TABLE OF CONTENTS

DETECTOR ASSEMBLY...............................................................................................................3

BATTERY INSTALLATION............................................................................................................3

CONTROL PANEL.........................................................................................................................4

TURNING ON/OFF........................................................................................................................4

GROUND BALANCE.....................................................................................................................4

DISPLAY........................................................................................................................................5

OPERATING MODE SELECTION................................................................................................6

IDENTIFICATION..........................................................................................................................6

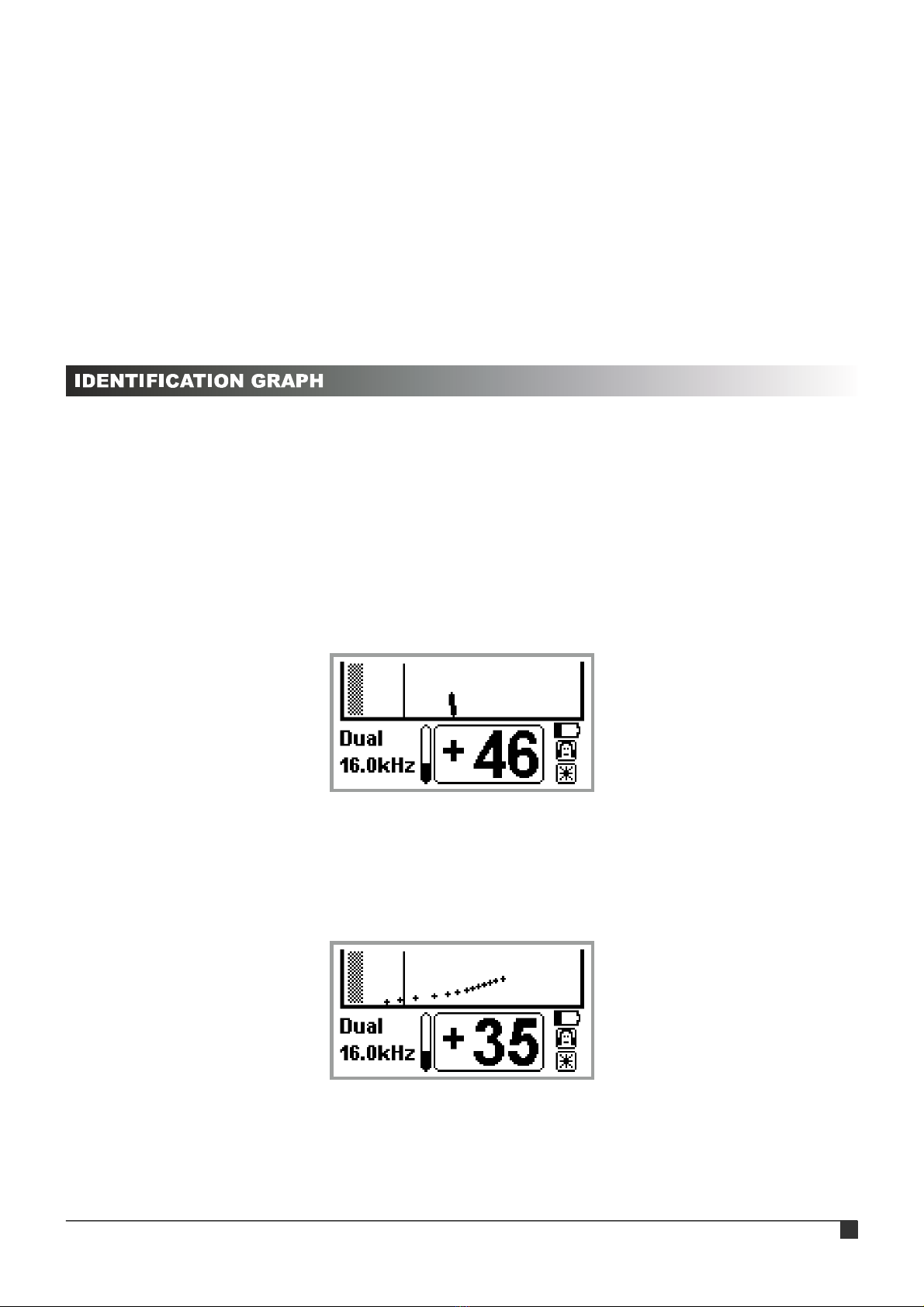

IDENTIFICATION GRAPH............................................................................................................7

