM Page 9 of 41

Choosing the right Rotrex

3. Choosing the right Rotrex

3.1 General guidelines

1 Power output is dependent on engine type, cooling of charge air, cam profile and timing, compression ratio

etc.

2 CCW: Counter Clock Wise rotation direction seen from the pulley side

3 CW: Clock Wise rotation direction seen from the pulley side

The amount of air delivered by the supercharger and consequently the boost pressure is

determined by the supercharger model and the impeller speed in conjunction with the

engine size and speed. The comparison table above shows the working area of each

supercharger model within the C-range. For compressor maps please refer to the

technical datasheets. If in doubt, please contact your Rotrex supplier.

Regardless of the supercharger type and model, always make sure to run it within its

respective operating speed range specified in the technical datasheet. Exceeding these

speed values will void warranty.

The optimum supercharger for a given application will depend on many variables of which

some are hard to know accurately (e.g., volumetric efficiency or how this will be affected

under boost conditions). This can very well be modelled using advanced engine calculation

tools and theory. However, using a simple “rule of thumb” along with the information

provided here and in the flow maps will be adequate in many cases.

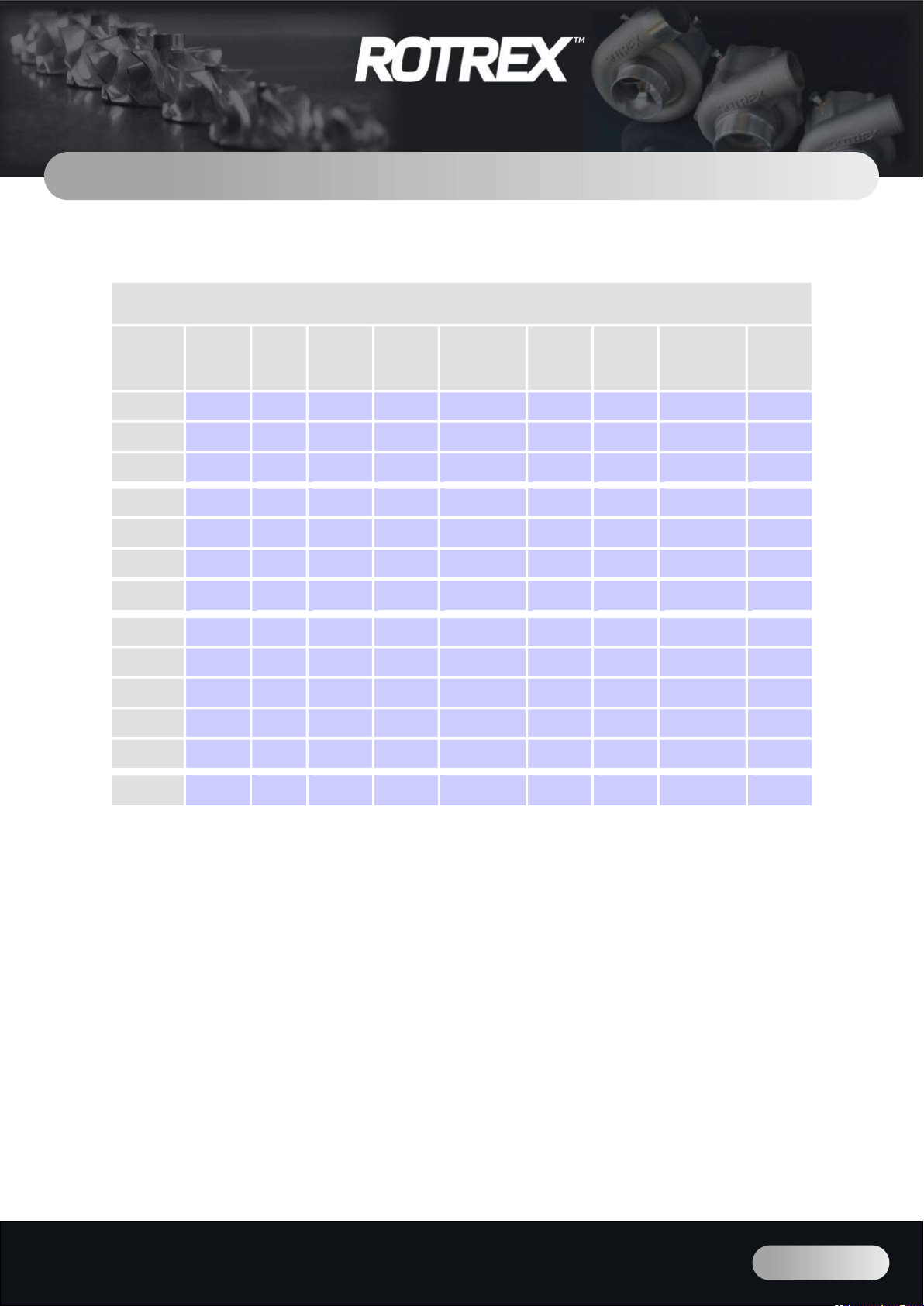

Supercharger comparison table

Model

Input

rotation

direction

Pulley

dia.

[mm]

Air inlet

hose dia.

[mm]

hose dia.

[mm]

speed

[rpm]

Max

pressure

ratio

Max flow

[kg/s]

Power range1

[engine kW]

Max

[%]

C15-16 CW3 70-90 60 45 201,500 2.46 0.15 60-125kW

(82-170hp) 70

C15-20 CW3 70-90 60 45 180,000 2.94 0.15 50-120kW

(68-163hp)

75

C15-60 CW3 70-90 60 45 150,000 2.34 0.22 90-175kW

(122-238hp)

74

C30-64 CW3 70-110

60 50 120,000 2.68 0.28 120-235kW

(163-320hp)

72

C30-74 CW3 70-110

60 50 120,000 2.82 0.31 135-255kW

(184-347hp)

72

C30-84 CW3 70-110

76 50 120,000 2.82 0.32 140-265kW

(190-360hp)

72

C30-94 CW

CCW2 70-110

76 50 100,000 2.52 0.39 145-320kW

(197-435hp) 71

C38-61 CW3 70-110

76 63 90,000 2.90 0.48 200-410kW

(272-557hp)

73

C38-71 CW3 70-110

76 63 90,000 2.82 0.55 210-455kW

(286-620hp)

75

C38-81 CW3 70-110

76 63 90,000 2.85 0.58 220-485kW

(300-660hp)

72

C38-91 CW3 70-110

76 63 90,000 2.94 0.63 260-530kW

(354-720hp)

75

C38-92 CW3 70-110

89 63 90,000 2.94 0.63 260-530kW

(354-720hp)

75

C38R-112

CW

CCW2 75-110

89 63 90,000 3.34 0.84 340-720kW

(455-965hp) 75