V+ Series

V608CH+ OPERATING INSTRUCTIONS

Before using this V608CH+, be sure to read this OPERATING

INSTRUCTIONS thoroughly to ensure proper operation.

Make sure that the delivered unit conforms to your requirement,

and also check for any missing or damaged parts.

Instruction manuals as below are available upon request from your

nearest sales office.

Accessories furnished with this unit:

[Accessories]

V608CH+ OPERATING INSTRUCTIONS 1 copy

*ecp 1pmalC elbaC

Neck Strap 1 pce*

2swercS pcs (M3 x 10) *

* About mounting procedure, refer to "Specifications for V608CH+."

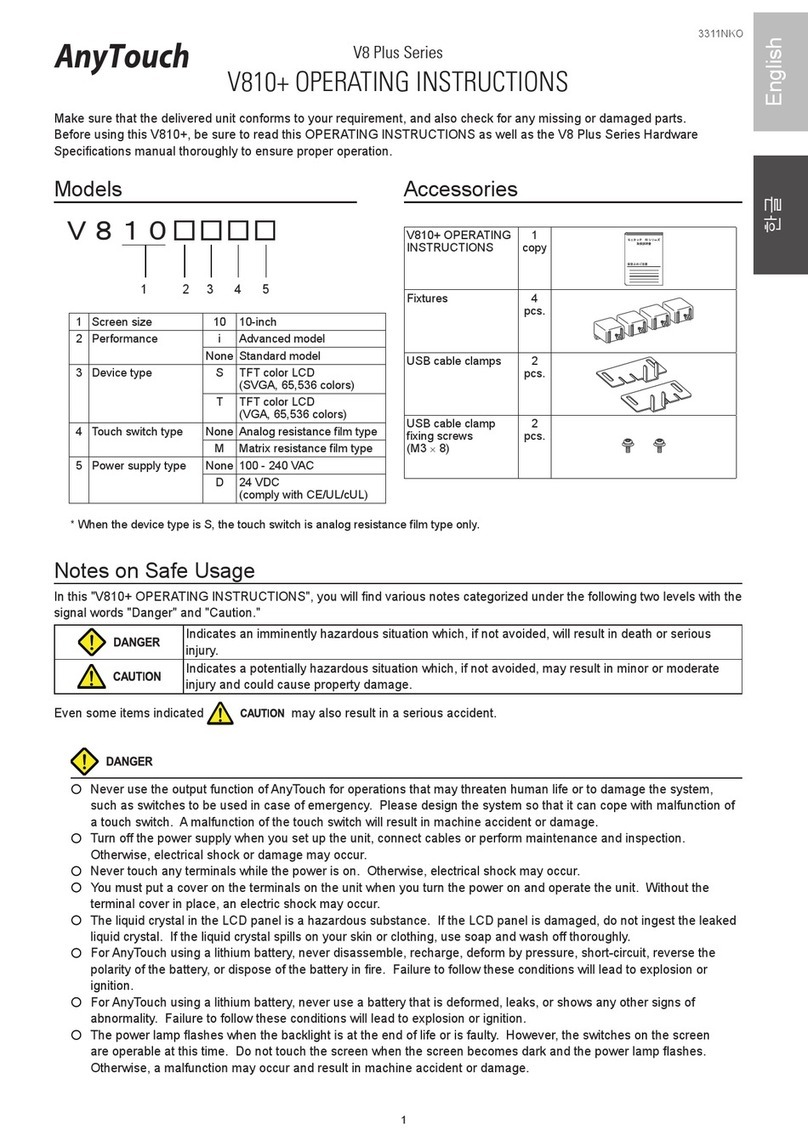

Models

Comply with CE/UL/cUL

106

POWER

SW1

SW4

SW3

SW2

F3

F2

F1

F7

F6

F5

F4

SYSTEM

ENB

47

24

259

232

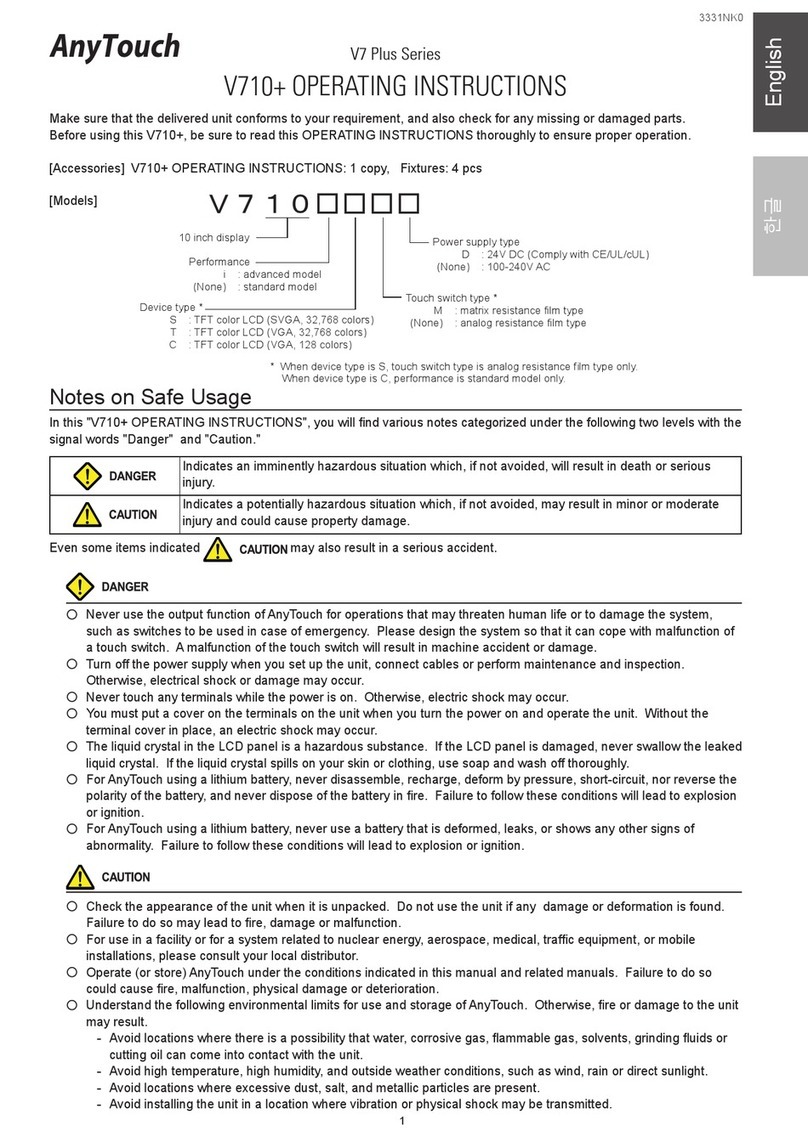

Top View

Front View

Side View

Bottom View

Rear View

unit : mm

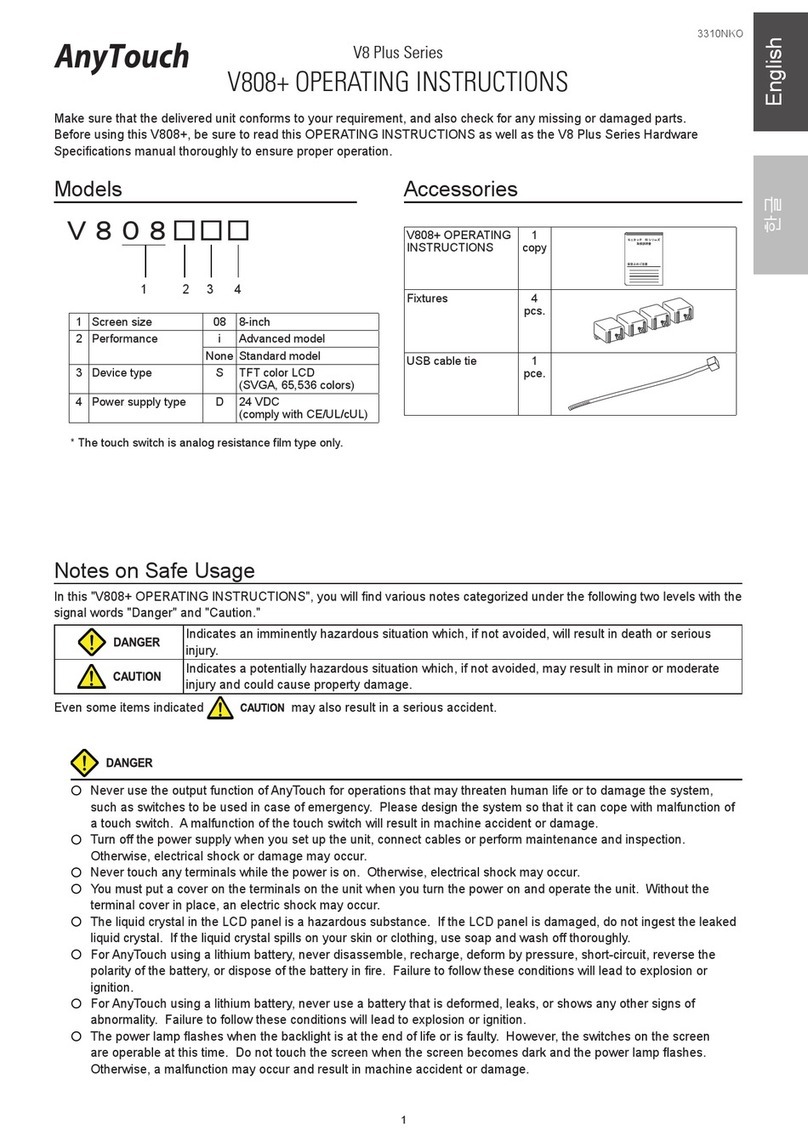

Names of Components

Front Side

1. Deadman switch / 3-position switch

2. Emergency Stop switch

3. ENB lamp

4. Function keys

5. Output (to outside) switches

6. Display

7. Power lamp

8. Key switch (option)

TB1 MJ1

SW1

POWER

SW1

SW4

SW3

SW2

F3

F2

F1

F7

F6

F5

F4

SYSTEM

ENB

9. Terminals for PLC communication, power

supply and output (to outside)

10. MJ1: for data transfer

11. SW1: Terminal resistance(upper:on)

12. Mounting holes for cable clamp and

neck strap

13. Mounting holes for wall-mounting fixture

(V6H-WF+:option)

