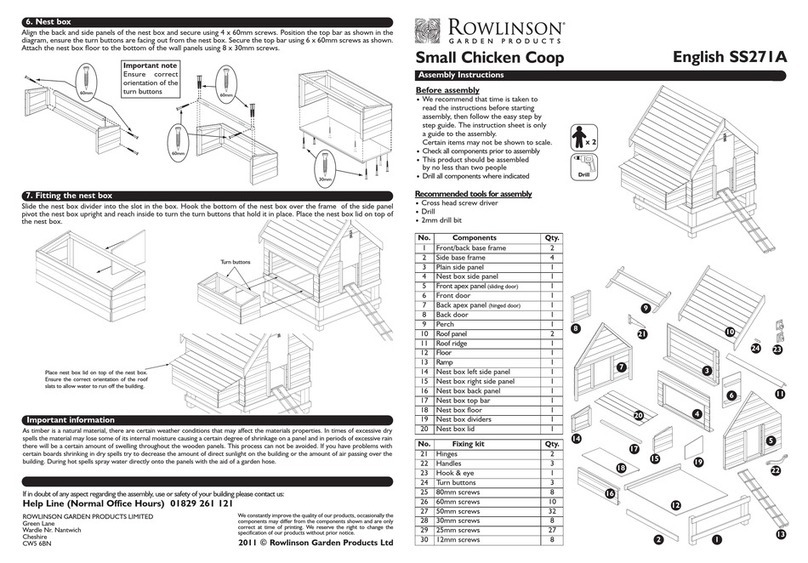

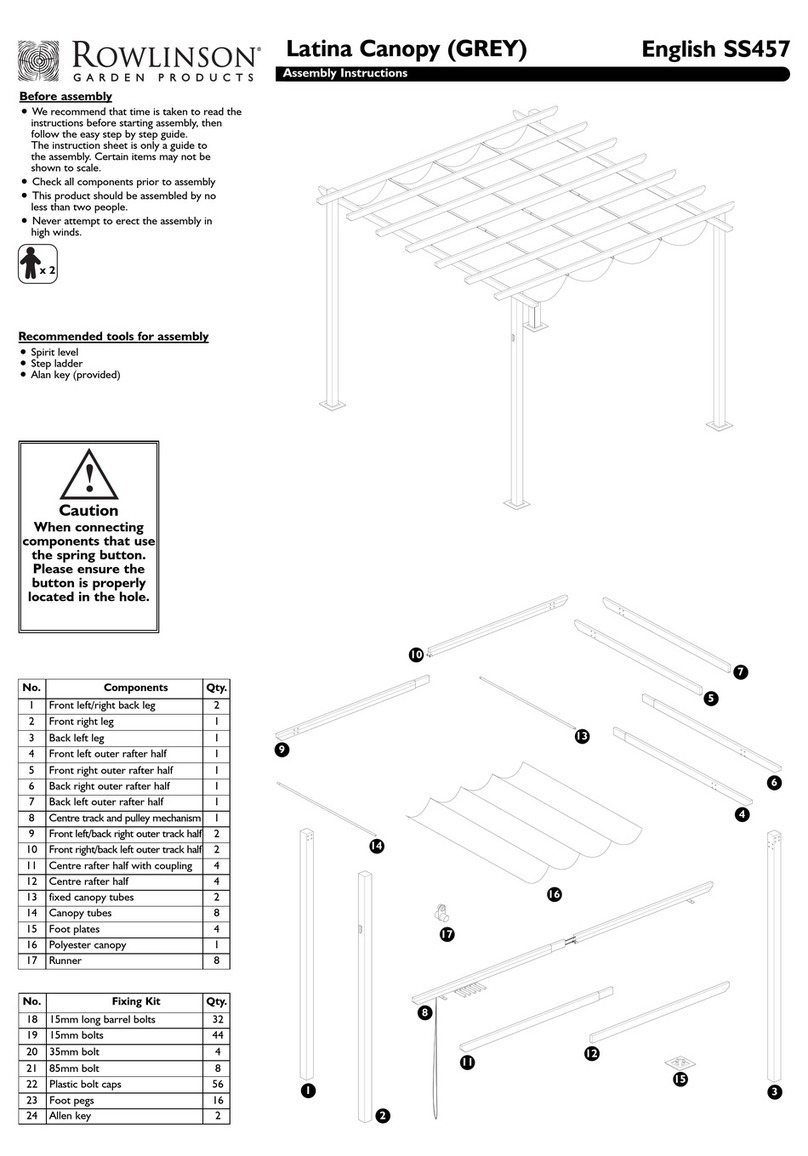

12. Latch door handle

Position the Latch door handle about half way up the door as shown in diagram. Mark the position of the holes on the door. Remove the latch and draw two lines connecting

opposite corners, drill a 12mm diameter hole where the two lines cross. Put the latch bar in the hole on the back of the latch, then reposition the latch (putting the bar

through the drilled hole) and attach using 4 x 19mm black screws. On the other side of the door fit the inside door handle to the bar and then using 4 x 19mm black screws

attach the handle to the door. On the front of the other door position the latch holder so that it holds the latch horizontal. Once in position attach to the door with 2 x

19mm black screws. With the doors shut, drop the lower tower bolt and mark where it touches the floor. Drill a 12mm hole in the floor for the bolt to fit in.

