2

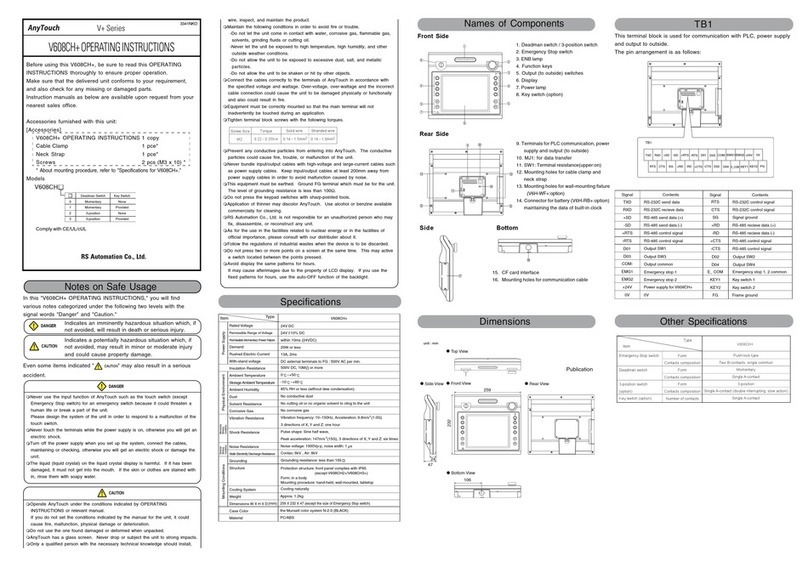

○Maintain the following conditions in order to avoid fire or trouble.

−Do not let the unit come in contact with water, corrosive gas, flammable gas, solvents, grinding fluids or cutting oil.

−Never let the unit be exposed to high temperature, high humidity, and other outside weather conditions.

−Do not allow the unit to be exposed to excessive dust, salt, and metallic particles.

−Do not allow the unit to be shaken or hit by other objects.

○Equipment must be correctly mounted so that the main terminal will not inadvertently be touched during an application.

Otherwise, an accident or electric shock may occur.

○Tighten mounting screws equally with torque: 0.3 to 0.5 N·m. Never fasten these screws too tightly, otherwise the cover

of AnyTouch may be deformed. Clamping these screws loose may cause drops, shortcircuits and malfunctions.

○Check periodically that terminal screws and mounting screws are firmly tightened. Loosened screws may result in fire

or malfunction.

○Tighten power supply input terminal screws with torque: 0.5 N·m. Improper tightening of screws may result in fire,

malfunction, or trouble.

○AnyTouch has a glass screen. Never drop or subject the unit to strong impacts. Otherwise, the screen may be

damaged.

○Connect the cables correctly to the terminals of AnyTouch in accordance with the specified voltage and wattage. Over-

voltage, over-wattage and the incorrect cable connection could cause the unit to be damaged physically or functionally

and also could result in fire.

○A power supply line of 24V DC for V606e+ has a varistor. Do not execute the insulation resistance test (500VM test)

and the withstand voltage test (500V AC) for the equipment. Or the equipment may be broken because of the on-board

varistor.

○This equipment must be earthed. Ground FG terminal which must be for the unit. Otherwise, electric shock or a fire

may occur.

○Prevent any conductive particles from entering into AnyTouch. The conductive particles could cause fire, trouble, or

malfunction of the unit.

○After wiring is finished, remove the paper used as a dust cover before starting to operate AnyTouch. Operation with the

cover attached may result in accident, fire, malfunction, or trouble.

○Do not attempt to repair disassemble or modify AnyTouch at your site. Ask RS Automation Co., Ltd. or the designated

contractor for repair.

○RS Automation Co., Ltd. is not responsible for an unauthorized person who may fix, disassemble, or reconstruct any

unit.

○Do not press the touchswitch with sharp-pointed tools. Doing so may damage the screen.

○Only a qualified person with the necessary technical knowledge should install, wire, inspect, and maintain the product.

○For AnyTouch using a lithium battery, handle the battery with care. The combustible materials such as lithium or

organic solvent contained in the battery may generate heat, explode, or catch fire, resulting in personal injury or fire.

Read related manuals carefully and handle the lithium battery correctly as instructed.

○AnyTouch V606e+ employs an analog resistance membrane switch. Do not press two or more points on a screen at

the same time. This may activate a switch located between the points pressed.

○Take safety precautions during such operations as setting change during running, forced output, start, and stop. Any

misoperation may cause unexpected machine motions, resulting in machine accident or damage.

○In facilities where a failure of AnyTouch could lead to accident threatening human life or other serious damage, be sure

that the facilities are equipped with adequate safeguards.

○Follow the regulations of industrial wastes when the device is to be discarded.

○Before touching AnyTouch, discharge static electricity from your body by touching grounded metal. Excessive static

electricity may cause malfunction or trouble.

○Prevent the static electricity from being charged on the sheet metal where AnyTouch is mounted to avoid malfunction

caused by noise.

○Never bundle input/output cables with high-voltage and large-current cables such as power supply cables. Keep input/

output cables at least 200 mm away from power supply cables in order to avoid malfunction caused by noise.

○When using AnyTouch under the circumstance where some equipments which may cause high-frequency noise are

operated, connecting the FG shielded cable both to AnyTouch and to the other equipment sides is recommended.

However, if the communication becomes unstable, try to connect the FG shielded cable either to AnyTouch or to the

other equipment side according to the circumstance.

○Do not use thinners for cleaning because they may discolor the AnyTouch surface. Use alcohol commercially available.

○A receiving error may occur on a device that is connected to AnyTouch such as a PLC or a temperature controller by

starting up both equipments at the same time. In such case, follow the instructions of such device's manuals to handle

the error.