S-Helper Service Showcase Line EMD NW-2 User manual

tnginenttm

TTlonuat

NW-2,

SW-8

&

SW-9

SWITCHER

Tl-IE

SHOWCASE

L.INE"

Quality

S-scale

model

trains

from

S-Helper

Service, Inc.

S

HELPERSERVICE

INC.O2004

77

Cliffwood

Ave,Unit

7C,

Cliffwood,

NJ

07721

TABLE

OF

CONTENTS

SW-9-TofC

TABLE

OF

CONTENTS

THANKYOU

2

SECTION

I -

Prototype

Data

2

SECTION

2 -

Features

3

SECTION

3 -

Getting

Started

3

3-1

AC/DC

American

Flyer®

Compatible

Layouts

4

3-2

AlternatePilots

4

3-3

Couplers

5

3-4

Code

I

10

NMRA

RP-25

Wheelsets

6

3-5

AC/DC

Sound

Unit

7

3-6

DC

Polarity

Reversing

Options

8

3-7

DCC

(Digital

CommandControl)

8

SECTION

4 -

Maintenance

16

4-1

Lubrication

16

4-2

LED

replacement

17

4-3

Cleaning

17

4-4

Pick-up

wipers

replacement

18

4-5

HeavyDutyLubrication

18

SECTION

5 -

Parts

List

20

DRAWINGS

6-1

Bottomview

-

Gear

Box&

parts

5

6-2

Side

view-Truck

&

details

6

6-3

NMRA

socket

diagram

7

6-4

14

Pin

socket

Key.

7

6-5

10

Button

LocoMatic

Conroller.

12

6-6

LocoMaticConrollerwiring

14

6-7Dip

Switches

15

6-8

Cross-section

-

Gear

box&

parts

19

6-9

Explodedview

-

Body

&

chassis

22

WARRANTY..

GENERALDESCRIPTIONSW-9-Sec

I

THANKYOU

Thank

you for

purchasing

our

dieselswitcher.

Your

new

switchercomesready-to-run

on

AmericanFlyercompatible

S

gauge

track

with

either

AC

orDC

power.

Just

be

sure

to

break

in

yourswitcher

before

placing

itin

normaloperation.

Simplyoperate

itfor20

minutes

in

bothdirections

atmid

voltage(about

9

volts),lubricate

per the

instructions

in

Section4-1,

and

then

it's

ready.

We

haveincluded

additional

parts

for

easyadaptation

to

different

operating conditions.

Withpropercare

and

maintenance,yourdieselswitcher

shouldgive

youa

lifetime

of

operatingpleasure.

SECTION

I -

Prototype

Data

The

Electro-MotiveCorporationbegan

to

produce

600hp

dieselswitchers

inthe

late

'30s.

In

1940GeneralMotors

bought

EMCand

changed

its

name

to

Electro-MotiveDivision

(EMD).

Sincethen,evolvingdesignimprovementswere

incorporated

as

newermodelswereproduced.Modifications

includedincreasedhorsepower,multiple-unit(MU)options,

welded

construction,

and

changes

in

bodystyling.

EMD

sold

1149

NW-2s,

manufacturedbetween1939

and

1940,

779

SW-9s(1951-1953)

and369

SW-8s(1950-1953).Hundreds

of

railroads

and

industrieshave owned

these

switcherswith

many

still

inuse

today.

GeneralSpecifications:

Wheel

Diameter

40"

TruckWheelbase

8'-0"

Locomotive

Wheelbase

22'-0"

Length

44'-9"

Height

l4'-6"

Weight

248,000

Ibs

Horsepower

(NW-2)

1000

hp

Horsepower

(SW-8)

800hp

Horsepower(SW-9)

1200

hp

Speed

(max.)

55- 65mph

2

GENERAL

DESCRIPTION

SW-9-Sec

2

SECTION

2 -

Features

Right

outofthe

box,yourswitcherwill

runonany

layout

withAmericanFlyercompatible

track

and

standard

transformer,rectifier,

and/or

rheostat

speedcontrol.

Warning

- UseofAC

voltageshigherthan

21

volts

may

damage

the

electronics

and

willvoid

the

warranty.

Your

switchercomeswithseveraloptionalfeatureslisted

below:

(Thosewith

an

asterisk

(*)

are

factory-installed.)

