4

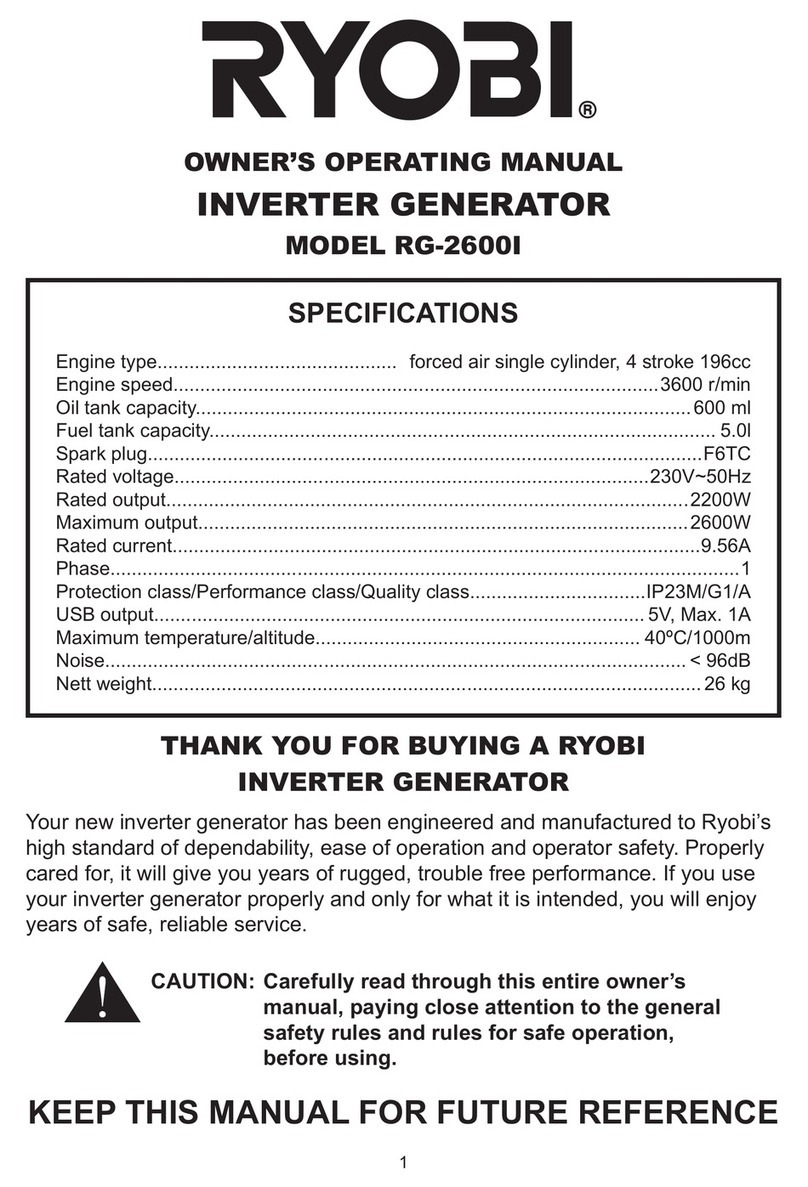

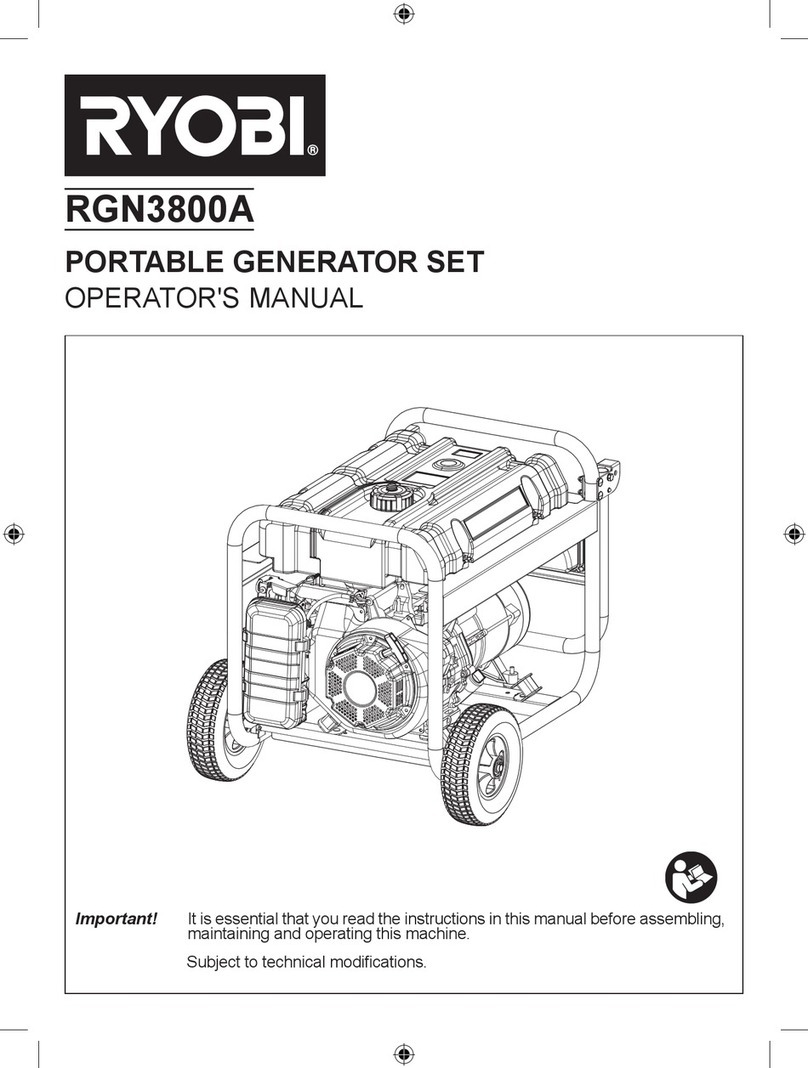

INTRODUCTION

This product has many features for making its use

more pleasant and enjoyable. Safety, performance, and

dependability have been given top priority in the design

of this product, making it easy to maintain and operate.

DANGER

GROUNDING THE GENERATOR (See Figure 1)

In Australia and New Zealand, grounding of portable

generators is not recommended or required. Consult

with local electricians to determine grounding

requirements before operating with a ground

connection.

IMPORTANT SAFETY INSTRUCTIONS

WARNING:

Read and understand all instructions. Failure

to follow all instructions listed below may result

in electrocution, fire, and/or carbon monoxide

poisoning, which will cause death or serious

injury.

WARNING:

Before using the ground terminal, consult a

qualified electrician to comply with the intended

use of the generator.

SAVE THESE INSTRUCTIONS

This manual contains important instructions that should

be followed during installation and maintenance of the

generator and batteries.

nDo not allow children or untrained individuals to use

this unit.

nNever start or run the engine inside a closed or partially

enclosed area. Breathing exhaust fumes will kill you.

nWear eye protection as well as hearing protection when

operating this equipment.

nKeep all bystanders, children, and pets at least 3m

away.

nWear sturdy and dry shoes or boots. Do not operate

while barefoot.

nDo not operate the generator when you are tired or

under the inuence of drugs, alcohol, or medication.

nKeep all parts of your body away from any moving parts

and all hot surfaces of the unit.

nProduct users in some states, must comply with re

prevention regulations. This product is equipped

with a spark arrestor in accordance with Australian

requirements.

nDo not touch bare wire or receptacles.

nDo not use the generator with electrical cords which

