www.hitchcocksmotorcycles.com

Page

JO

Royal Enfield

"interceptor"

750

Series

11

Workshop Manual

21. Tappet Adjustment

The

tappet clearance

is

adjusted by means

of

a

screw in the

outer

end

of

the rocker. Access to the

adjusting screws

is

obtained

by removing the

covers

of

the rocker boxes.

The

correct clearances

are:-

Inlet .006 m

.,

Exhaust

.007 in.

These figures are for a

COLD

engine.

To

adjust

the clearance, loosei'i the

locknut

beneath the rocker

arm,

turn

the screw

and

re-

tighten the locknut.

The

adjustment

of

each valve should be made

with the corresponding valve in the

other

cylinder

fully open. This ensures

that

the

tappet

is

on

the

neutral position

of

the cam.

If

the heads

of

the adjusting screws are worn

they should be replaced.

22. Remornl

of

the

Camshafts

Remo

ve the timing cover (Subsection 19).

Remove the timing

chain

(Subsection 39).

Remove the rocker box covers

and

screw the

rocker

adjusting screws right back.

Unscrew the three screws holding each

of

the

timing side camshaft bearings. A hole

is

provided

in

the

camshaft

sprockets

and

this

can

be aligned

with each screw in

turn

, for access with a hexagon

wrench.

The

screws can be fully

undone

but

will

remain captive in the

cast

aluminium bearing.

Before removing

the

camshafts it

is

necessa1y

to

prevent

the tappets falling

through

their guides

when the shafts are

no

longer

holding

them up.

If

this

happens,

the

push

rods will come

out

of

engagement with the

rocker

arms

and make re-

pl;ctment

difficult. This can be prevented by

placing the

motor

cycle

on

its left side. With the

machine in this position,

rotate

the

camshaft

until

the

timing

marks

on

the

sprockets are

pointing

at

2

o'clock

for the inlet

and

I o'clock for the exhaust

when they

can

be

withdrawn

upwards complete

with sprockets

and

bearings.

If

the

machine has to

be moved before the shafts are replaced, it

is

essential

that

something

is

put

into

the

camshaft

tunnels to keep the tappets in place.

If

it

is

necessary to remove the sprockets from

the camshafts see Subsection 41.

23. Ignition Timing

The

contact

breakers are accessible after re-

moving the small oval cover. Owing to the provision

of

automatic

ignition advance, the

contact

breaker

is

always fully retarded when the engine

is

at

rest

or

is

being

turned

over slowly.

The

advance mechan-

ism

is

situated behind the

contact

breaker

and

gives a range

of

appro

ximately

12

° on the half-

speed shaft, corresponding to 24°

on

the engine

shaft.

The

optimum

ignition timing

is

32

° advance,

(.355 in. before

T.D.C.)

, so

that

in the fully

retarded

position thecontact points must openwhen the piston

is

8°

or

.023

in

. before T.D.C.

To

obtain

maximum performance

and

avoid

possible damage to the engine, it

is

vitally

important

that

the ignition timing

is

set accurately

and

also

identical

on

both cylinders. It

is

easier

to

obtain

the necessary accuracy

by

tin1ing with the ignition

cam in the advanced position

and,

to

hold

the

cam

in this position, a special recessed

washer

is

included in the tool kit.

As a further aid to ignition timing, an indicator

has been incorporated to show

the

correct position

of

the piston when the points are

just

beginning to

open

. Inside the primary chaincase, a line engraved

on

the

alternator

rotor

lines

up

with a second line

engraved

on

a fixed plate when the pistons

are

32

c

before T.D.C. These lines are visible after removing

the large screwed plug situated

towards

the

front

end

of

the chaincase.