•Two

sets

of

pilots.

a.

Standardhandrails*.

b.

A

second

set

withsplit

handrails

and

walk-

over

steps

forMU

operation.

•

Accepts

two

types

of

couplers.

a.

AmericanFlyercompatibleautomaticcouplers*

b.

SHS

#01295couplerswithincludedmachine

threadmountingscrews(coupler

not

included).

c.

Kadee

No.802

couplers(notincluded)

•Two

sets

of

wheels.

a.

AmericanFlyercompatible

wheelsets*.

b.

Code

110

NMRA

RP-25contourwheelsets.

•

Electronicoptions.

a.

AC/DC

sequence-reversing*.

b.

LocoMatic™

or

Sountraxx

DCC

sound

unit

c.

Reversing

headlights*.

d.

DC

shortingplug(cab

light

on)*.

e.DC

shortingplug(cab

light

off)*.

f.

DigitalCommandControl

(DCC)

NMRA

socket*.

•

Complete

setof

spareelectricalpick-upwipers.

The

following

paragraphs

tell

you how to set up

your

switcher

touseany

combination

of

thesefeatures.

SECTION

3 -

GettingStarted

You

can

perform

anyorallofthe

following

modifications

before

or

after

you

begin

to

operateyourswitcher.

Ifyou

haven't

yet

broken

itin

(seeSection4-1),

be

sure

todoso

before

placingyour switcherintonormaloperation.

3

GETTING

STARTED

SW-9-Sec3-l

3-1

AC/DC

American

Flyer

Compatible

Layouts

Your

switcher

has

American Flyercompatiblewheels

and

automaticcouplers.

It

also

has

factory-installed

forward-

neutral-reverse-neutralsequencing(1.0

sec

stop)

just

like

mostAmericanFlyerlocomotives.

In

order

to

enhanceyour

operating

enjoyment,

we

haveincluded

the

following

standard

ready-to-runfeatures:

•A

circuitdelay

so

that

the

locomotivedoes

not

cycle

intoneutral

in

case

power

is

momentarilyinterrupted,

as

withdirtytrack.

•

Directional lighting,only

the

headlight pointing

in

the

direction

that

yourswitcher

is

moving

lights

up.

•

Smart

reversing.Whenstopped

for30

seconds

or

more,

yourswitcherwillalwaysresumerunning

in

the

forward

direction.

Thesefeatures

areall

factory-installedwith

theno

sound

option.

3-2

Alternate

Pilots

Your

switchercomesready

to

operate

asa

single

unit.

If

you

want

toruntwo

units

in

tandem,

youmay

want

to

install

the

alternate

setofMU

pilots

ononeor

bothends

of

eachunit.Thesehavesplithandrails

and

fold-up

walk-over

steps

that

allowcrewmembers

to

walkbetween

the

units.

Both

pilotstyles

are

compatiblewith

either

the

American

Flyercompatiblecouplers

or

KD

style

No.

01295couplers.

To

replaceeachpilot,

lift

the

side

handrails

outof

their

sockets

onthe

pilot.Place

the

locomotiveupside

down

on

a

soft

protectedsurface.Unscrew

thetwo

screws

that

hold

the

pilot

in

place.

The

pilotshould

lift

straight

up.

Slide

the

alternate

pilotonto

the

chassis,

(ifthe

pilotdoes

not

seat

properly,trim

any

flash

from

the

bottom

ofthe

pilot)

replace

thetwo

screws

(Donot

overtighten),

andre-

insert

the

handrails.

GETTING

STARTED

SW-9-Sec

3-3

3-3

Couplers

If

you

wish

to

replace

the

AmericanFlyercompatiblecouplers

with

the

body

mounted

SHS

#01295

orKD

802/808couplers,

place

yourswitcherupsidedown

ona

soft

protectedsurface.

Carefully

remove

the

four

screws

that

hold

the

American

Flyercompatiblecouplerbracketassemblies

in

place

and

lift

off.

Each coupler

padonthe

chassis

has

three

holes

cored

for

mounting

the

Kadee

S

coupler.

TheAF

coupler

box

lid

with

front

flangeremoved

is

used

asa

spacerabove

the

KD802/808

orSHS

#01295couplerbox.