are worn, frayed, bare, or otherwise damaged.

nBefore storing, allow the engine to cool.

nDo not operate the generator in rain, snow, or wet

weather.

nEmpty fuel tank, close fuel valve, and restrain the unit

from moving before transporting in a vehicle.

nAllow engine to cool for ve minutes before refueling.

nTo reduce the risk of re and burn injury, handle fuel

with care. It is highly ammable.

nDo not smoke while handling fuel.

nStore fuel in a container approved for unleaded fuel.

nPosition the unit on level ground, stop engine, and allow

to cool before refueling.

nLoosen fuel cap slowly to release pressure and to keep

fuel from escaping around the cap.

nTighten the fuel cap securely after refueling.

nWipe spilled fuel from the unit.

nNever attempt to burn off spilled fuel under any

circumstances.

nUse only authorised replacement parts and accessories

and follow instructions in the Maintenance section of

this manual. Use of unauthorised parts or failure to

follow Maintenance instructions may create a risk of

shock or injury.

nMaintain the unit per maintenance instructions in this

Operator’s Manual.

nInspect the unit before each use for loose fasteners,

fuel leaks, etc. Replace damaged parts.

nThe generators vibrate in normal use. During and after

the use of the generator, inspect the generator as well

as extension cords and power supply cords connected

to it for damage resulting from vibration. Have damaged

items repaired or replaced as necessary. Do not use

plugs or cords that show signs of damage such as

broken or cracked insulation or damaged blades.

SPECIFIC SAFETY RULES

WARNING:

When this generator is used to supply a

building wiring system: the generator must be

installed by a qualified electrician and connected

to a transfer switch as a separately derived

system in accordance with Australian Wiring

Rules. The generator shall be connected through

a transfer switch that switches all conductors