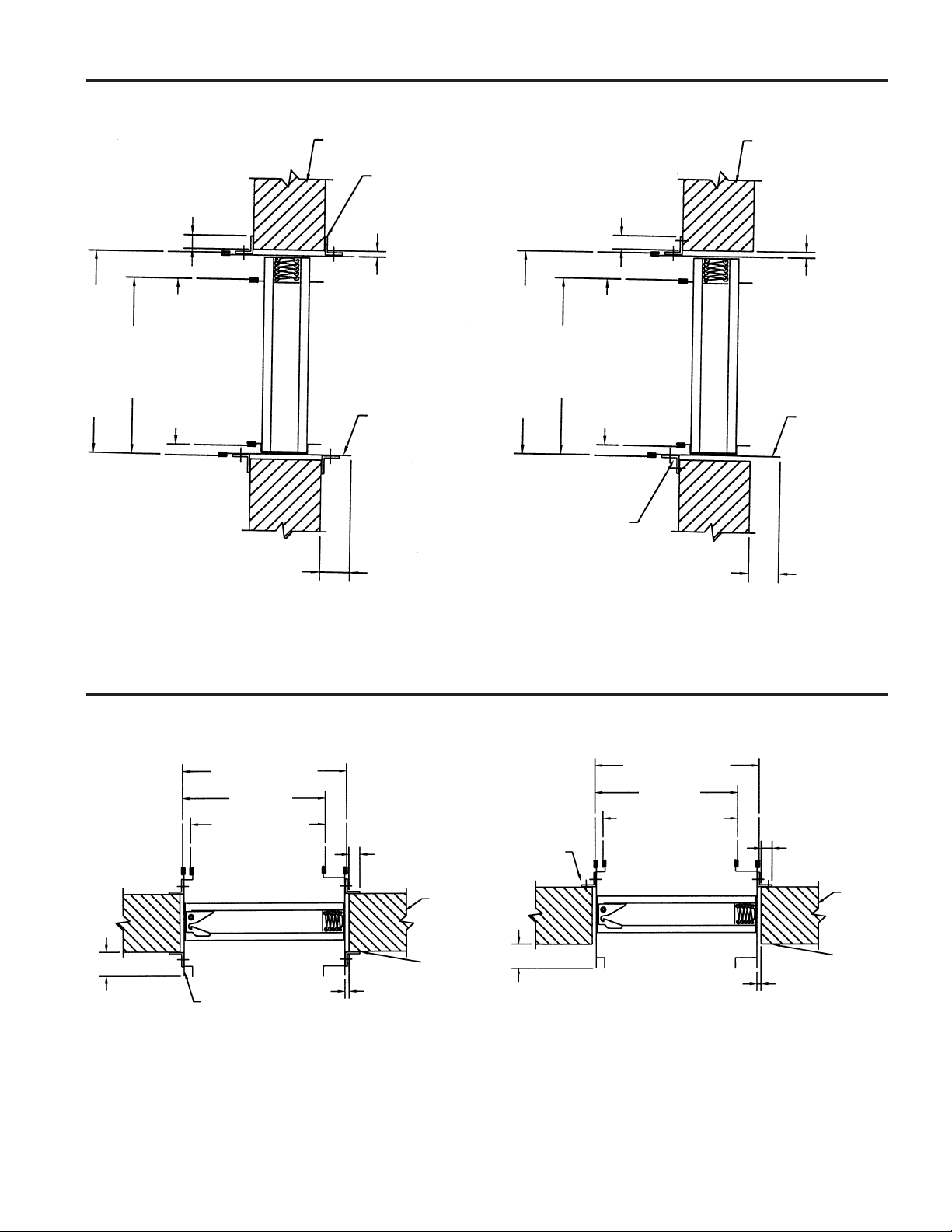

1. Opening Clearance

The opening in the wall or floor shall be larger than the

damper/sleeve assembly to permit installation or expansion. For

two angle installations the opening shall be a minimum of 1/8" per

foot (3 per 305) larger than the overall size of the damper/sleeve

assembly. The maximum opening size shall not exceed 1/8" per

foot (3 per 305) plus 2" (51), nor shall the opening be less than 1/4"

(6) larger than the damper/sleeve assembly. For one angle instal-

lations, the opening shall be a minimum of 1/4" (6) to a maximum of

1" (25) larger than the overall size of the damper/sleeve assembly.