14. Connector for battery (V6H-RB+:option)

maintaining the data of built-in clock

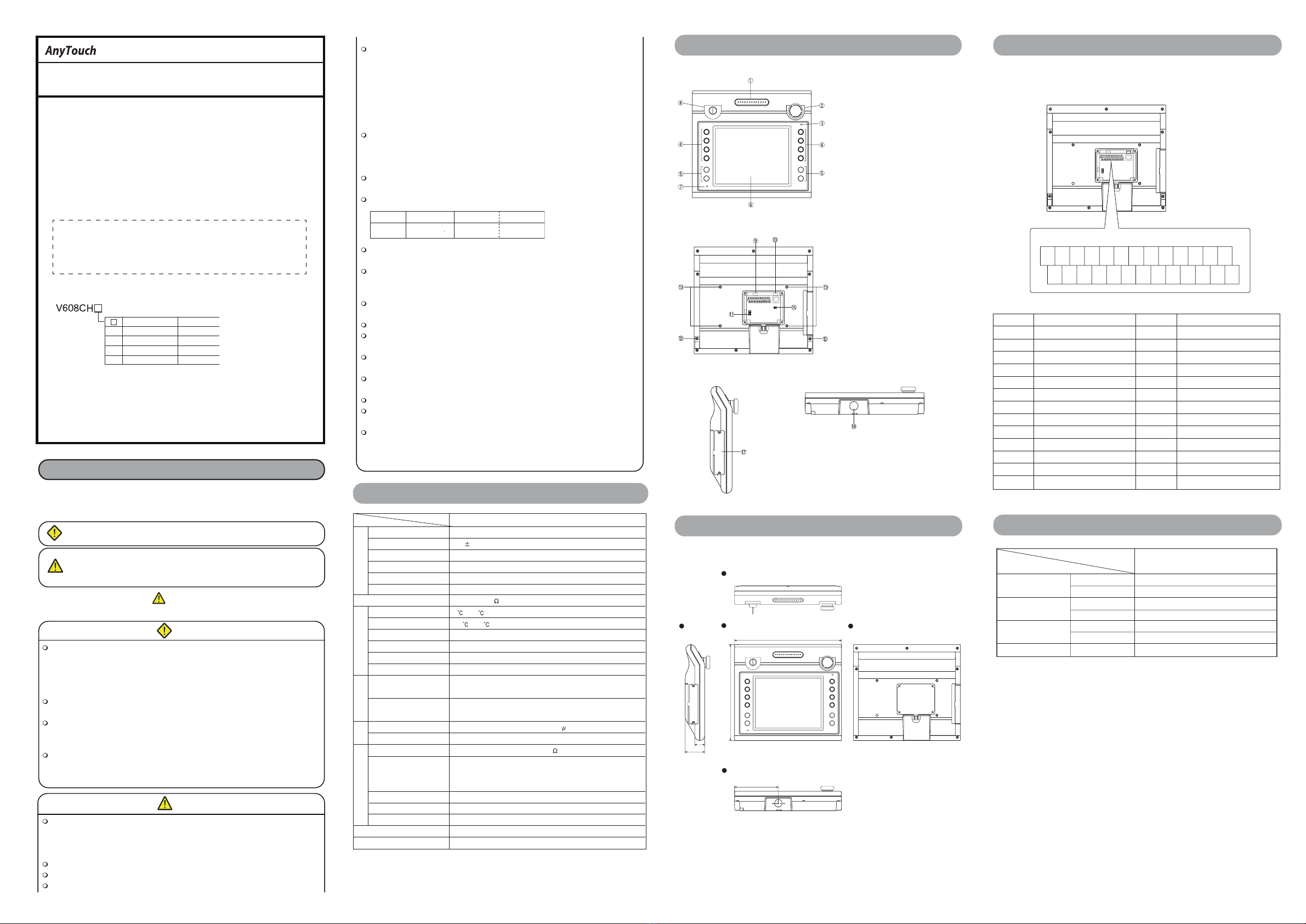

Specifications

Power SupplyPhysical Environment

Mechanical

Working

Conditions

Electrical

Working

Conditions

Mounting Conditions

Item Type

Rated Voltage

Permissible Range of Voltage

Permissible Momentary Power Failure

Demand

Rushed Electric Current

With-stand voltage

Insulation Resistance

Ambient Temperature

Storage Ambient Temperature

Ambient Humidity

Dust

Solvent Resistance

Corrosive Gas

Vibration Resistance

Shock Resistance

Noise Resistance

Static Electricity Discharge Resistance

Grounding

Structure

V608CH+

Protection structure: front panel complies with IP65

(except V608CH2+/V608CH3+)

Form: in a body

Mounting procedure: hand-held, wall-mounted, tabletop

500V DC, 10M or more

0 ~+50

-10 ~+60

85% RH or less (without dew condensation)

No conductive dust

No cutting oil or no organic solvent to cling to the unit

No corrosive gas

Vibration frequency: 10~150Hz, Acceleration: 9.8m/s (1.0G)

3 directions of X, Y and Z: one hour

Pulse shape: Sine half wave,

Peak acceleration: 147m/s (15G), 3 directions of X, Y and Z: six times

Noise voltage: 1000Vp-p, noise width: 1 s

Contac: 6kV , Air: 8kV

Grounding resistance: less than 100

Cooling naturally

Approx. 1.2kg

259 X 232 X 47 (except the size of Emergency Stop switch)

the Munsell color system N-2.0 (BLACK)

PC/ABS

24V DC

24V 10% DC

within 10ms (24VDC)

20W or less

13A, 2ms

DC external terminals to FG : 500V AC per min.

(mm)

2

2

Cooling System

Weight

Dimensions W

X

H

X

D

Case Color

Material

Notes on Safe Usage

In this "V608CH+ OPERATING INSTRUCTIONS," you will find

various notes categorized under the following two levels with the

signal words "Danger" and "Caution."

Indicates an imminently hazardous situation which, if

not avoided, will result in death or serious injury.

Indicates a potentially hazardous situation which, if

not avoided, may result in minor or moderate injury

and could cause property damage.

