MECHANICAL MAINTENANCE:

It is extremely important that your bicycle is checked and serviced at regular intervals to

ensure its reliability and especially that it is safe to ride.

Cleaning and lubrication also forms an important tool in the proper maintenance of your

Bicycle and this is covered in more detail immediately after this section.

The following checks are suggested:

Before your ride –check:

When you are riding, please use a bicycle helmet for your safety.

Set reflectors on your bicycle for possible national legal requirements when you ride on the public

road.

The maximum total weight is 100kg. (bicycle+rider+luggage)

Wheels are tightly secured.

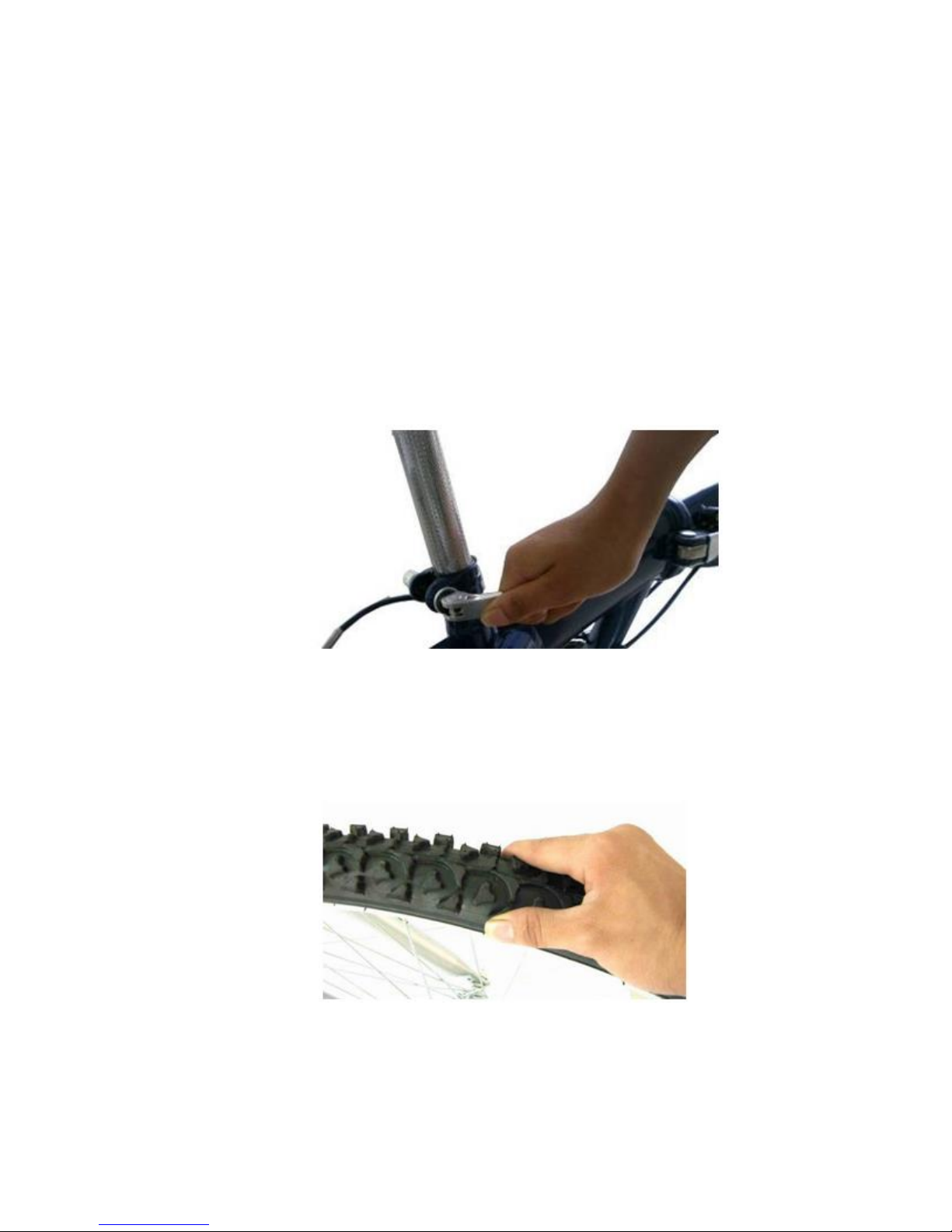

Tyres are inflated to correct pressure (indicated on side-wall of tyre). Also check condition of tyres for

cuts etc. (Note: It is a good idea to carry a puncture repair kit or spare inner tube, tyre levers and pump

with you).