The opening may be as much as 2” (51) larger than the damper/

sleeve assembly if a 16ga (1.6) mounting angles is utilized.

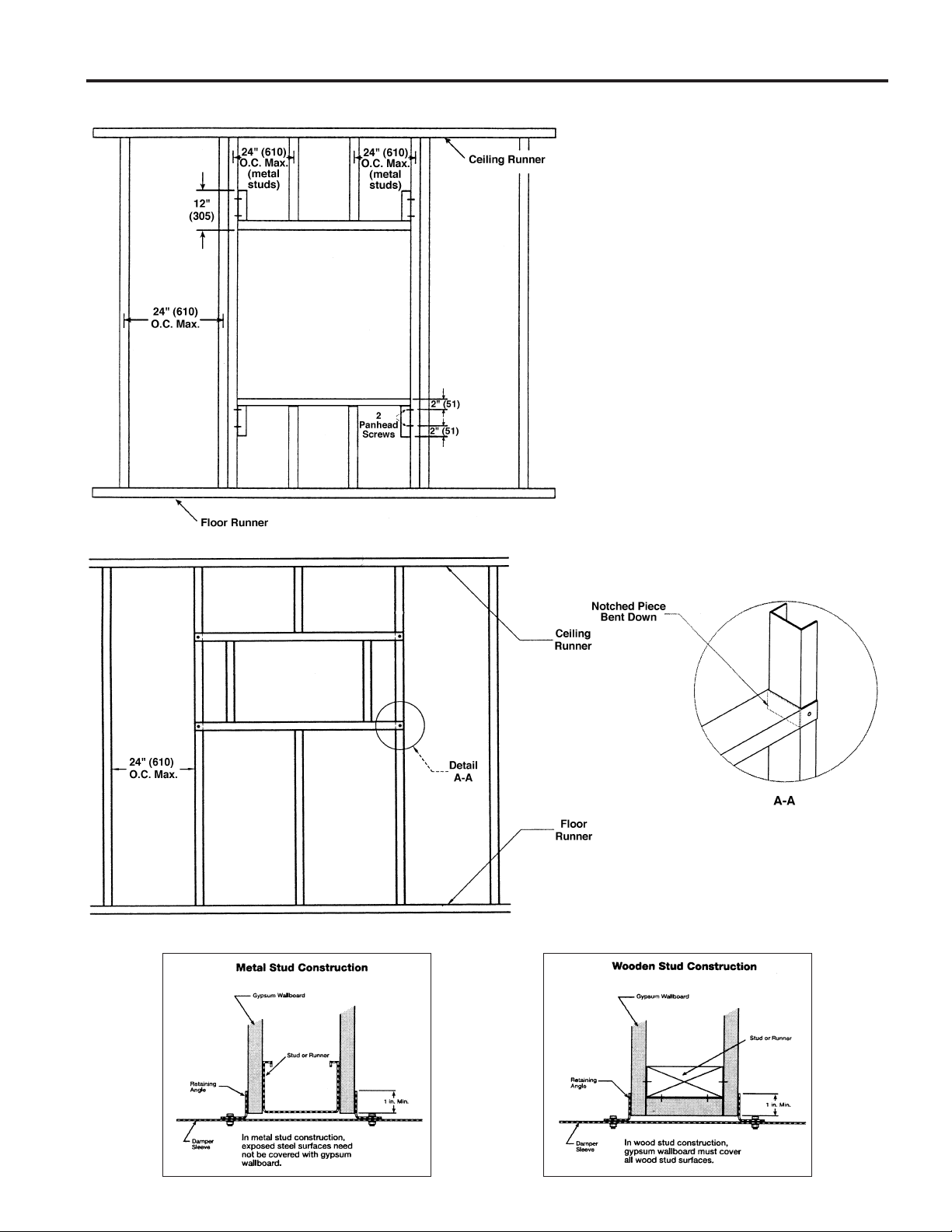

2. Fasteners and Multiple Section Assembly

Use No. 10 (M5) bolts or screws, 3/16" (5) rivets, tack welds or

spot welds as depicted in figures 3 and 4 and spaced as follows

when joining individual dampers to make multiple section damper

assemblies or when fastening damper to the sleeve:

Vertical Mount (In wall)

Galvanized steel dampers 12" (305) spacing

Stainless steel dampers 6" (152) spacing

Horizontal Mount (In floor)

All dampers 6" (152) spacing

Multiple section horizontal mount dampers require a 14 gage

thick x 41/2" (2 x 114) wide steel reinforcing plate sandwiched

between the damper frames with 1/2" (13) long welds staggered

intermittently and spaced on maximum 6" (152) centers. The rein-

forcing plate must be the same material as the dampers. The

length must be equal to the damper width of two or more adjoin-

ing damper sections. Reinforcing plates are not required for

assemblies consisting of two dampers attached end-to-end or

three dampers attached side-to-side as depicted in figure 5.