Please

usethe

six

threadedmetricmachinescrewsincludedwithyour

switcher

orthe

screws

that

held

theAF

couplerbracket

assy.

TheKD

screws

arenot

intended

foruse

with

a

metal

chassis

andmay

break.

•Donot

overtighten

the

screws

or

theywillbreak.

•Donotusethe

screws

that

come

with

the

Kadee

couplers;

these

are

designed

foruse

withplastic

or

wood

rather

than

metal.

Their

use

will

void

the

warranty

'pertaining

tothe

chassis.

6-1

Bottomviewpartsdrawing

-

gear

boxand

details

GETTING

STARTED

SW-9-Sec

3-4

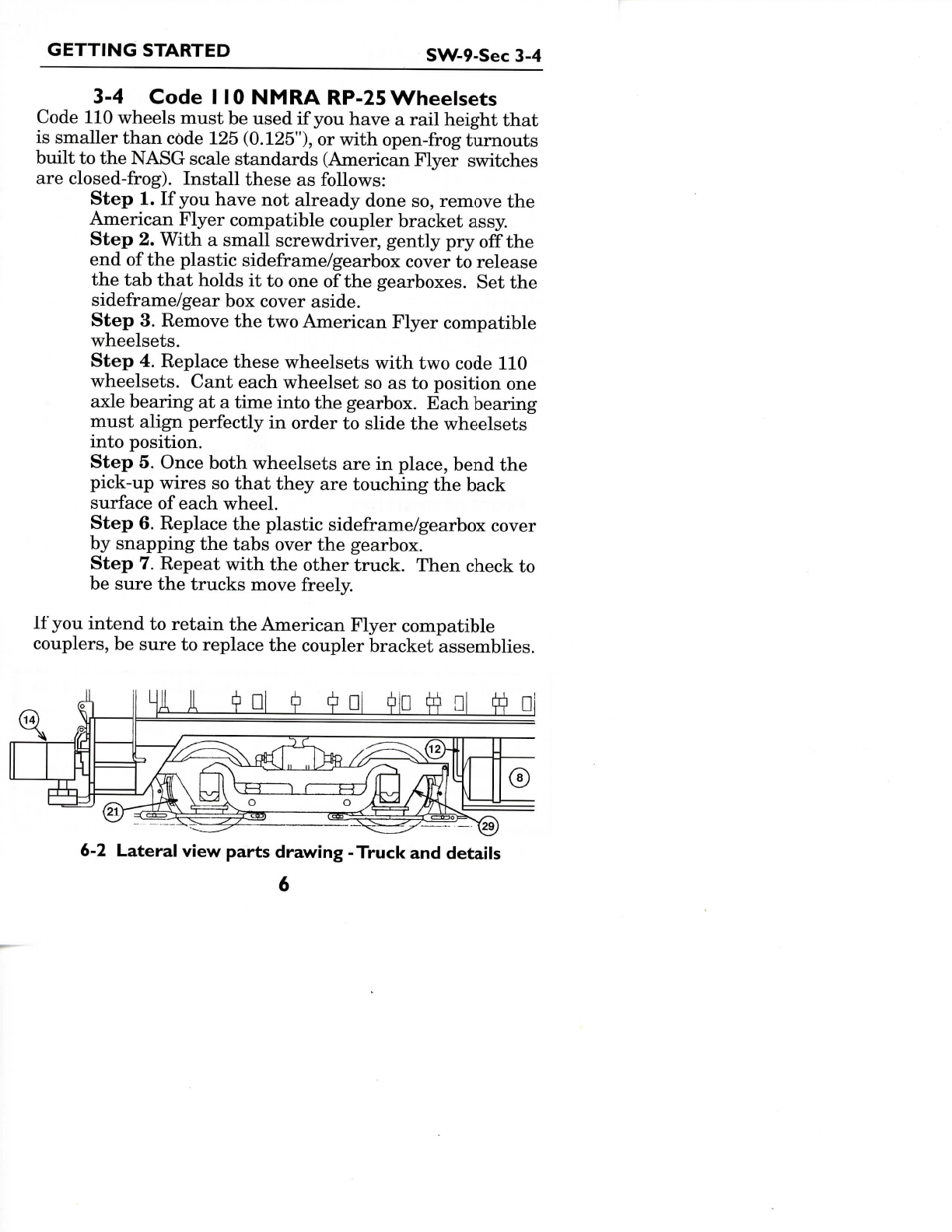

3-4

Code

I

10

NMRA

RP-25

Wheelsets

Code

110

wheelsmust

be

used

ifyou

have

a

railheight

that

is

smaller

than

code

125

(0.125"),

or

with

open-frog

turnouts

built

tothe

NASG

scalestandards(AmericanFlyerswitches

are

closed-frog).