25mm

25mm

19mm

19mm

Drill 19mm

Drill

12mm diameter hole

Position the latch

door handle about

half way up the door

and mark the screw

holes.

12mm diameter hole

Important Note

It may be necessary to

shorten the latch bar to

60mm.

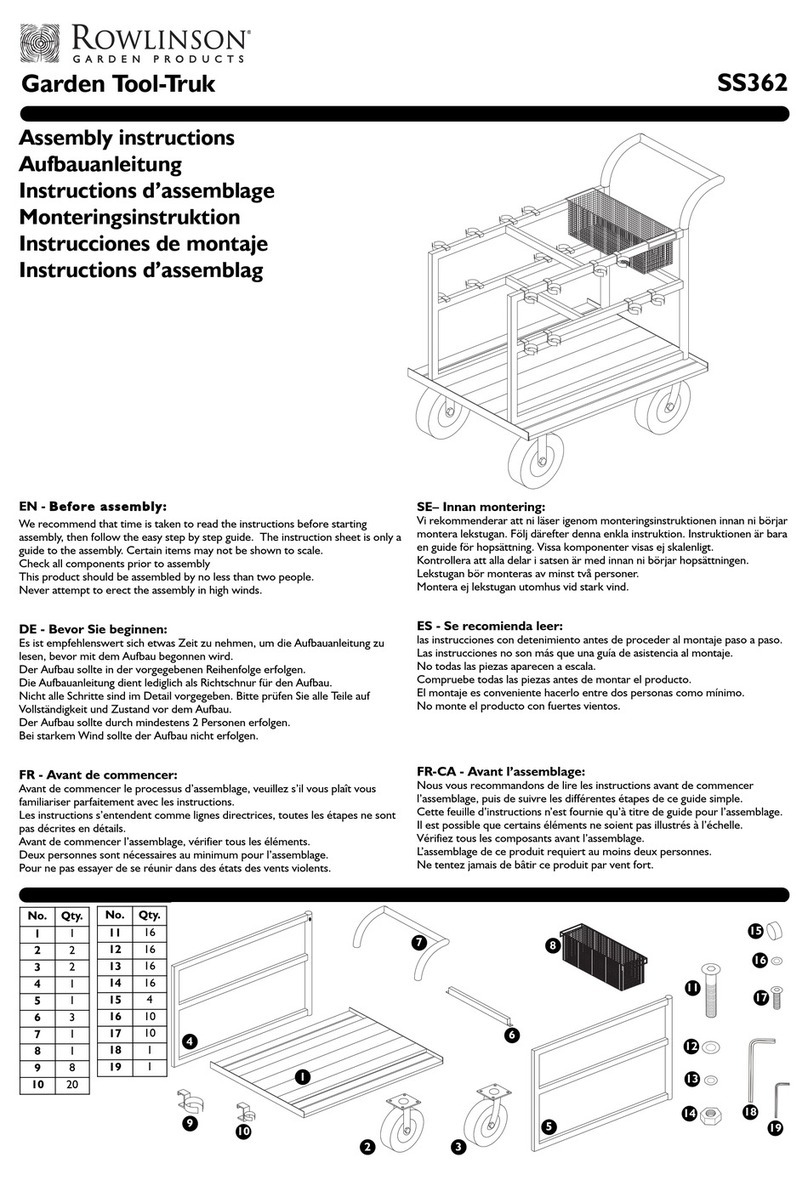

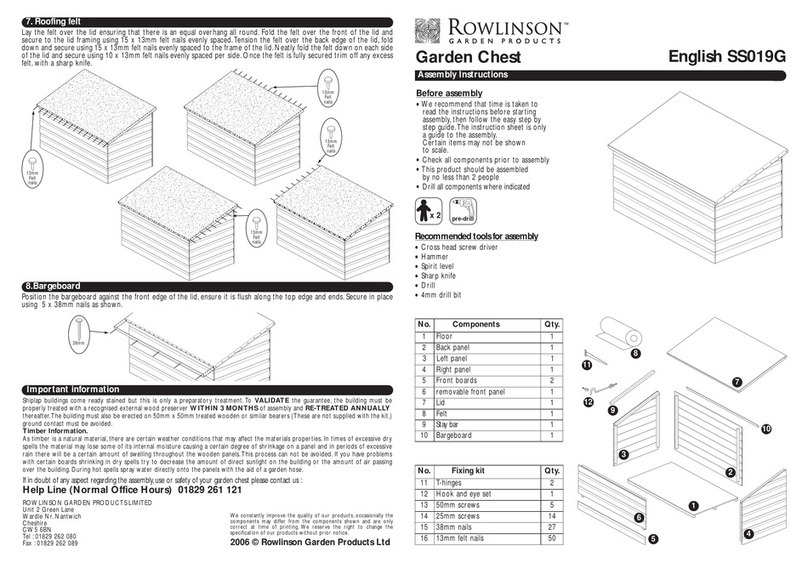

Important information

Shiplap buildings come ready stained but this is only a preparatory treatment. To VALIDATE the guarantee, the building must be properly treated with a recognised

external wood preserver WITHIN 3 MONTHS of assembly and RE-TREATED ANNUALLY thereafter. The building must also be erected on 50mm x 50mm treated

wooden or similar bearers (These are not supplied with the kit.) Ground contact must be avoided.

Timber Information.

As timber is a natural material, there are certain weather conditions that may affect the materials properties. In times of excessive dry spells the material may lose some

of its internal moisture causing a certain degree of shrinkage on a panel and in periods of excessive rain there will be a certain amount of swelling throughout the wooden

panels. This process can not be avoided. If you have problems with certain boards shrinking in dry spells try to decrease the amount of direct sunlight on the building or

the amount of air passing over the building. During hot spells spray water directly onto the panels with the aid of a garden hose.