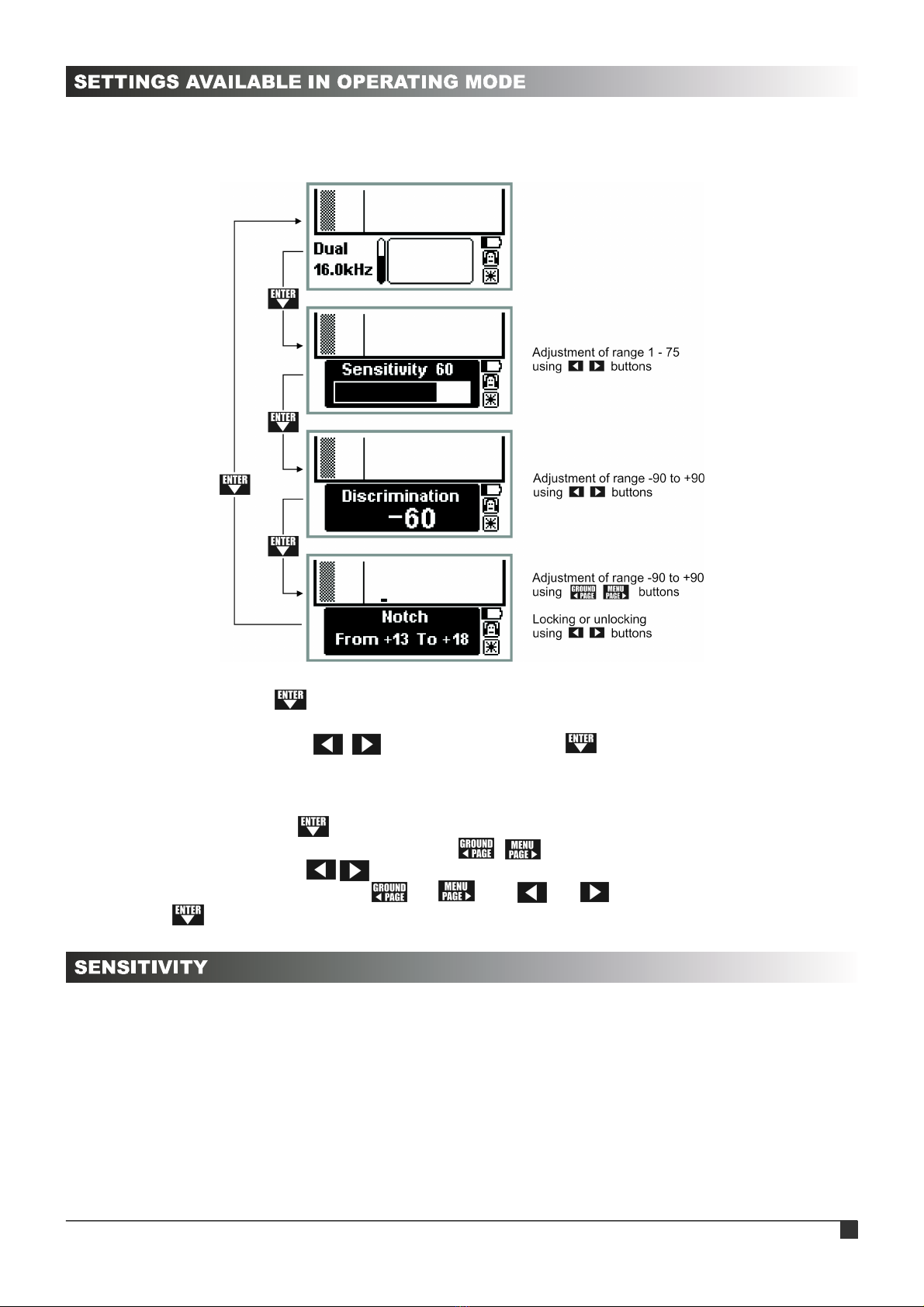

SETTINGS AVAILABLE IN OPERATING MODE...........................................................................8

SENSITIVITY.................................................................................................................................8