Installthese

as

follows:

Step

1.Ifyou

have

not

alreadydone

so,

remove

the

American

Flyercompatiblecouplerbracketassy.

Step

2.

With

a

smallscrewdriver,gently

pry

off

the

endofthe

plasticsideframe/gearboxcover

to

release

thetab

that

holds

ittoone

of

the

gearboxes.

Setthe

sideframe/gear

box

cover

aside.

Step

3.

Remove

the two

AmericanFlyercompatible

wheelsets.

Step

4.

Replace

these

wheelsetswith

two

code

110

wheelsets.Canteachwheelset

soasto

position

one

axle

bearing

ata

timeinto

the

gearbox.Eachbearing

must

align

perfectly

in

order

to

slide

the

wheelsets

intoposition.

Step

5.

Oncebothwheelsets

arein

place,bend

the

pick-up

wires

so

that

they

are

touching

the

back

surface

of

each wheel.

Step

6.

Replace

the

plasticsideframe/gearbox

cover

by

snapping

the

tabsover

the

gearbox.

Step

7.

Repeatwith

the

othertruck.Thencheck

to

be

sure

the

trucks

move

freely.

If

you

intend

to

retain

the

AmericanFlyercompatible

couplers,

be

sure

to

replace

the

couplerbracketassemblies.

6-2

Lateral

viewpartsdrawing-Truck

and

details

6

GETTING

STARTEDSW-9-Sec

3-5

3-5

Alternate

AC

StartingDirection

Right

outofthe

box,your switcherwillalways

start

inthe

forward

(long

hood

in

front)

direction

ifithas

been

standing

for

more

than

30

seconds.However,

ifyou

wish

to

designate

thecabendas

"front"

(asyou

would

foroneoftwo

back-to-

back

units),

the

default

starting

direction

can be

reversed.

To

change

the

defaultdirection,remove

the

four

screws

that

hold

the

bodyassembly

tothe

chassis

and

lift

off

the

body.

You

will

find

a

smallsocket

just

behind

the

front

radiator

grille.(Thissocket

is

Part

No.16inthe

"cross-section

parts

drawing

-

gearbox

and

details"

on

page

11.)

In

this

socket

there

isa

slideswitchwhosepositiondetermines

the

default

locomotive

direction.

To

change

the

defaultdirection,simply

slide

the

toggle

tothe

oppositeside

ofthe

switch.Replace

the

body

onthe

chassis

and

secure

it

with

the

four

screws

(Do

not

overtighten).

Front

of

switcher

ooooooool

1

rp.

\3

•

10

1

2

3

4

11

OO

0000

0000

OO

9

8

7

6

5

12

Expanded

8 pin

NMRA

socket

(2:1)

6-3

Socketdiagrams

pin

I

2

3

4

9

II

function

motor(+/R)

light

-

rear

shorted

topin7

pick-up(L-fi

reman)

speaker

strobe

light

color

orange

yellow

-

black

purple

green

pin

5

6

7

8

10

12

function

motor(-/L)

light

-

front

light(common)

pick-up(R-engineer)

speaker

cab

light

color

gray

white

blue

red

purple

brown

6-4

Eight

Pin

NMRA

socket

Key

7

GETTING

STARTED

SW-9-Sec

3-6

3-6

DC

Polarity

Reversing

Options

WARNING:

Donotuse

this

feature

with

AC

current.

If

yourun

yourSW-9with

the

AC/DC

no

soundoption

on

a

layoutpowered

by DC,it

willoperateperfectly

and

cycle

reverse

the

same

asifit

werepowered

byAC.

Most

DC

layouts

useDC

polarity

to

reverse direction,however.

You

can

convertyourswitcher

toDC

polarityreversing.Access

the

reversingplug

by

following

the

instructions

inthe

previous

paragraph(Section3.5).Remove

the

factory-

installedplug

from

the

socket

and

replace

it

with

theDC

shortingplug,furnished

asa

separate

part

in

yourswitcher

packaging.

