A−A

B B

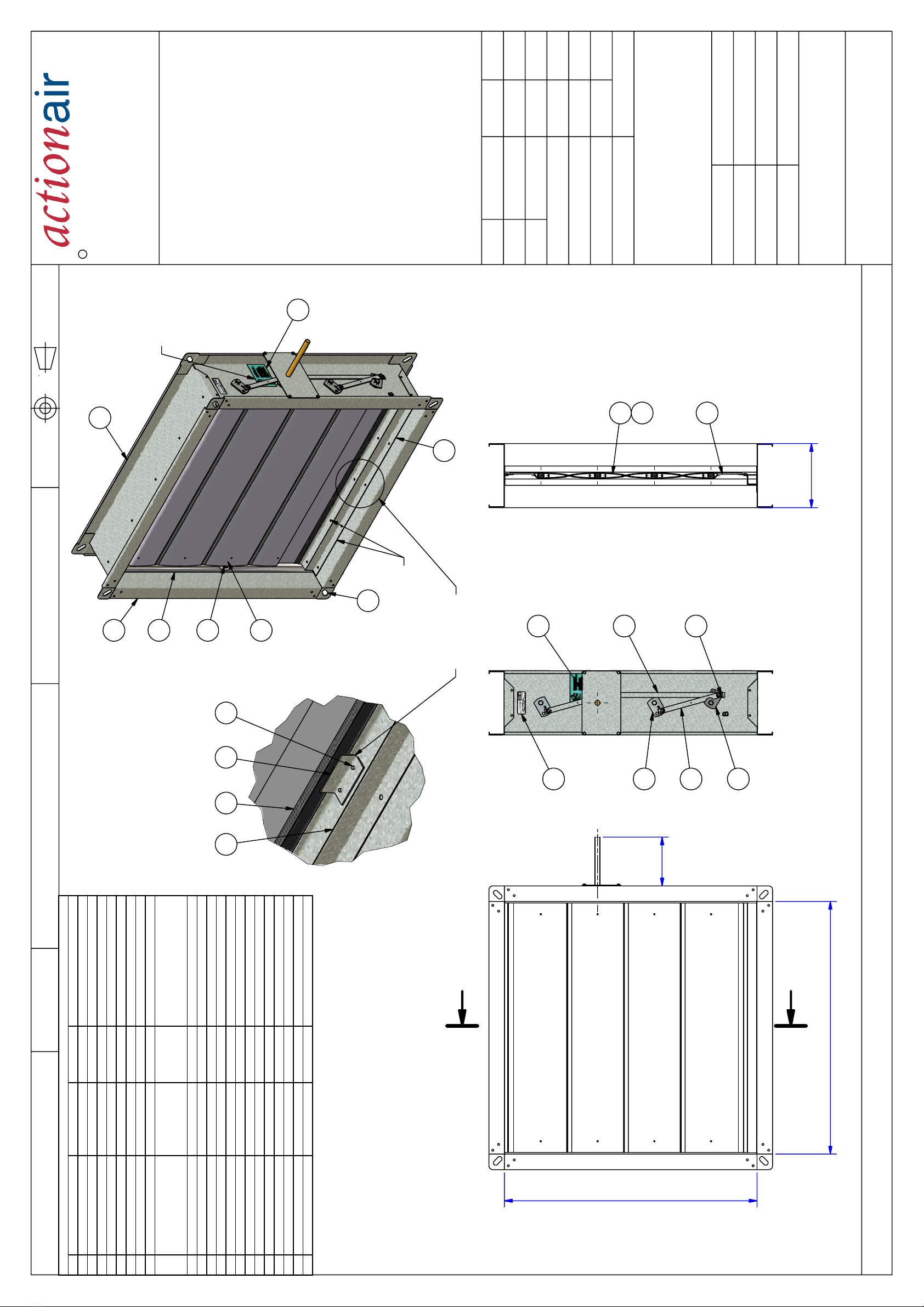

ITEM QTY DRAWINGNUMBER PARTNUMBER DESCRIPTION

1 2 ES35-001 SIDE FRAME

2 2 ES35-002 TOP & BOTTOMFRAME

3 SEE CHART ES50-003A CANN01835 TRIMBLADE

4 2 ES50-015 CNNN01833 ES50 BLADE STOP SEAL ASSEMBLY

5 2 ES36-005 CUNN01699 GASKET(SIDES)

