www.rusticwoodworking.com

9

SPECIFICATIONS

●Both of the cutters, 45° and 90°, can easily be adjusted to cut approximately 1” diameter up

to about 3” diameter tenons at the ends of logs and branches.

●Both the 45° and 90° cutters t onto the same shaft. The shaft has a at side on the drill-end

to prevent slippage during use.

●The maximum log diameter that the cutters will accept is about 4-1/2”. If you have a slightly

larger diameter log, you can shave it down at the edges by using a draw knife, shave,

manual or electric hand planer, or a saw so that it will t into the cutter.

●The maximum tenon length is about 2”, which is usually more than adequate. Take a look

at the Tips &Tricks section to learn how to measure and cut log lengths for curves.

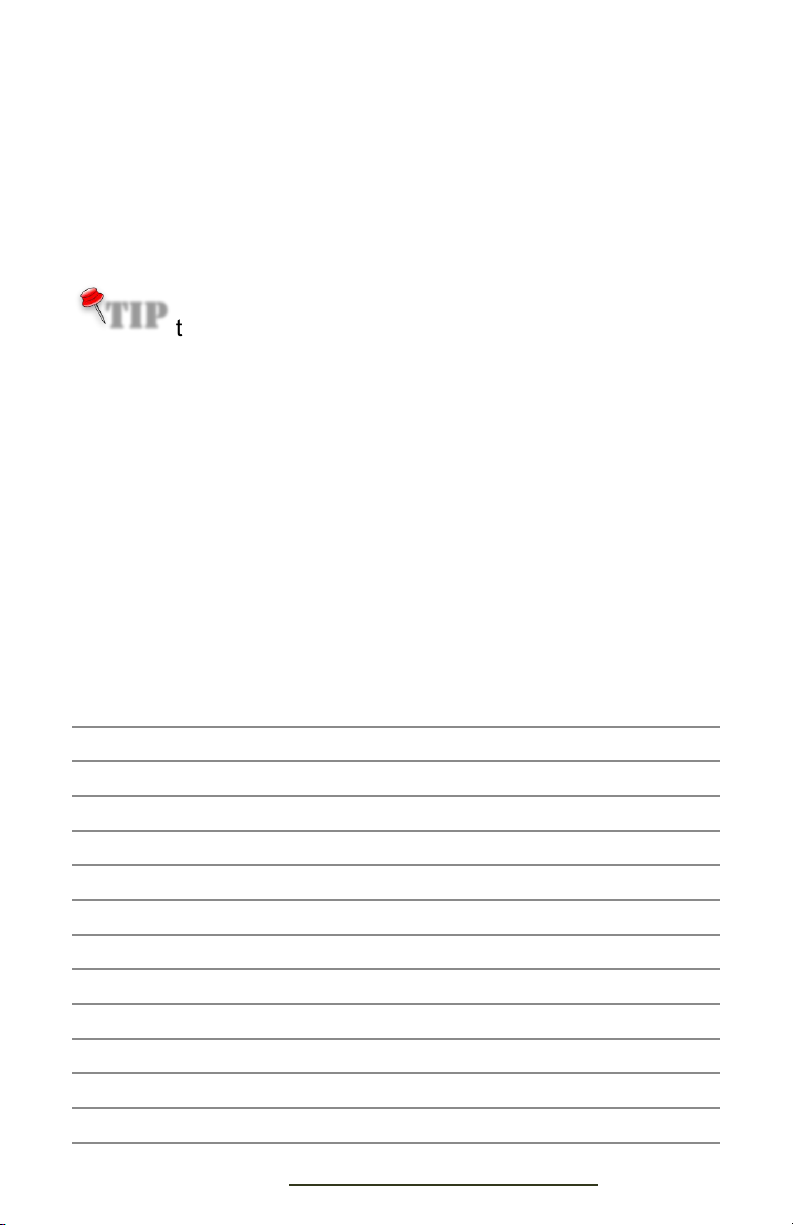

●The E-Z 45° Log Tenon Cutter uses one blade to cut a tenon, which is mounted on the

cutting arm and ready to use. There is also a spare blade which is stored on the non-

cutting arm. The E-Z 45° cuts a 45° shoulder on the sides of the tenon.

●The 90° E-Z Log Tenon Cutter uses two blades to cut a tenon, one on each arm. The 90°

E-Z Log Tenon Cutter will produce a at 90° shoulder on the sides of the tenon.

●The cutting blades are made from hardened steel, and have a cutting edge on both sides.

Each blade is like having two blades. When one side gets dull, use the included Allen

wrench to remove it and ip it over to use the other side.

●The blades for the 45° and 90° cutters are not interchangeable. The blades for the 45°

cutter are slightly longer than the blades for the E-Z 90° Log Tenon Cutter. If you need to

order replacement blades please be sure to order the correct size, and remember that the

90° uses two blades to cut a tenon, while the 45° only uses one blade.

●A pilot hole must be drilled into the end of the log prior to cutting a tenon. A 3/8” Drill Bit is

included to drill the pilot holes.

●The E-Z Log Tenon Cutters will t into any 1/2” drill. We recommend using the highest

powered drill you have with a side handle extra support.

●The drill guide inserts into the pilot hole to guide the cutter. This will help hold your drill

steady to create a smooth tenon.

●One 3/32” Hex Key is included to adjust tenon diameter, switch cutting arms, and to switch

bushings on the E-Z Log Sink (Countersink) bit.

●One 3/16” Hex Key is included to install or replace cutting blades.

●Two of the most popular sized bushings are included with the E-Z Log Sink. One is used to

countersink a 1.5” mortise, and the other to countersink a 2” mortise. Both bushings can be

attached to the Sink during use by tightening the set screws. The E-Z Log Sink is not a drill

bit. You must rst drill the mortise.

●A 3/8” drill bit is included to drill the pilot holes at the ends of logs and branches.

NOTE: We no longer ship printed versions of this Product Manual, the free Ratchet Strap Plan or

the Center Finder Plan unless requested. All are available to download for free from our website.