TwoDC

shortingplugs

are

provided,

one

with

thecab

light

onandthe

otherwith

thecab

light

off.

Once

the

plug

is

inserted,

setthe

body

onthe

chassis

and

test

the

locomotive.Replace

the

body

onthe

chassis

and

secure

it

with

the

four

screws

(Donot

overtighten).

3-7

AC/DC

LocoMatic™

Sound

Units

Another

optionavailable

for

yourswitcher

is

LocoMatic™

Control

withsound.Thisfeature

canbe

orderedfactory

installedwith

the

switcher,

or

purchased

later

for

installation

by

the

owner.Thisallows

the

unit

to

operatewith

ACor

DC

track

power

andis

different

from

mostother

LocoMatic™

systems.

It

does

not

contain

the DC

shift

for

operation

of

the

Horn

and

Bell.Therefore

it

requires

theuse

of

the

#00552

LocoMatic™

10

ButtonController

for

thesefunctions.

This

was

designed

forSHS

Inc.

by

DalleeElectronics,

Inc

andis

available

for

$69.95.

DC

operatorsshouldoperate

in

LocoMatic™

COMMAND

CONTROL

only.

If

operated

withvariable

DC

trackpower

in

standardmode,thennormal

AC

likesequencingwilloccur.

The

Horn

or

Bellwill

not

constantlyoperatingsince

the

decodingcircuitry

isnot

present

in

this

system.Conventional

AC

operation

follows

the

usualsequence

of

forward

-

neutral

-

reverse

-

neutral

-

forwardsequence

pattern

except

that

the

initial

state

is

switchselectable

for

either

start

in

forward

or

start

in

neutral.

A

locomotive

can

also

be

switchlocked

inthe

forward

8

GETTING

STARTED

SW-9-Sec

3-7

position

to

accomodateoperationunderautomatedsituations.

An

additional

direction

switch

is

provided

so

that

if

several

locomotives

arerunina

multiple

unit

lash-upsimply

set

this

switch

on

eachlocomotive

to

specify

whichdirection

is

forward,

engine.

Ifthe

direction

of

the

locomotive

is

opposite

of

that

desiredsuch

as

back

to

backoperation

as

commonly

seenwithswitchers.

SOUNDS

REPRODUCED

The

sounds

ofthe

switcherhavebeenrecorded

from

an

actual

locomotive

andare

prototypicallycorrect

for

utmost

realism.

HORN

is

useractivated

bythe

HORNbutton

ononthe

LOCOMATTC™

CONTROLLER.

The

hornwillplay

as

long

asthe

switch

or

button

is

held

on.

BELL

is

useractivated

bythe

BELLbutton

onthe

LOCOMATIC™

CONTROLLER.

The

BELLsoundwill

latch

"on"

when

the

bellcontrol

is

activated

and

willlatch "off

when

the

control

is

againactivated.

Any

BELLrequests

at

higherspeedswill

be

ingored.

The

BELL

canbe

activated

at

higher

speeds

if

requested

at

lowerspeeds

and

then

the

locomotive

speed

is

advanced.WhenBELLsound

is

requested,

the

soundsystemwillfirstadjust

the

diesel

sound

totheRPM

required

for

simultaneousplay.When

deactivating,

the

BELLwillstop

attheendofa

ring

and

the

dieselsoundwill

return

tothe

correct

throttle

setting.

BELL

sound

can

also

be

requestedwhendieselprimemover

sound

has

beenturned

"off1.

Again,

a

manualswitchallows

the

bell

tobe

deactivated

for

multipleunit(MU)operation.

AIR

SYSTEMRELEASE(POPS)

Airis

pumped

continuously

ina

diesellocomotive

to

maintainpressure

in

the

brakesystem

andfor

otherpurposes.Periodically,

accumulatedmoisture

and any

excesspressurewill

be

ventedthrough

a

releasevalve.These

AIR

RELEASEsounds

(pops)

are

generated

at

randomintervalsduringidle

and

atall

throttle

settings.

9

GETTING

STARTED

SW-9-Sec

3-7

BRAKE

RELEASEsound

is

producedwhen

the

locomotive

changes

from

neutral

toa

movementdirection

and

will

alwaysprecedelocomotivemovement.