3. Damper Sleeve

Sleeve thickness must be equal to or thicker than the duct con-

nected to it. Sleeve gage requirements are listed in the SMACNA

Fire, Smoke and Radiation Damper Installation Guide for HVAC

Systems and in NFPA90A. If a breakaway style duct/sleeve con-

nection is not used, the sleeve shall be a minimum of 16 gage

(1.6) for dampers up to 36" (914) wide by 24" (610) high and 14

gage (1.9) for dampers exceeding 36" (914) wide by 24" (610)

high. Damper sleeve shall not extend more than 6" (152) beyond

the fire wall or partition unless damper is equipped with a factory

installed access door. Sleeve may extend up to 16" (406) beyond

the fire wall or partition on sides equipped with a factory installed

access door. Sleeve shall terminate at both sides of wall within

dimensions shown.

4. Damper Orientation

Use "Air Flow" and "Mount with Arrow Up" labels on Dynamic

DIBD and DIBDX models for proper damper orientation. For

Static IBD models use only "Mount With Arrow Up" label on

damper for proper damper orientation.

Static and Dynamic

dampers must be installed with leading edge of the closed

blades within the wall or floor.

5. Mounting Angles

Mounting angles shall be a minimum of 11/2" x 11/2" x 20 gage

steel (38 x 38 x 1.0). For openings in metal stud, wood stud walls

or concrete/masonry walls and floors of sizes 90" x 49" or 49" x

90" (2286 x 1245 or 1245 x 2286) and less mounting angles are

only required on one side of the wall or top side of the floor and

must be attached to both the sleeve and the wall or floor.

Mounting angles may be installed directly to the metal stud under

the wall board on metal stud wall installations only. arger open-

ings require mounting angles on both sides of the partition and

must be attached only to the sleeve. Mounting angles must over-

lap the partition a minimum of 1" (25). Do not weld or fasten

angles together at corners of dampers. Ruskin fire dampers may

be installed using Ruskin FAST angle for one angle installation or

Ruskin PFMA for two angle installations.

a. Mounting Angle Fasteners

Sleeve: #10 bolts or screws, 3/16" (5) steel rivets or 1/2" (13)

long welds.

Masonry/Wall or Floor: #10 self-tapping concrete screws.

Wood/Steel Stud Wall: #10 screws

b. Mounting Angle Fastener Spacing

For one angle installations the sleeve fasteners shall be

spaced at 6" (152) o.c. and the wall or floor fasteners shall be

spaced at 12" (305) o.c. with a minimum of 2 fasteners on

each side, top and bottom. Screw fasteners used in metal stud

must engage the metal stud a minimum of 1/2" (13). Screw fas-

teners used in wood stud must engage the wood stud a mini-

mum of 3/4" (19). Screw fasteners used in masonry walls or

floors must engage the wall a minimum of 11/2" (38). For two

angle installations the fasteners shall be spaced at 8" (203)

o.c.