6 SEE CHART ES50-006A CANN01817 STANDARD BLADE

7 8 ES35-007A/007C SEE DRAWING FLANGE CORNER BRACKET

8 1 (N>=3) ES35R-009 CSGN01802 LINKAGE TIEBAR

92N (WITHOUT TRIMBLADE)

2(N-1) (WITH TRIMBLADE) ES50-011A CNNN01836 ES50 BLADE SEAL

10 1 ES35-055 LNNN00010 DRIVING SHAFTLABEL

11 SEE DRAWING ES35R-016 CSGN01804 CROSSOVER LINKAGE "-"

12 SEE CHART ES50-050 SPACER

13 2N ES35-018 CPNN01690 BEARING

14 AS ITEM11 ES35-019 CSNN01691 "E" LINKAGE

15 N - ITEM14 ES35-020 CSNN01692 "F" LINKAGE

16 N USNN00073 E RING (E-25)

17 N ES35-027 CSZN01693 IDLER HEXAXLE

18 1 ES35-030 SEE DRAWING EXTENDED SHAFT KIT

19 1 ES50-054 LNNN00009 ES50 LABEL

20 2 (SEE NOTE 5) CNNN01933 FOAM

21 2 (SEE NOTE 5) ES50-056 CSGN01932 ES50 OVER TRAVEL STOP

22 4 (SEE NOTE 5) RSZN00054 FSD SELF PIERCE C'SK RIVET

N(NOB):THE NUMBER OF BLADES (SEE CHART)

PARTS LIST

DO NOT SCALE

ES50R−200

Draw No. 1

Rev. DIMENSIONS IN MILLIMETRES

C

RUSKIN AIR MANAGEMENT LIMITED

South Street, Whitstable

Kent CT5 3DU

Telephone: 01227 276100

Facsimile: 01227 264262

www.actionair.co.uk

ECN1031

16/05/2005

H Tang

Initials Dates

1

ES50R−200

Drawing No. Revision

Product

Part Number

Material

1

Rev Ecn

Ecn

Approved by

SEE PARTS LIST

N/A

Checked by

Drawn by

Finish

ES50R ASSEMBLY

Description

ES DAMPER

This drawing is confidential communication and is the property of Ruskin Air Management Limited and is returnable on request. It is not to be copied, loaned or communicated without the consent of Ruskin Air Management Limited.

This drawing should be considered uncontrolled if it is a printed copy, or has been transmitted outside of Ruskin Air Management Limited, electronically. The live version is the electronic copy held at Ruskin Air Management Ltd.

Please confirm the drawing issue before placing any orders which refer to this drawing.

A

A

NBDW

NBDH

D

NOTES:

1/ CLINCH THE BLADE STOPS ON THE TOP &

BOTTOM FRAMES (MAY ON THE SPACERS),

MAKE SURE THE BLADE STOPS PARALLEL TO

THE FRAME.

2/ AFTER ASSEMBLY, SEAL BLADE STOPS AND

SPACERS (IF PRESENT).

3/ STICK DRIVE SHAFT LABEL ON THE DRIVE

SIDE TO SHOW THE RECOMMENDED DRIVE

SHAFT LOCATION (SEE DRAWING ES35−021 ~

024).

4/ TAPE THE EXTENDED SHAFT KIT ON THE

TOP OF THE DAMPER.

5/ WHEN NBDW IS GREATER THAN 1000MM

AND WITH TRIM BLADES, STICK FOAMS (ITEM

20) ON THE TRIM BLADES, AND FIX ES50 OVER

TRAVEL STOP (ITEM 21) ON THE CENTRE OF

THE BLADE STOPS WITH RIVETS(ITEM 22).

6/ NBDW: NOMINAL BASE DAMPER WIDTH.

7/ NBDH: NOMINAL BASE DAMPER HEIGHT.

8/ D: FRAME DEPTH.

SEE NOTE 1 & 2

5

13

17

1

7

19

14

11

15

18

8

16

6

9

3

12

2

SEE NOTE 5

B

20 21 224

10

SEE NOTE 3

126

1221 HT 15/06/07

HT 18/06/07

MB 27/06/07