PRIMEMOVER(Diesel)sounds

range

from

idle

to

full

RPM

witheight

throttle

notches.

In

neutral

or

with

no

power

tothe

motor

the

soundsystemwillproducediesel

engineidlesounds.When

a

movementdirection

is

selected

andthe

speedcontrol

is

advanced

toputthe

locomotive

in

motion,

a

brake

release

willsound(seeabove)

andthe

dieselsoundwill

initially

accelerate

to

about

throttle

notch

#4,

and

then

seek

the

correctnotch

setting

for

locomotive

speed.This

simulates

the

normaldelay

ona

diesel

locomotive

between

throttle

action

and

actual

movement.

Therewill

bea

distinctvolumeincreaseduringacceleration.

Soundvolumeshould

be

somewhatloweroncespeed

has

stabilized

and

should

be

reducedduringdeceleration.

Depressing

theALT/

FORWARD

button

onthe

LOCOMATIC

CONTROLLER

willdirect

the

soundsystem

to

accelerate

to

full

RPM

regardless

of

motorvoltage.

Depressing

theALT/

FORWARD

buttonagainwillrelease

the

soundsystem

to

return

tothe

correct

throttle

notch

setting.

Thisfeatureallows

the

simulation

ofa

heavy load

withveryslowlocomotivespeed

or

"pumpingair"

ina

standing

train.

LIGHTING

FEATURES

The

switcher

is

equippedwith

lighting

that

is

directional

so

that

the

headlight

will

illuminate

when

the

locomotive

isin

forwardmotion.When

the

locomotive

isin

reverse

motion

the

headlight

will

turn

off.

The

headlights

and

interior

cab

light

also

be

manuallyoperated

by

means

of

theSHS

#00552

LOCOMATIC™

CONTROLLER.

OPERATION

USING

ATRANSFORMER

With

this

sound

/

controlsysteminstalled,yourlocomotive

willoperate

inthe

samemanner

as

otherlocomotiveswhen

using

a

transformer

to

varyspeed.Whenpower

is

applied

the

locomotivewillcome"on"

in

either

the

forward

or

10

GETTING

STARTED

SW-9-Sec

3-7

neutralposition

asyou

haveselected.Momentary

interuptions

of

powerwillallow

the

locomotive

to

sequence

through

the

usualdirectionpositions.Sequencing

canbe

accomplished

either

bya

direction

switch/button

orby

turning

the

speedcontrol

to

"off

and

then

back"on".

An

added feature

of

this

sound

/

controlsysteminvolves

thewaythe

motor

is

driven,particularly

at

slowspeeds.

When

track

power

isat

lowervoltages

the

systemfurther

reduces

the

power

tothe

motor

soasto

provideextremely

smooth

slow

speeds

for

starting

and

stoppingyourtrain.

If

the

trackpowerfluctuates

at

theselowervoltages

you

may

notice

a

slight

surging

inthe

speed

ofthe

locomotive.

If

track

power

isset

highwhile

in

neutral

andyou

sequence

to

a

direction,

the

locomotivewillgraduallyincrease

its

speed

rather

than

jumpdirectly

tothe

highspeed.Thistype

of

operation

not

onlylooksbetter

but

also

results

in

less

strain

onthe

entiremotor

/

geardrivesystem

andis

less

likely

to

causederailments

ofthe

locomotive

orits

train.

SHS

#00552

LOCOMATIC™

CONTROL

Your

SHS

switcherwilloperatecorrectlywithyour

transformer

inthe

samemanner

as

traditionallocomotives,

but

with

the

simpleinstallation

ofthe

optional

LocoMatic

Control

Box,operationwill

be

greatlyenhanced.

The

LocoMaticControllercontains

ten

operating

buttons

and

is

usableeither

in

conjunctionwithyour regular

transformer

orasan

independentcontrolwith

a

fixed

voltage

applied

tothe

track.

The

LocoMatic

Controller

isa

pass

through

type

of

devicewhich

is

wiredbetweenyour

transformer

and the

track.

The

LocoMatic

Controlleritself

is

powered

bya 9

volt

DC

plug-inpowersupplywhich

is

included.

Some

ofthe

buttonscause activation

as

long

as

they

are

held"on"whileotherswork

ina

push-on,push-off

mode.