DANGER

CAUTION

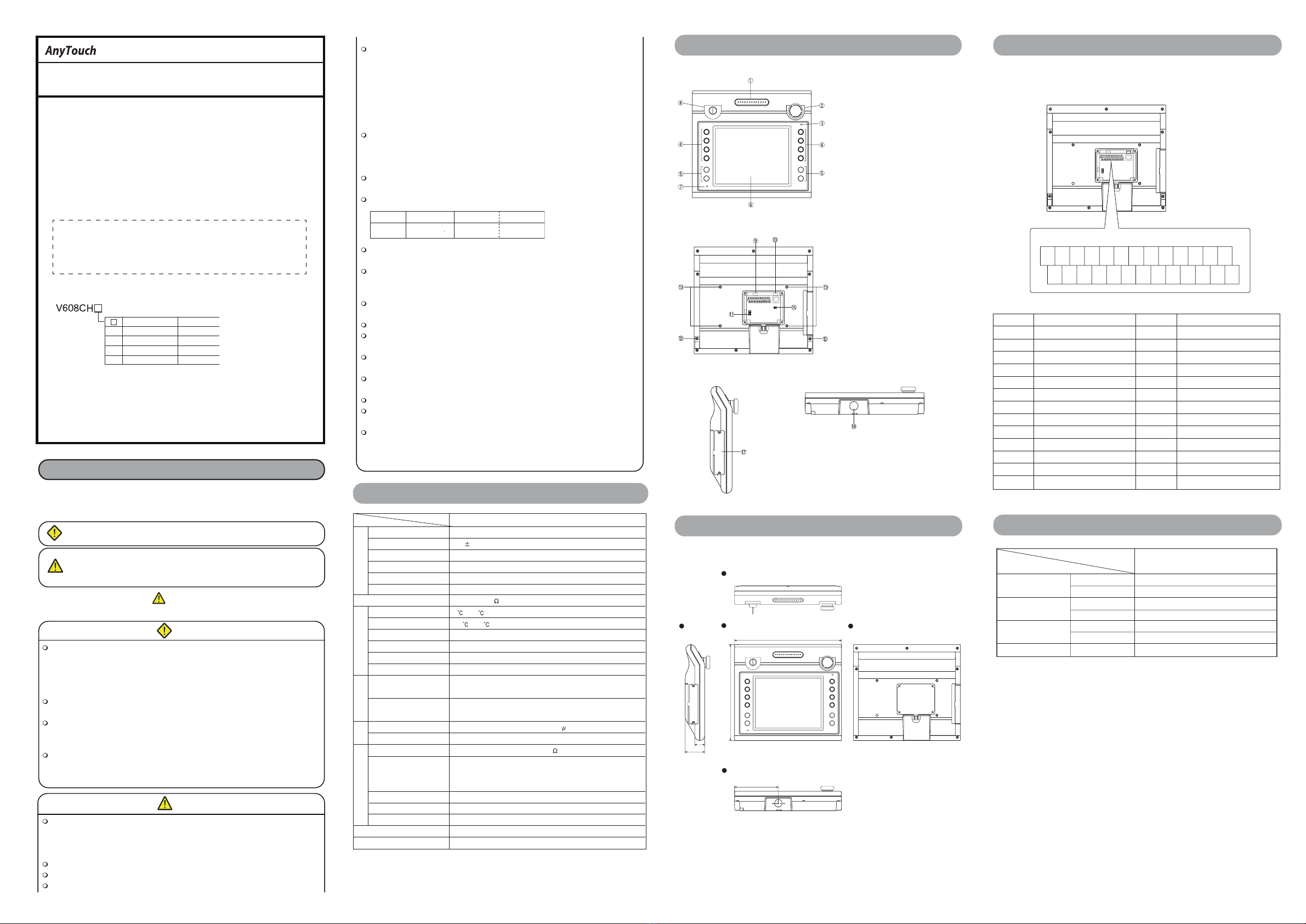

TB1

This terminal block is used for communication with PLC, power supply

and output to outside.

The pin arrangement is as follows:

Dimensions Other Specifications

Screw Size

M2

Torque

0.22 - 0.25

N m

Solid wire

0.14 - 1.5mm2

Stranded wire

0.14 - 1.0mm2

Rear Side

wire, inspect, and maintain the product.

Maintain the following conditions in order to avoid fire or trouble.

-Do not let the unit come in contact with water, corrosive gas, flammable gas,

solvents, grinding fluids or cutting oil.

-Never let the unit be exposed to high temperature, high humidity, and other

outside weather conditions.

-Do not allow the unit to be exposed to excessive dust, salt, and metallic

particles.

-Do not allow the unit to be shaken or hit by other objects.