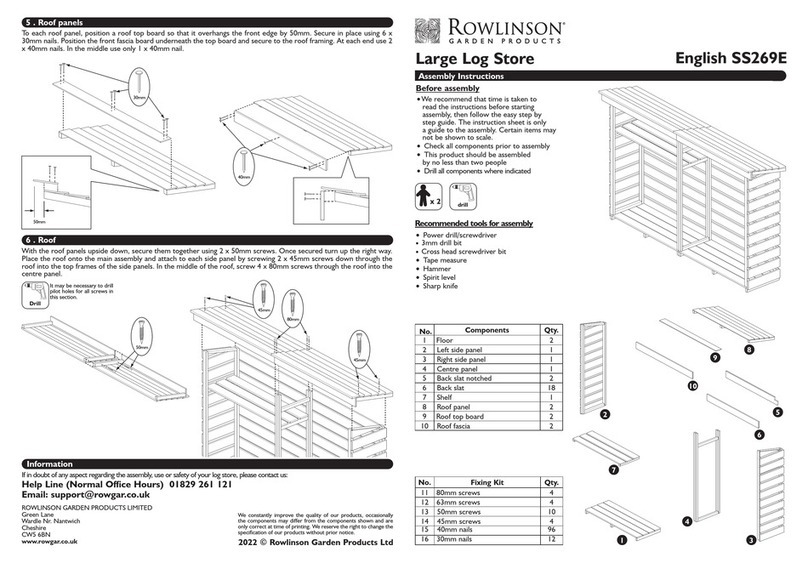

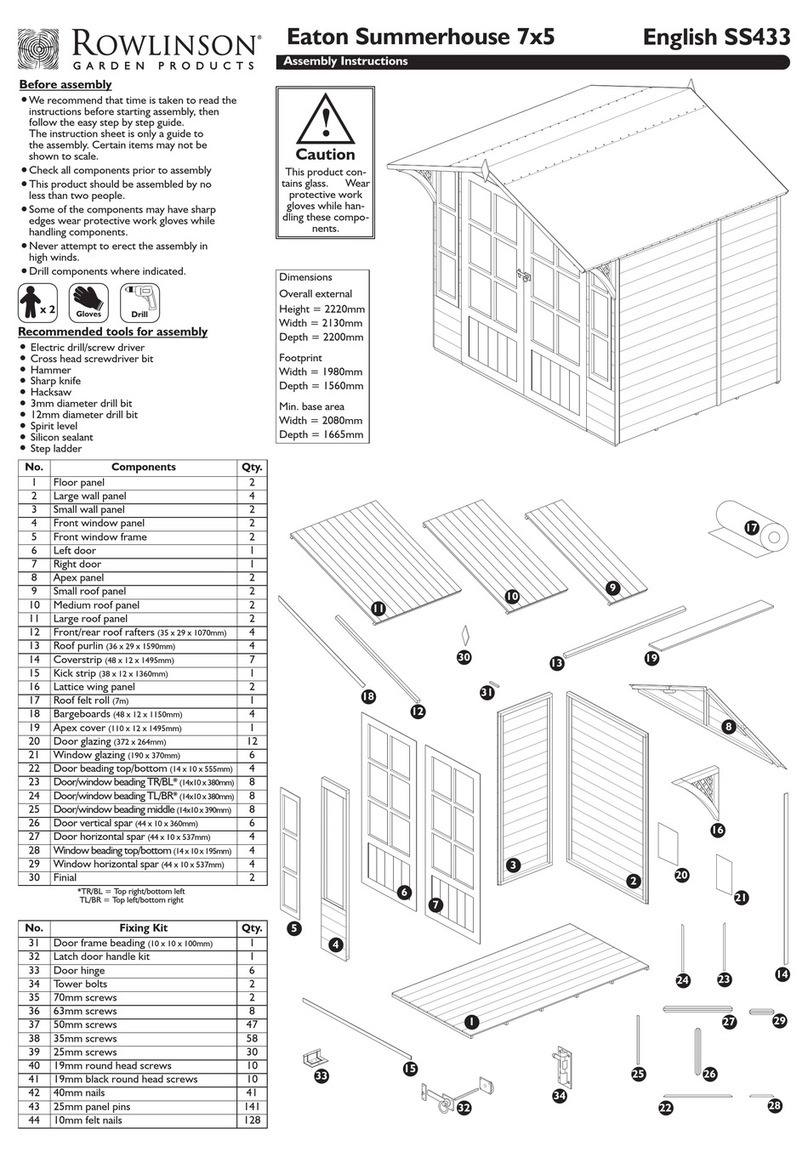

10. Coverstrips, bargeboards and finials

Fit a Coverstrips into each corner, attach using 3 x 40mm nails per strip. The remaining three are used to cover the panel joins, one on each side and the back, attach using

3 x 40mm nails per strip. Attach bargeboards at the front so that the top edge is flush with the roof line and the two boards meet evenly in the middle secure using

3 x 40mm nails per board. Attach a finial centrally over the join between the two bargeboards using 2 x 40mm nails. Fit the remaining bargeboards and finial to the back

of the building in the same way. Fit the kick strip to the bottom of the door opening using 4 x 40mm nails.

40mm

40mm

40mm

40mm

40mm

40mm

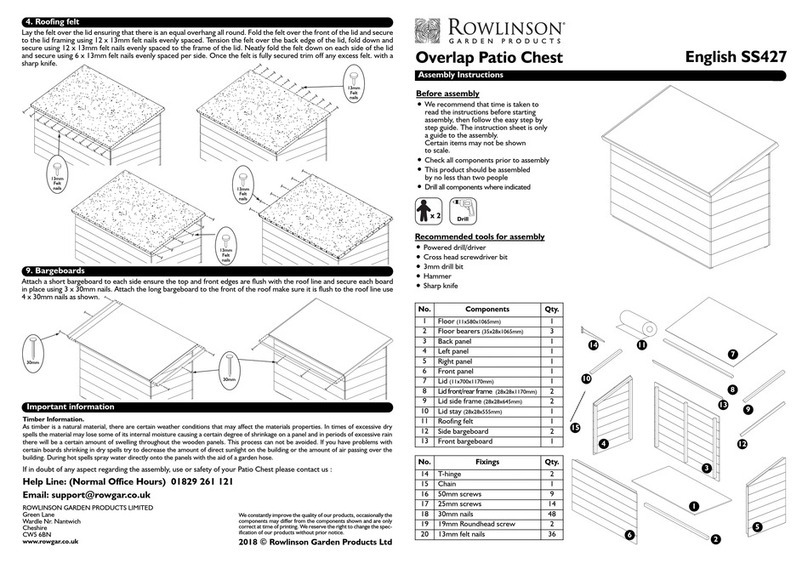

11. Hanging the doors

Fit three hinges to the long rebated edge of each door. Position them 150mm from the ends and one centrally between the other two. Attach the small tab of each hinge

using 2 x 25mm screws. Open the hinges and fit them around the door frame, adjust the door to the correct height and fix the hinges to the door frame using 3 x 25mm

screws per hinge. Attach the tower bolts to the inside of the left door as shown using 4 x 19mm round head screws per bolt.

2015 © Rowlinson Garden Products Ltd

We constantly improve the quality of our products,

occasionally the components may differ from the

components shown and are only correct at time of

printing. We reserve the right to change the

specification of our products without prior notice.

If in doubt of any aspect regarding the assembly, use or safety of your summerhouse please contact us :

Help Line: (Normal Office Hours) 01829 261 121

Email: support@rowgar.co.uk

ROWLINSON GARDEN PRODUCTS LIMITED

Green Lane

Wardle Nr. Nantwich

Cheshire

CW5 6BN

www.rowgar.co.uk