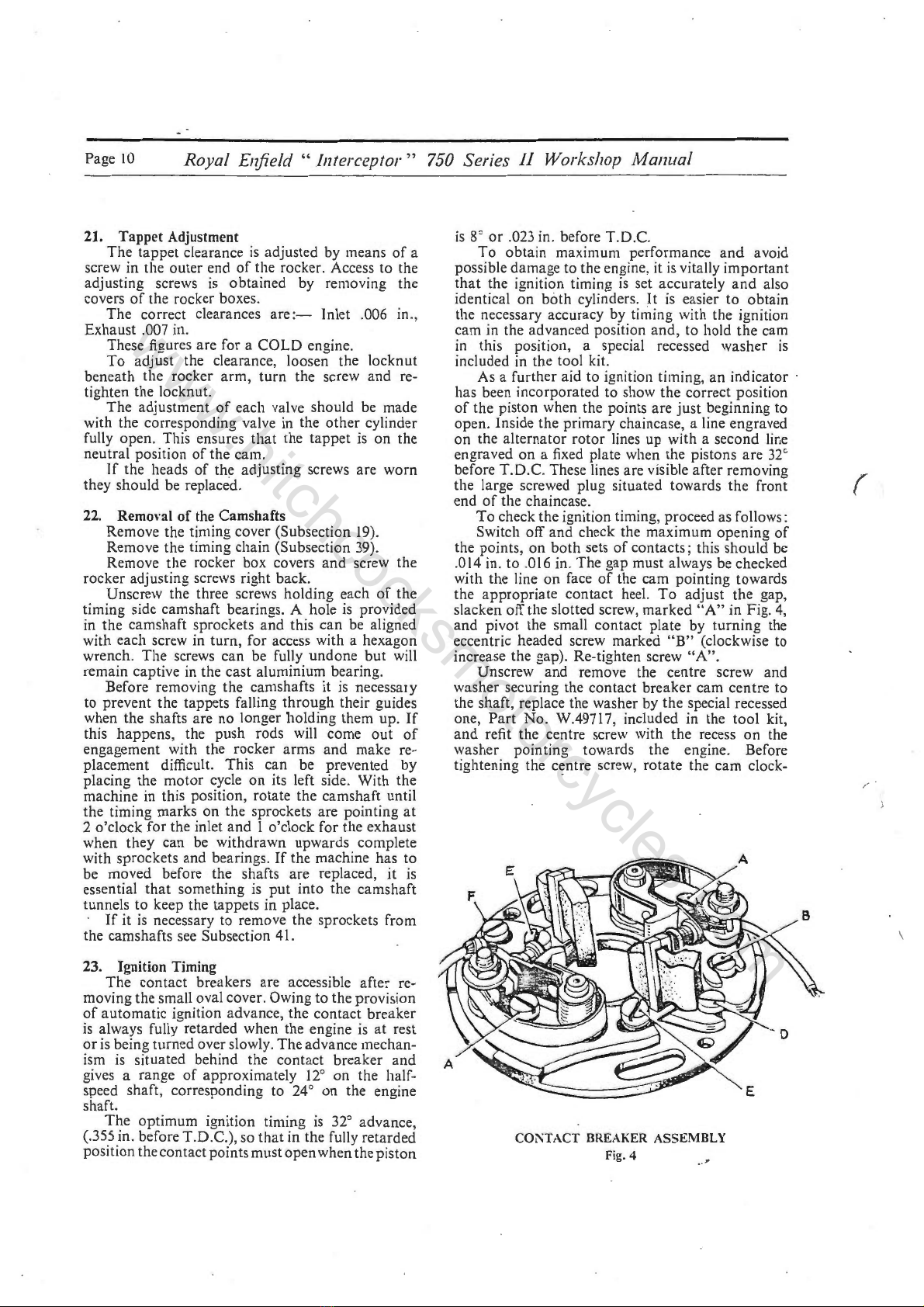

To

check the ignition timing, proceed as follows :

Switch off

and

check the

maximum

opening

of

the points, on

both

sets

of

contacts;

this

should

be

.014 in. to .016 in.

The

gap must always be checked

with the line

on

face

of

the earn

pointing

towards

the

appropriate

contact

heel.

To

adjust

the

gap,

slacken off the slotted screw,

marked

"A"

in Fig.

4,

and

pivot

the small

contact

plate

by

turning

the

eccentric headed screw marked

"B

" (clockwise to

increase the gap). Re-tighten screw

"A"

.

Unscrew

and

remove the centre screw and

washer

securing the

contact

breaker

cam centre to

the

shaft

, replace the washer by

the

special recessed

one,

Part

No

. W.49717, included

in

the

tool

kit,

and

refit the centre screw with

the

recess

on

the

washer pointing towards the engine. Before

tightening the centre screw,

rotate

the

cam

clock-

COi\TACT

BREAKER

ASSEMBLY

Fig. 4

r

\