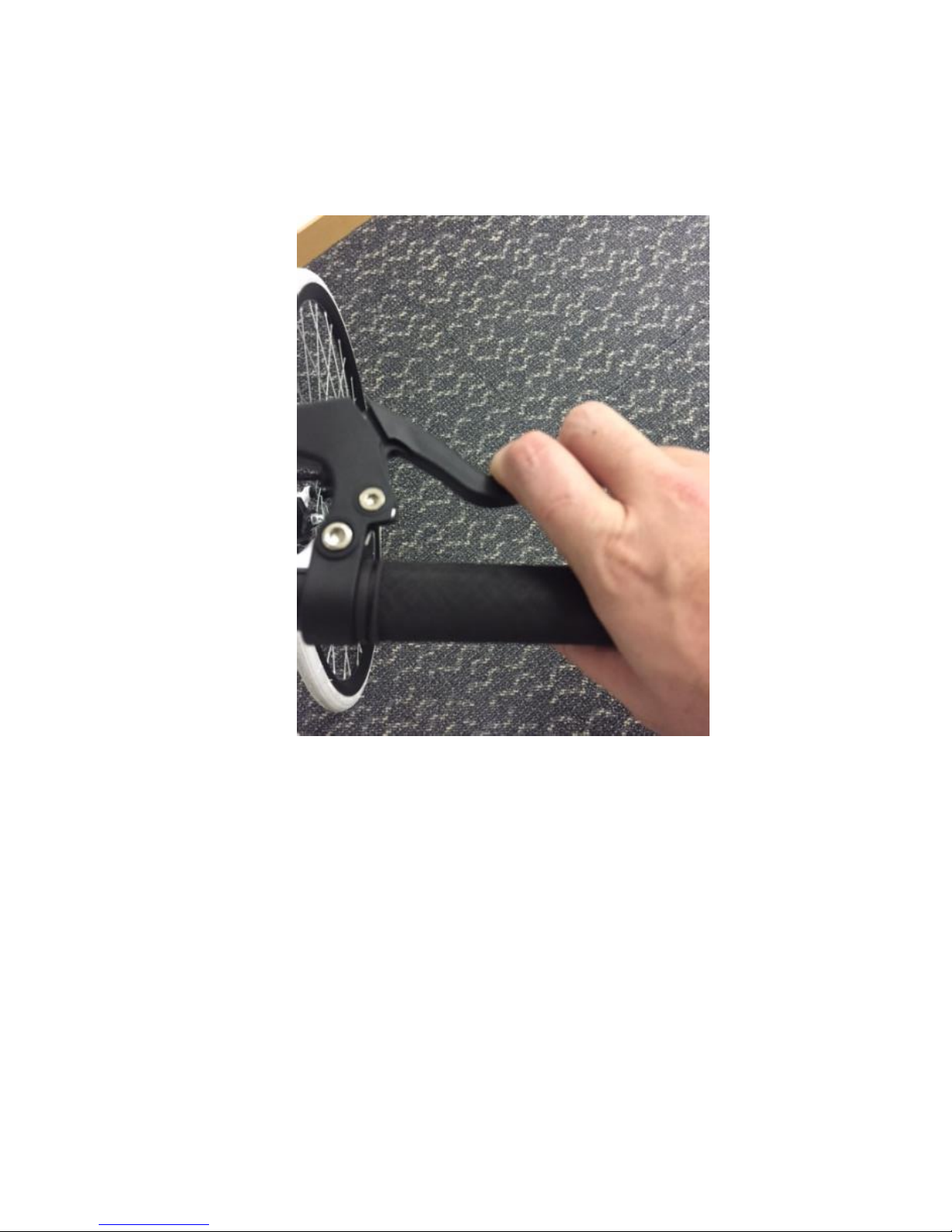

Handlebar, stem and headset locknut are tight and that the steering turns smoothly.

Squeeze the brake levers to ensure sufficient pressure can be applied without the lever touching the

handlebars. Also ensure brake blocks are aligned correctly with the rim and the blocks are not badly

worn.

Brake cables are not frayed at the end.

Gears operate correctly and smoothly.

Wheels are running true by spinning them. You can also check that mudguards, if fitted, are correctly

adjusted at this time.

