10 ROVERS NORTH, INC. 1319 VT ROUTE 128, WESTFORD, VT 05494 USA www.roversnorth.com (802) 879-0032

RNGWK90

DEFENDER 90 WOOD MODEL PARTS KIT

1

/

1

8th

SEMI

-

SCALE

REALISTIC DISPLAY

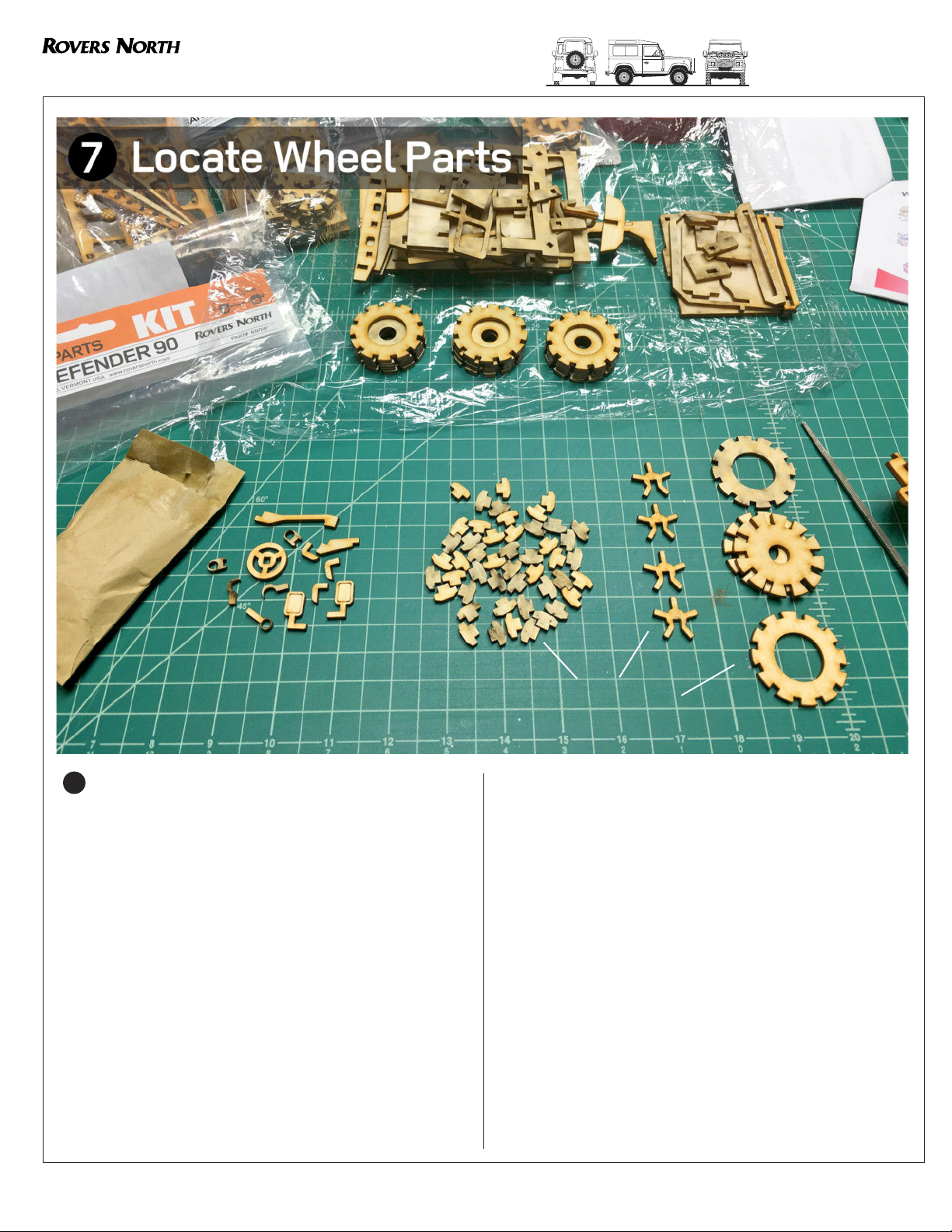

Bu ld Wheels steps 9B-9E

Start w th plac ng two wheel nner p eces together (9B)

and glu ng n each tread p ece unt l all 12 treads are fit as

shown. Make sure the tread p eces are centered, stra ght,

perpend cular to the wheel and n as far as they can go - all

the way down. Let dry.

Place glue around the edges of one s de and offer a

wheel outer p ece (sanded s de down - unsanded s de out)

to the wheel (9C). Th s w ll be the ns de of every wheel that

gets mounted to the axle.

Th s shows how the ns de of each wheel w ll look - th s

s the s de that mounts to the axle.

Th s shows the same as above (9D), but turned on the

s de. You w ll mount the wheel to the axle, then add the wheel

r m lock ng star on the axle hub and glue down the second

wheel outer p ece. See steps 9F-9I for final mount ng and

assembly.

8

B

C

D

E

Oops! Glued your fingers together?

Not to worry - don’t try to separate -

the glued bond w ll always w n!

You can use nail polish remover (acetone) to debond

your glued together fingers. Use the na l pol sh re-

mover n a well vent lated area, add a l ttle b t at a t me

unt l the bonded area starts to soen up. Keep add ng

the remover unt l you can free up your fingers. Th s

m ght take several appl cat ons and attempts, but the

remover w ll succeed n the end.

TIP: Wh le t’s a great exper ment to see how humans

rely on our opposable thumbs, I don’t recommend

gett ng your fingers stuck together w th super glue!

I’ve done t many t mes (by acc dent of course)

and when th s happens, t puts you nto a mass ve

pan c! You can definately feel that f you tr ed to pull

your fingers apart, your sk n w ll be the first to go.

Not a good feel ng at all.

Keep a bottle of nail polish remover close by.