14 15

The pressure point is the lever position of the travel at which the

brake is engaged. If brakes function smoothly - there are no air bub-

bles in the hydraulic line - the pressure point is situated at the same

lever position at each braking action.

Do not touch the brake discs with your hands. The thin grease film

on your skin is transmitted to the brake discs and aects its func-

tions.

3.3. CHECKING THE CHAIN

The chain is a product subject to wear. Please check regularly the following

items:

»Are there any foreign objects (twigs) between the chain links?

-> If so: Remove them.

»Is the chain very dirty?

-> If so: Rinse it with water or a proper cleaning solution. Then use a first

class chain lubricant.

»Lubricate the chain at regular intervals, even when it is not dirty, in order to

prevent it from significant wear.

3.4. BATTERY: CHECKING THE FIXATION AND CHARGING STATUS

Check whether the battery is secured in the lock and see whether the charg-

ing status is sucient for your planned ride.

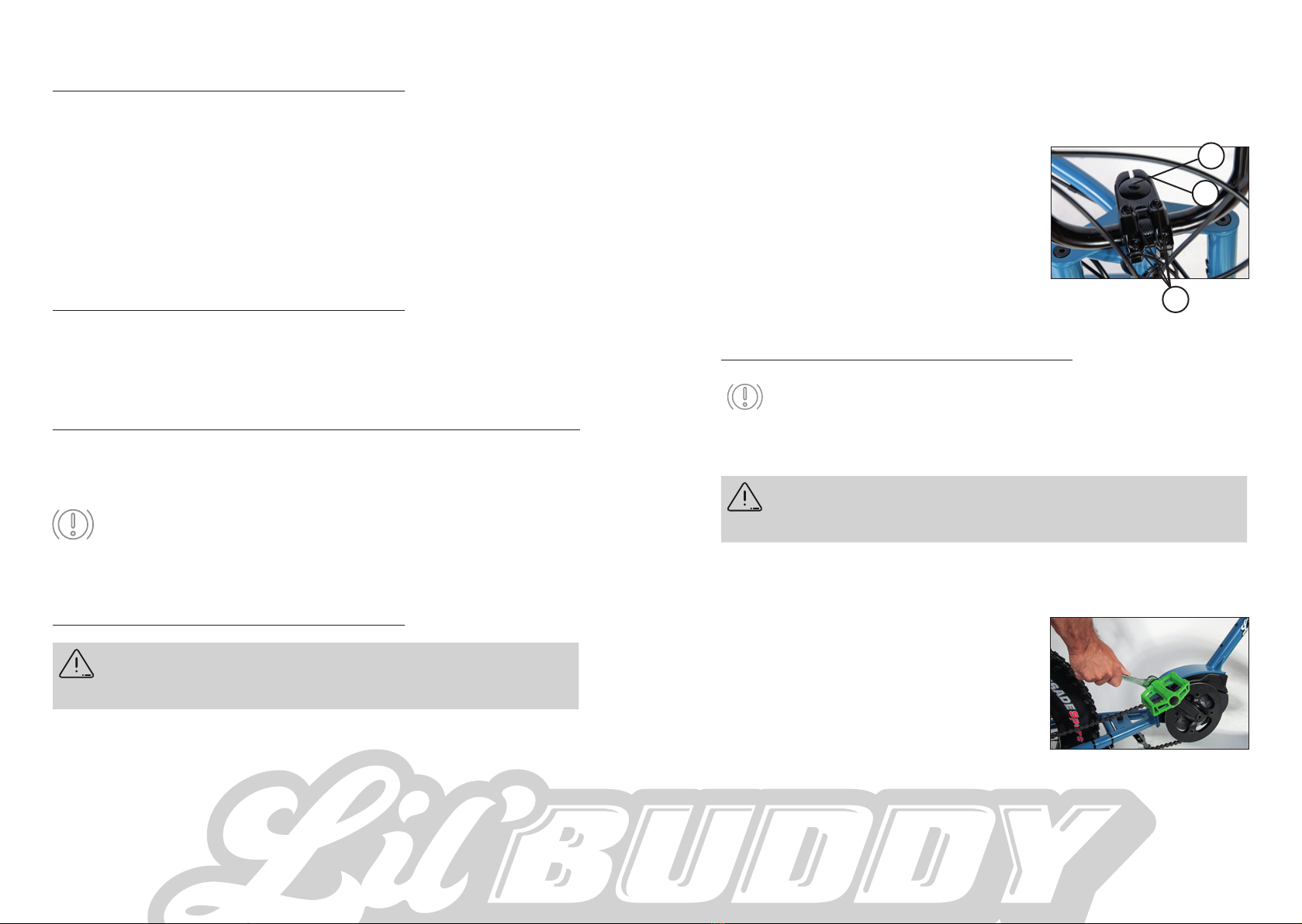

3.5. CHECKING THE FORK

Before each ride, check the fork for:

»Breakage and deformations

»Secure fixation of the protective plate

»Firm screwing connection of the fork bridge

BEFORE EACH RIDE

3. BEFORE EACH RIDE

3.1. CHECK TIRES

Tire pressure:

The allowed pressure range of the 20“ 98-406 is between 1 and 1.5 bar.

The following applies: The higher your weight, the higher the air pressure

to be used.

If you are not a light-weight person, set the pressure

of your rear tire at 1.5 bar.

We recommend to check the pressure every 2 - 4 weeks, since there

is an inevitable constant pressure loss of the inner tubes.

With a too low tire pressure, a puncturing hazard exists (snakebites).

This will result in a flat tire.

A tire that is damaged by tears or punctured by a sharp object may

loose its pressure. A hazard of accident exists!

-> Check that your tires are without tears or any foreign objects.

3.2. CHECKING THE BRAKE SYSTEM

»Before each ride, check your brakes at standstill. For this purpose, pull the

brake lever towards the handlebar with two fingers for a normal braking

force. The brake lever must not touch the handlebar grip

»Move the Pedelec while pulling the front and rear brakes. A too strong a play

is not allowed. If you notice any play, identify the cause. The brake calliper or

brake disc may not be tightened firmly. Tighten according to the torques in

the torque table in chapter 9.3.

»If hydraulic brake discs are used, the pressure point must be stable at the

brake lever. If the pressure point is not reached after 2/3 travel of the lever,

pull the lever several times in a row (“pumping”). Check whether the pressure

point has stiened. If so, or when the pressure point changes during the ride,

bleed the brake system by a specialist workplace.

»The brake discs must be oil-free. Any oil on the brake discs is removed with

alcohol. Do not use a conventional brake disc cleaning solution!

BEFORE EACH RIDE