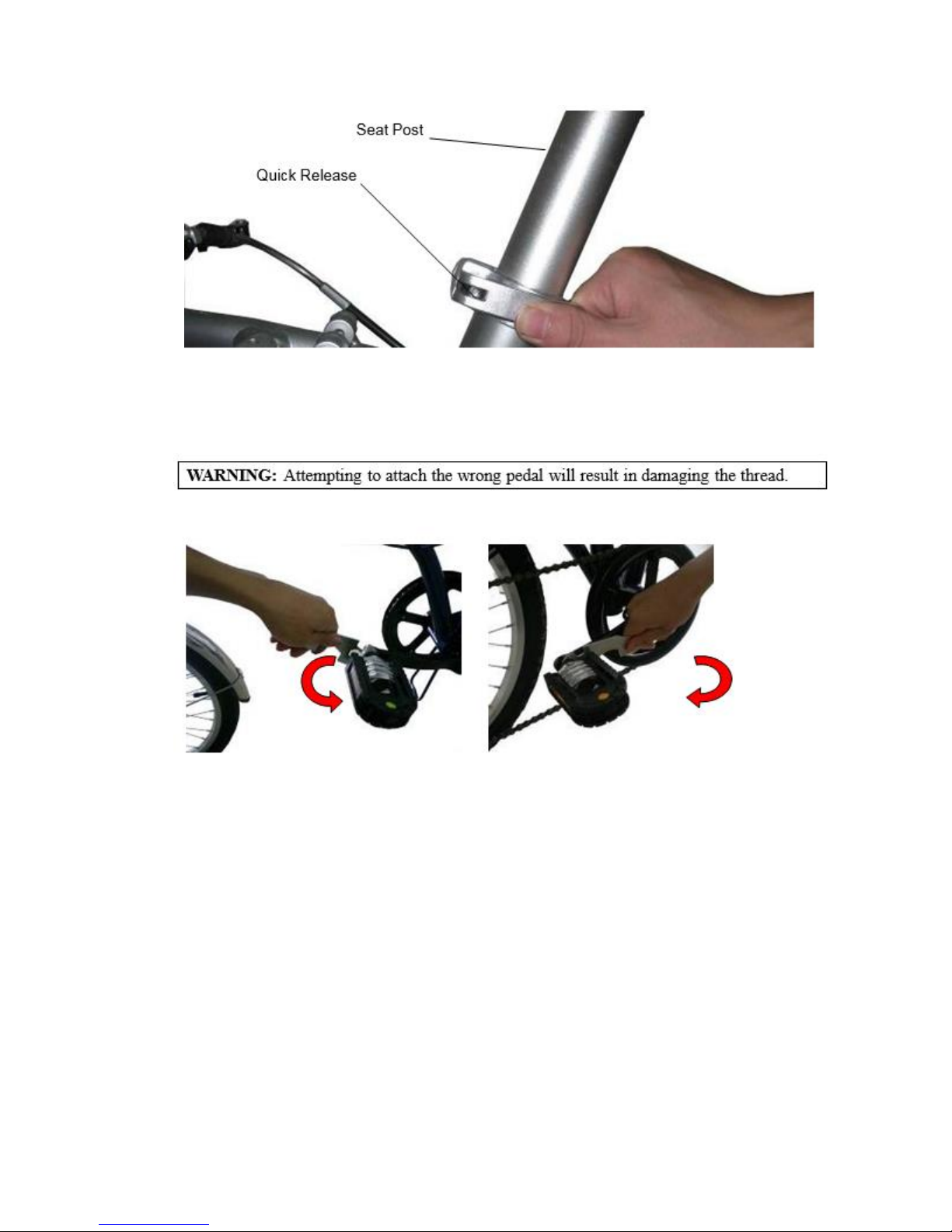

The height of the seat can be adjusted from 650mm to 1020mm. The vertical distance from the ground

to the top of the seat surface, measured with the seat in a horizontal Position and with the seat-pillar

set to the minimum insertion depth.

After long or hard rides or at least every month of regular use –check the above as well as the following:

Clean, degrease and lubricate your bicycle.

Crank, bottom bracket fittings and pedals are tight.

Tyre wear and general condition for cuts, glass, thorn etc.

Spokes are not loose or broken. These need to be attended to before the bike can be ridden again and

you would probably need to get these done at bicycle shop.

Hubs are running smoothly.

Tyres are free from imbedded objects such as thorns, glass or nails.