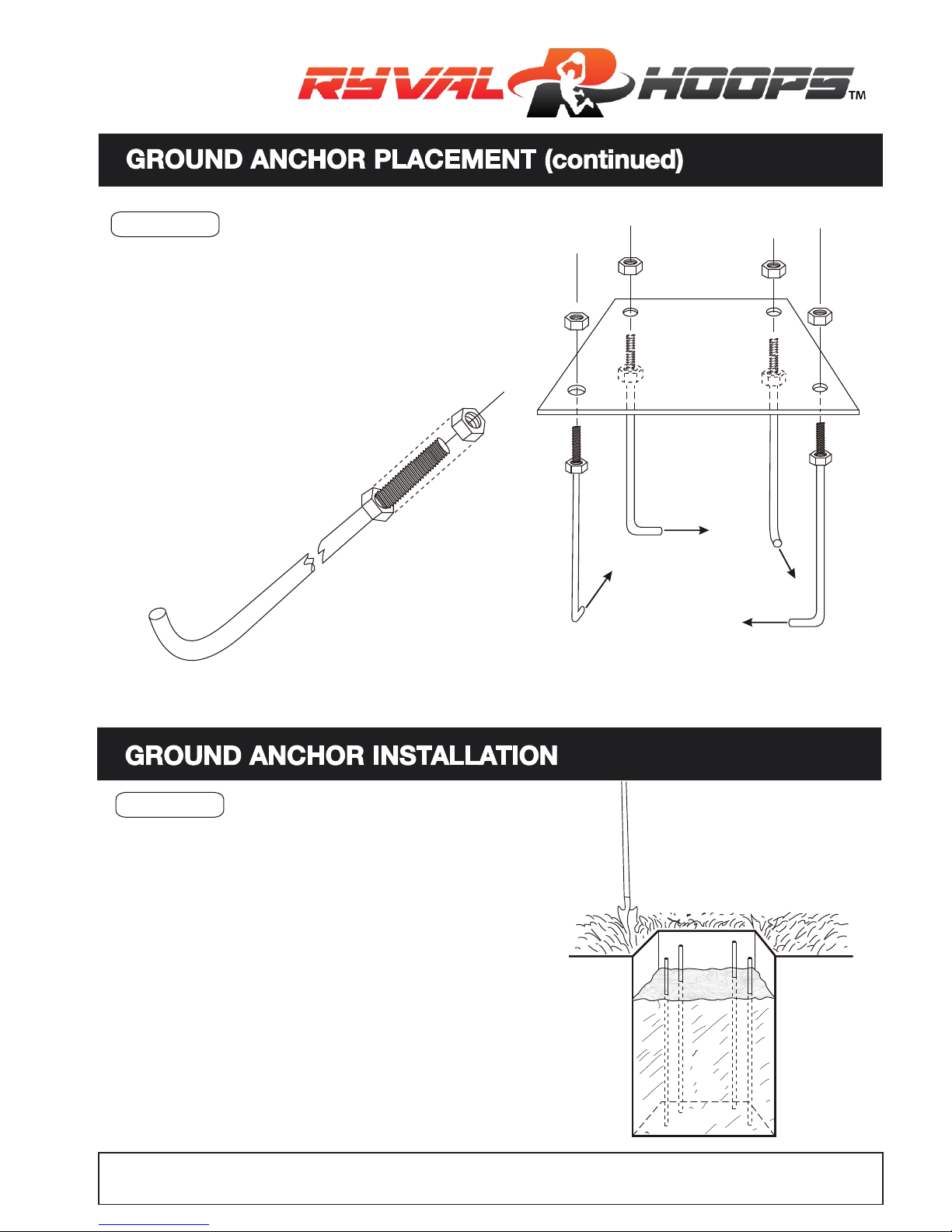

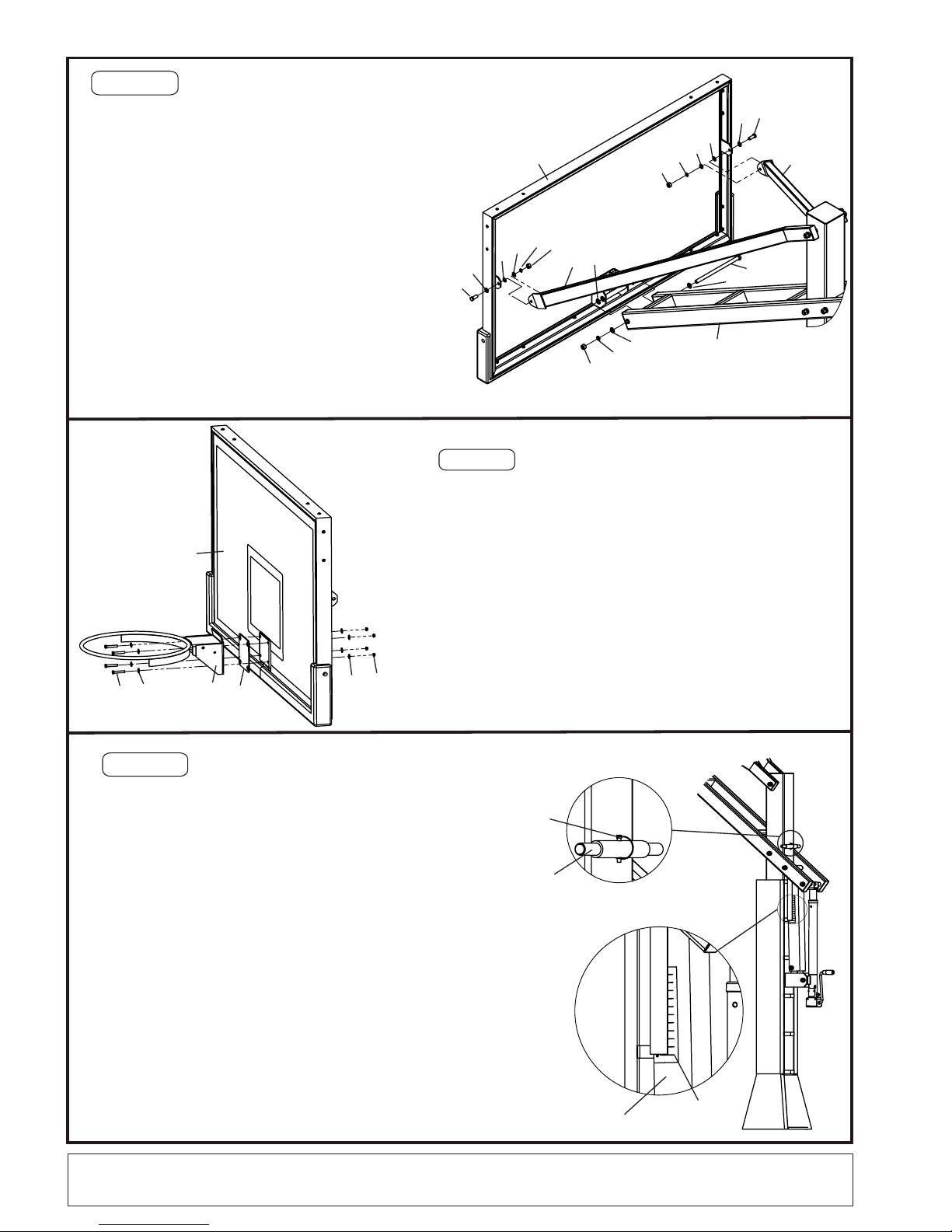

A. Slide the Actuator(B) to the last set of welded

tubes on the Main Extension Arm (F), Using a

Hex bolt M18X320MM (#5), two M18 Flat

Washers((#11), one Lock Washer (#14) and a Hex

Nut M18(#17) at the top. And using a

Hex Bolt M16x135mm (#9), two Washers for

M16 Bolt (#12), two Nylon washers (#2), and one

Hex nut for M16 bolt (#18) on bottom to tight

Note: make sure the Nylon washers go between

Actuator and Mounting Bracket.

the Actuator.

STEP 3

STEP 4

A.

B. Attach the bottom of Spring-assist Cartridges (C) to

the Main pole Bracket by using a

two Flat Washers M16 (#12), a Lock Washer M16 (#15)

a Nylon Washer M16 (#2) and a Hex Nut M16 (#18).

Note: Nylon washer goes between two Cartridges (C).

C. Remove and discard the White plastic spreader tube from the

Spring-Assist Cartridges(C).

