Document Number 900-21806 Rev C 8

840-30586 KIT, ACCESSORIES, 6” CRAWLER

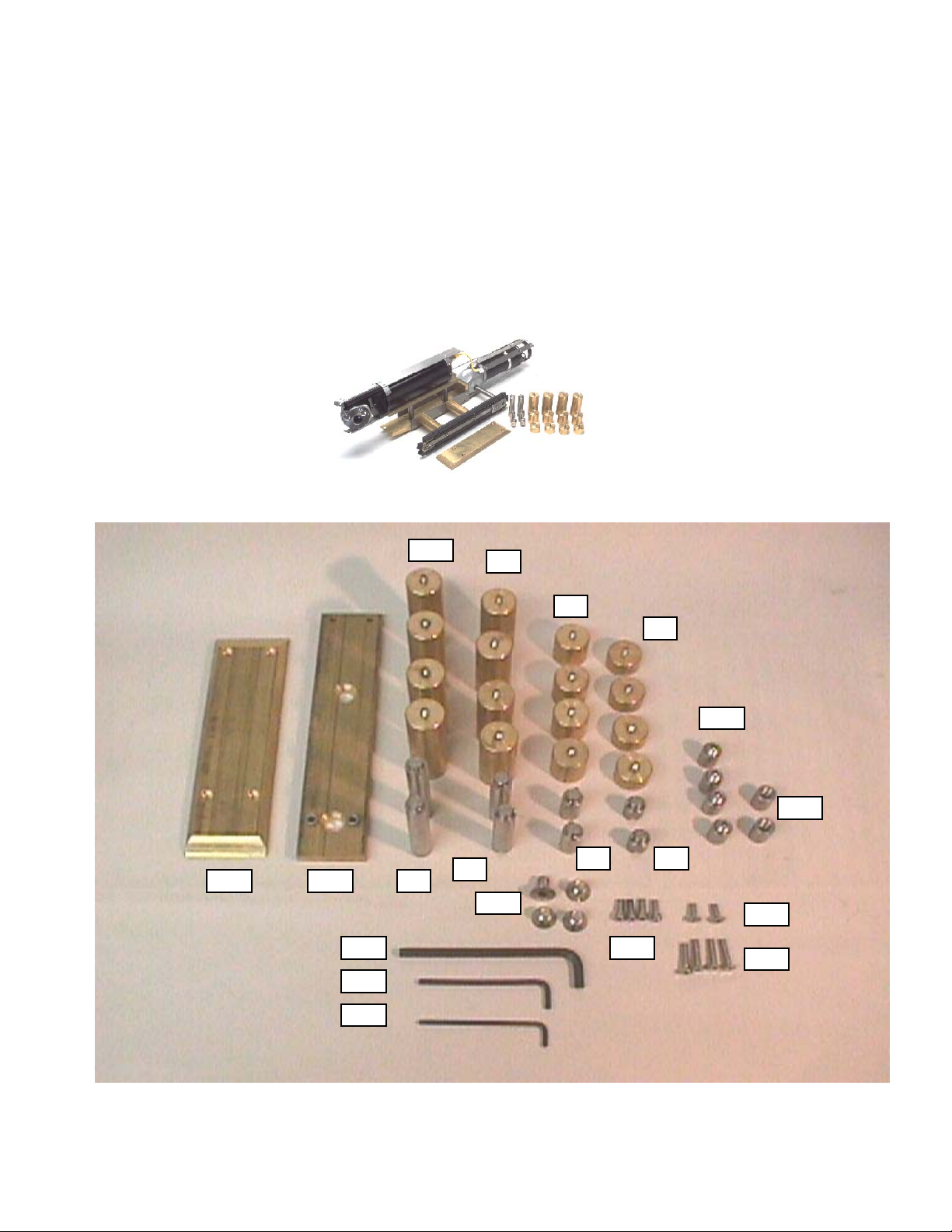

1701-30994 BOX, TOOL, PLASTIC, W/TRAY 1.0 EA.

2 706-30754 LABEL, KIT, ACCESSORIES, 6" CRAWLER 1.0 EA.

3867-30920 ASSY, COUPLING, EXTENSION, .87", CRAWLER 2.0 EA.

4867-30921 ASSY, COUPLING, EXTENSION, 1.50", CRAWLER 2.0 EA.

5867-31713 ASSY, COUPLING, EXTENSION, 2.37", CRAWLER 2.0 EA.

6867-30922 ASSY, COUPLING, EXTENSION, 3.18", CRAWLER 2.0 EA.

7867-30925 ASSY, SPACER, 87" LONG, EXTENSION SET, CRAWLER 4.0 EA.

8867-30926 ASSY, SPACER, 1.50" LONG, EXTENSION SET, CRAWLER 4.0 EA.

9867-30927 ASSY, SPACER, 3.18" LONG, EXTENSION SET, CRAWLER 4.0 EA.

20 800-17114 ASSY, SPACER, 1.0", M/L TRACTOR TREAD 4.0 EA.

21 402-17109 SPACER, MTG., 1.0"EXTENSION, ML TRACTOR TREAD 2.0 EA.

22 453-30916-23 PLATE, BALLAST, BOTTOM, 6" CRAWLER PLATED 1.0 EA.

23 867-3093 ASSY, PLATE, MTG., OE3 CAMERA, CRAWLER 1.0 EA.

24 301-12650 MSCR, FLT, HXS, 1/2-13X.75 SS 4.0 EA.

25 301-11005 MSCR, SHCS, 1/4-20X.62 SS 4.0 EA.

26 301-11360 MSCR, FLT, HXS, 1/4-20X1.25 SS 4.0 EA.

27 301-11183 MSCR, FLT, HXS, 1/4-20X.75 SS 2.0 EA.

28 634-10642 WRENCH, ALLEN, 3/16, LONG ARM 1.0 EA.

29 634-11114 WRENCH, ALLEN, 5/32, LONG ARM 1.0 EA.

30 634-17242 WRENCH, ALLEN, 5/16, LONG ARM 1.0 EA.

Options

Truck mount kit; part #840-21751.