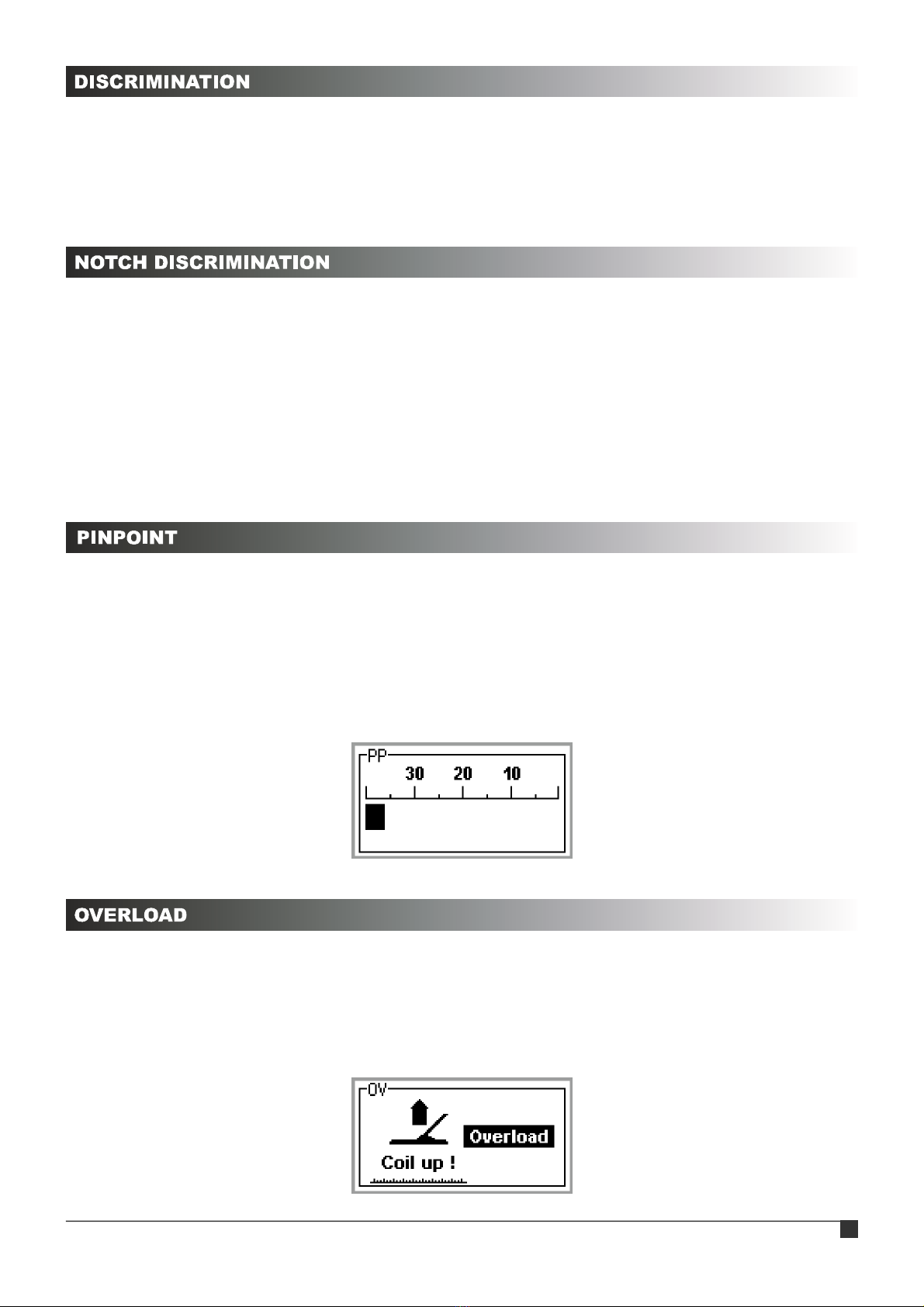

DISCRIMINATION.........................................................................................................................9

NOTCH..........................................................................................................................................9

PINPOINT......................................................................................................................................9

OVERLOAD...................................................................................................................................9

MENU LAYOUT...........................................................................................................................10

MAIN SETTINGS.........................................................................................................................11

Frequency..........................................................................................................................11

Frequency shift..................................................................................................................11

Hot Rock............................................................................................................................11

Backlight............................................................................................................................12

Volume...............................................................................................................................12

Wireless.............................................................................................................................12

Language...........................................................................................................................12

MOTION MODE SETTINGS.......................................................................................................13

Th Level.............................................................................................................................13

Th Tone..............................................................................................................................13

Tones.................................................................................................................................13

Audio Gain........................................................................................................................14

Masking.............................................................................................................................14

Reaction............................................................................................................................14

NON-MOTION MODE SETTINGS..............................................................................................14

Th Level............................................................................................................................15

Th Tone.............................................................................................................................15

VCO..................................................................................................................................15

SAT...................................................................................................................................15

DUAL MODE SETTINGS............................................................................................................15

DETECTOR'S CAPABILITIES.....................................................................................................16

MODES OF OPERATION...........................................................................................................17

MODES OF OPERATION AND SEARCHING.............................................................................19

SEARCHING – USEFUL ADVICE...............................................................................................19

NOTES FOR MAINTENANCE....................................................................................................20

EU DECLARATION OF CONFORMITY.......................................................................................21

RUTUS Argo NE