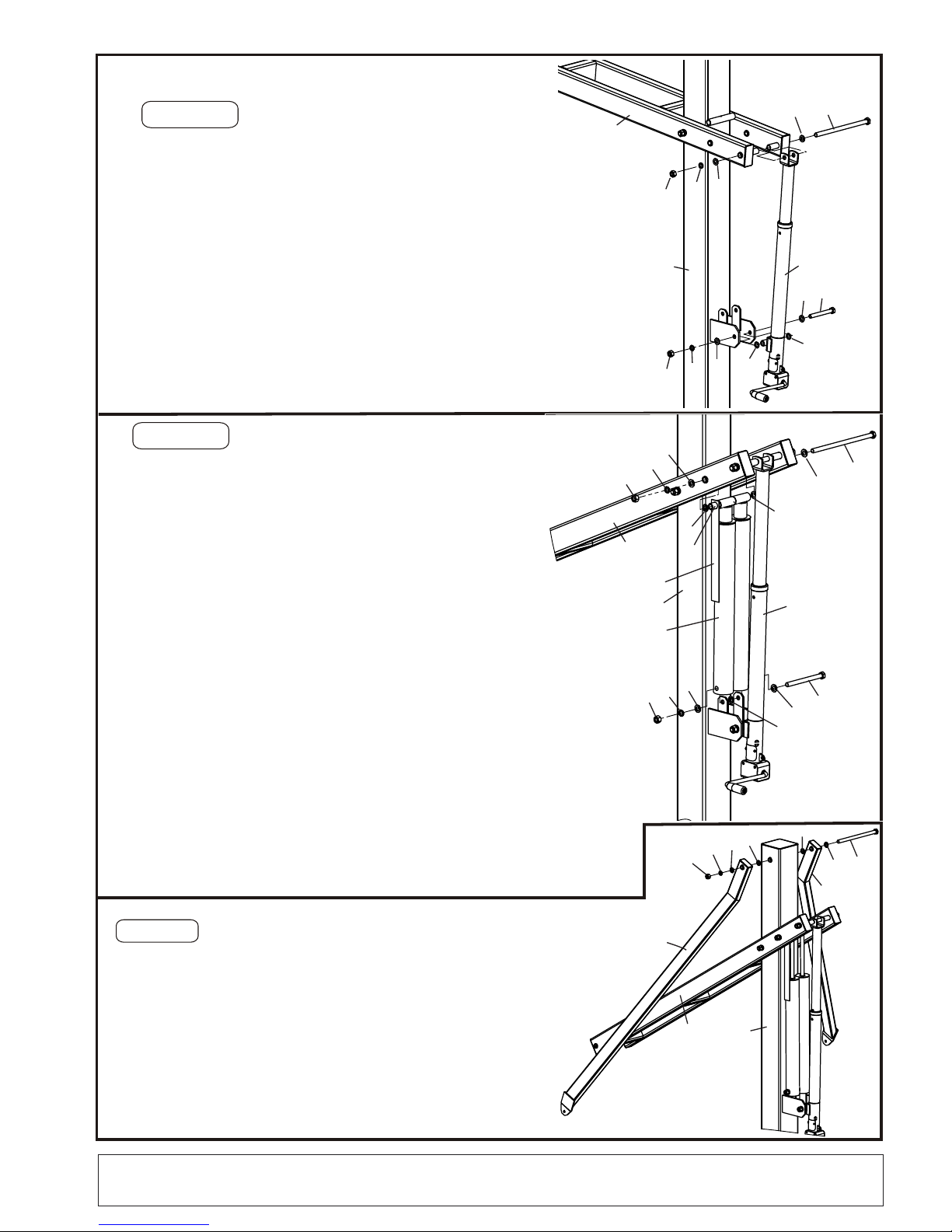

STEP 5

Slide Steel Sleeve (J) thru both tubes welded at the top end of

Spring-Assist Cartridge (C). Place the top of Spring-Assist between

Main extension (F), align the Steel Sleeve (J) with the second set of

welded tubes on the Main Extension Arm (F), place the Plastic rim

Height Indicator (K) beside the Spring-Assist Cartridge .

Slide one Washer M16 (#12) over one Hex Bolt M16x320mm

(#7), and slide this Bolt all the way thru Main Extension Arm (F), one

Nylon washer M16(#2), Steel Sleeve (J), Rim Height indicator

(K), another Nylon washer (#2) , and the other side of Main

Extension Arm (F). Secure it with one Flat Washer M16 (#12), one

Lock washer M16 (#15) and One Hex nut M16 (#18).

Do not over tighten this bolt because this is the pivot point.

Make sure the Plastic Rim Height Indicator(K) hang freely along side

of Spring-Assist Cartridge .

Nylon washer locates between Steel sleeves (J) and Main Extension

Arm (F).

9

12

2

2

12

15

18

B

A

5

11

11

14

17

F

7

12

12

15

18

2

J

2

K

A

F

B

C

8

12

12

15

18

2

Hex Bolt M16x185mm (#8),

6

12

2

G

G

2

12

15

18

FA

A. Attach the 2 Upper Extension Arms(G) to Main Post (A) with a Hex

Bolt M16x295mm (#6), two Flat Washers M16(#12), 2 Nylon washers

(#2), one Lock Washers M16 (#15) and one Hex Nut M16 (#18).

Do not tighten at this time.

9

WWW.RYVALHOOPS.COM

1 - 8 0 0 - 7 8 7 - 0 6 5 5