Connect the cables correctly to the terminals of AnyTouch in accordance with

the specified voltage and wattage. Over-voltage, over-wattage and the incorrect

cable connection could cause the unit to be damaged physically or functionally

and also could result in fire.

Equipment must be correctly mounted so that the main terminal will not

inadvertently be touched during an application.

Tighten terminal block screws with the following torques.

Prevent any conductive particles from entering into AnyTouch. The conductive

particles could cause fire, trouble, or malfunction of the unit.

Never bundle input/output cables with high-voltage and large-current cables such

as power supply cables. Keep input/output cables at least 200mm away from

power supply cables in order to avoid malfunction caused by noise.

This equipment must be earthed. Ground FG terminal which must be for the unit.

The level of grounding resistance is less than 100Ω.

Do not press the keypad switches with sharp-pointed tools.

Application of thinner may discolor AnyTouch. Use alcohol or benzine available

commercially for cleaning.

RS Automation Co., Ltd. is not responsible for an unauthorized person who may

fix, disassemble, or reconstruct any unit.

As for the use in the facilities related to nuclear energy or in the facilities of

official importance, please consult with our distributer about it.

Follow the regulations of industrial wastes when the device is to be discarded.

Do not press two or more points on a screen at the same time. This may active

a switch located between the points pressed.

Avoid display the same patterns for hours.

It may cause afterimages due to the property of LCD display. If you use the

fixed patterns for hours, use the auto-OFF function of the backlight.

Deadman Switch Key Switch

0 Momentary None

1 Momentary Provided

2 3-position None

3 3-position Provided

Side Bottom

15. CF card interface

16. Mounting holes for communication cable

TB1 MJ1

SW1

TxD RxD +SD -SD +RTS -RTS D01 D03 COM- EMG1 EMG2 +24V 0V

RTS CTS SG +RD -RD +CTS -CTS D02 D04

E_COM

KEY1 KEY2 FG

TB1

Signal

KEY2

TXD

RXD

SG

+24V

0V

+SD

-SD

+RTS

-RTS

Contents

Key switch 2

RS-232C send data

RS-232C recieve data

Signal ground

RS-485 send data (+)

RS-485 send data (-)

RS-485 control signal

RS-485 control signal

RTS

CTS

RS-232C control signal

RS-232C control signal

Power supply for V608CH+

0V

+CTS

-CTS

RS-485 control signal

RS-485 control signal

+RD

-RD

RS-485 recieve data (+)

RS-485 recieve data (-)

D01

D03

COM-

EMG1

EMG2

Output SW1

Output SW3

Output common

Emergency stop 1

Emergency stop 2

D02

D04

Output SW2

Output SW4

E_ COM

FG Frame ground

KEY1 Key switch 1

Emergency stop 1, 2 common

Signal Contents

V608CH+

Emergency Stop switch

Deadman switch

3-position switch

(option)

Key switch (option)

Item

Type

Push-lock type

Two B-contacts, single common

Momentary

Single A-contact

3-position

Single A-contact (double interrupting, slow action)

Single A-contact

Form

Contacts composition

Form

Contacts composition

Form

Contacts composition

Number of contacts

Even some items indicated "

CAUTION

" may also result in a serious

accident.

DANGER

Never use the input function of AnyTouch such as the touch switch (except

Emergency Stop switch) for an emergency switch because it could threaten a

human life or break a part of the unit.

Please design the system of the unit in order to respond to a malfunction of the

touch switch.

Never touch the terminals while the power supply is on, otherwise you will get an

electric shock.

Turn off the power supply when you set up the system, connect the cables,

maintaining or checking, otherwise you will get an electric shock or damage the

unit.

The liquid (liquid crystal) on the liquid crystal display is harmful. If it has been

damaged, it must not get into the mouth. If the skin or clothes are stained with

in, rinse them with soapy water.

CAUTION

Operate AnyTouch under the conditions indicated by OPERATING

INSTRUCTIONS or relevant manual.

If you do not set the conditions indicated by the manual for the unit, it could

cause fire, malfunction, physical damage or deterioration.

Do not use the one found damaged or deformed when unpacked.

AnyTouch has a glass screen. Never drop or subject the unit to strong impacts.

Only a qualified person with the necessary technical knowledge should install,

Publication

RS Automation Co., Ltd.

3341NKO