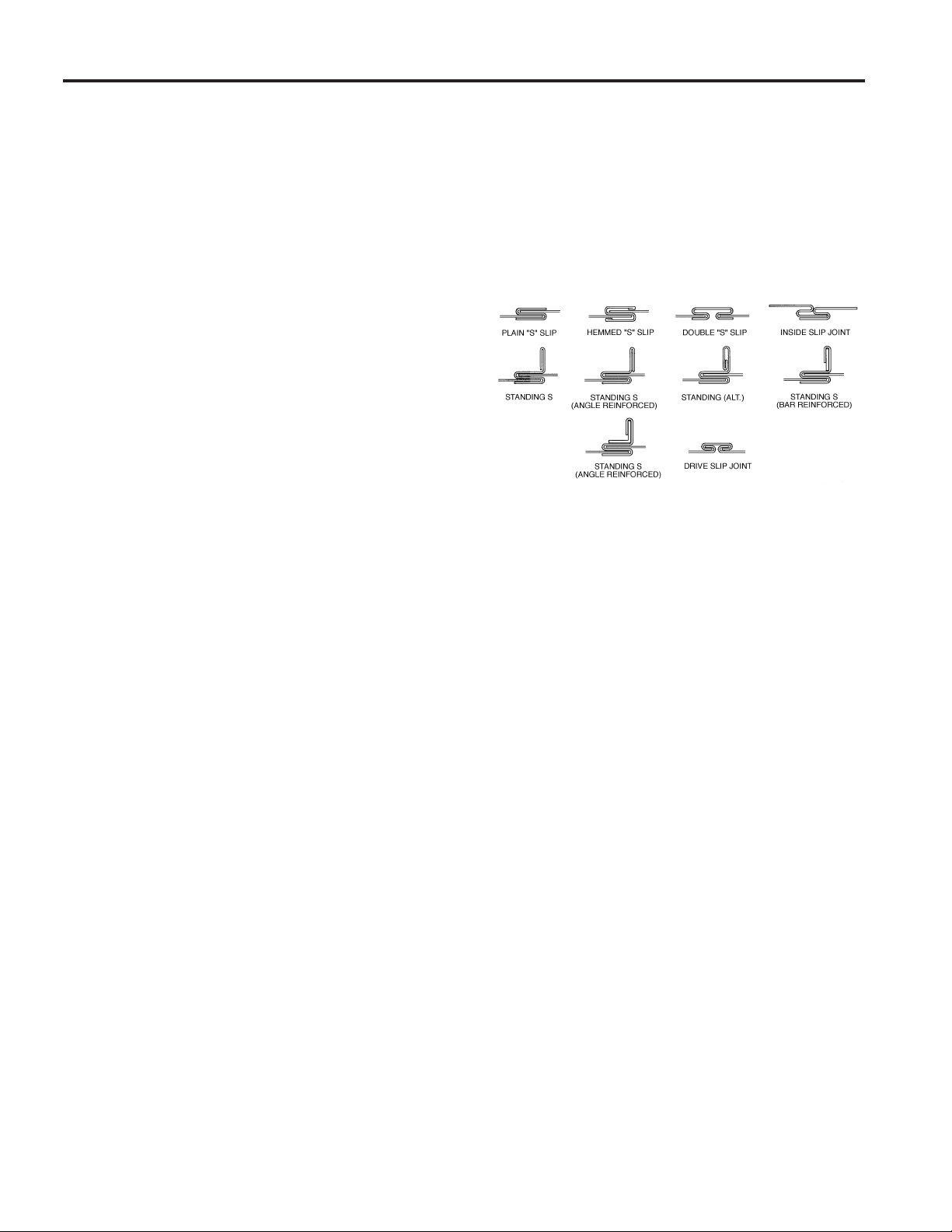

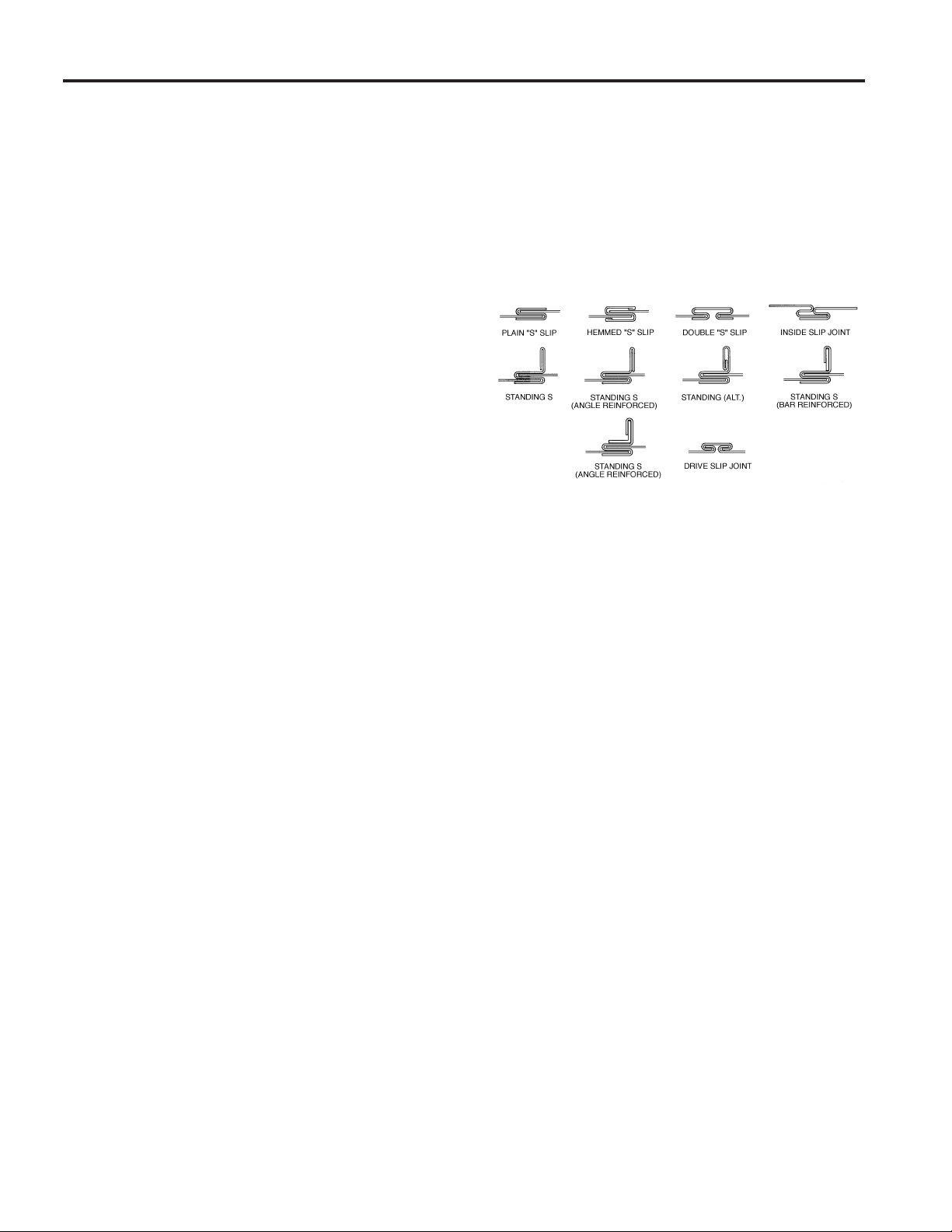

6. Duct/Sleeve Connections

a. Break-away Duct/Sleeve Connections

Rectangular ducts must use one or more of the connections

depicted: below:

A maximum of two #10 sheet metal screws on each side and

the bottom, located in the center of the slip pocket and pene-

trating both sides of the slip pocket may be used. Connections

using these slip joints on the top and bottom with flat drive

slips up to 20" (508) long on the sides may also be used.

b. Round and Oval Break-away Connections

Round and flat oval break-away connections must use either

a 4" (102) wide drawband or #10 sheet metal screws spaced

equally around the circumference of the duct as follows:

• Duct diameters 22" (559) and smaller – Maximum 3

screws.

• Duct diameters over 22" (559) and including 36" (914) –

Maximum 5 screws.

• Duct diameters over 36" (914) and up to and including

191" (4851) total perimeter – Maximum 8 screws. For flat

oval ducts, the diameter is considered the largest (major)

dimension of the duct.

Note: When optional sealing of these joints is desired, the fol-

lowing sealants may be applied in accordance with the

sealant manufacturer's instructions:

Design Polymerics – DP 1010 Precision – PA2084T

Hardcast, Inc. – Iron Grip 601 Eco Duct Seal 44-52

c. Flanged Break-away Style Duct Sleeve Connections.

Flanged connection systems manufactured by Ductmate,

Nexus or Ward are approved break-away connections when

installed as shown on the Flanged System Breakaway

Connections Supplement.

TDC and TDF roll-formed flanged connections using 3/8" (10)

steel bolts and nuts, and metal cleats, as tested by SMACNA,

are approved break-away connections when installed as

shown on the Flanged System Breakaway Connections

Supplement.

d. Non-Break-away Duct/Sleeve Connections

If other duct sleeve connections are used, the sleeve shall be

a minimum of 16 gage (1.6) for dampers up to 36" (914) wide

x 24" (610) high and 14 gage (2.0) for dampers exceeding 36"

(914) wide x 24" (610) high.

7. Installation and Maintenance

To ensure optimum operation and performance, the damper must

be installed so it is square and free from racking. Each fire

damper should be maintained and tested on a regular basis and

in accordance with the latest editions of NFPA 90A and local

codes. Care should be exercised to ensure that such tests are

performed safely and do not cause system damage.