The

lower

right

handbutton,labled

'ALT',

isthe

alternatebuttonwhichprovides

a

second

function

to

each

of

the

otherninebuttons.

For

example;pressing

the

HORN

II

GETTING

STARTED

SW-9-Sec

3-7

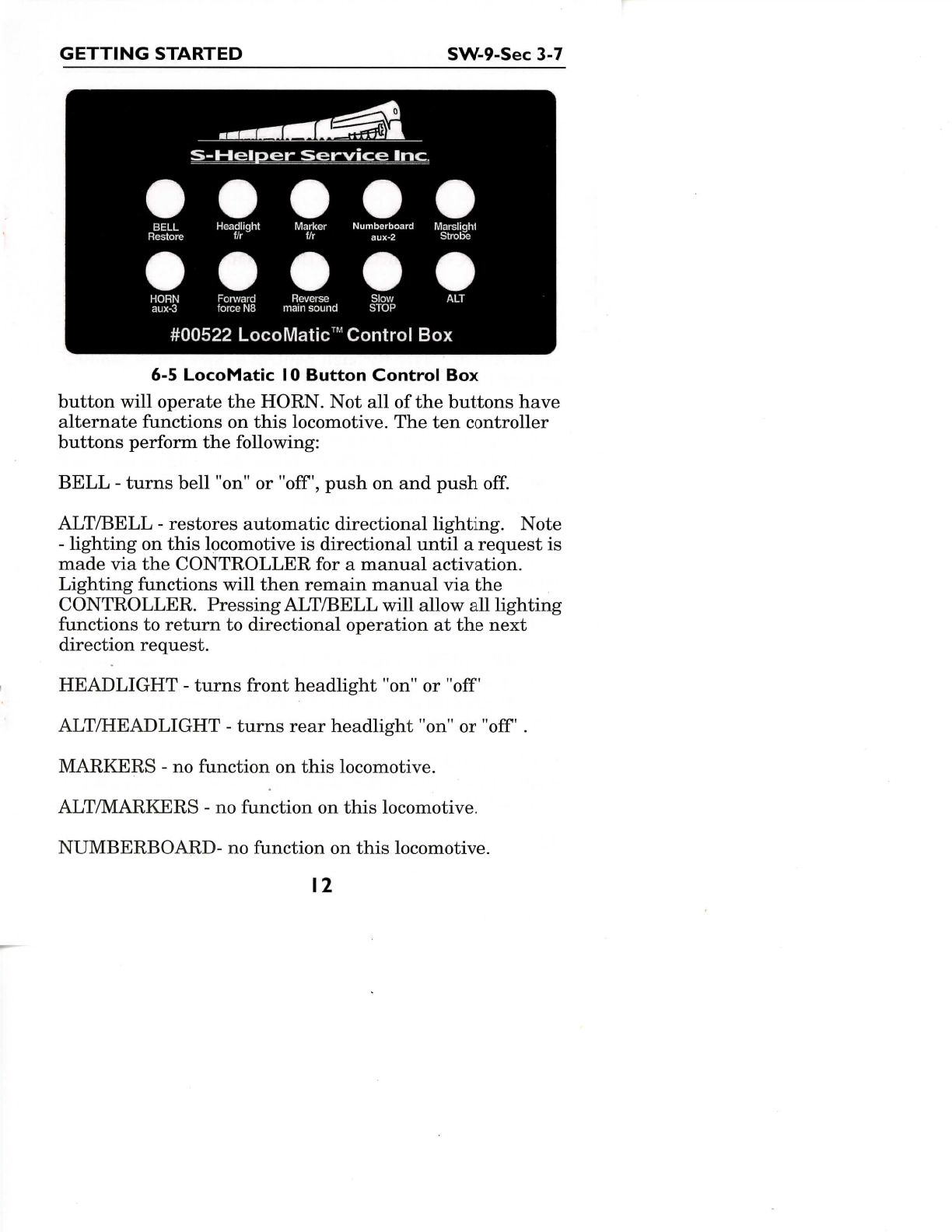

6-5

LocoMatic

10

ButtonControl

Box

button

willoperate

the

HORN.

Notallofthe

buttonshave

alternate

functions

on

this

locomotive.

Theten

controller

buttons

perform

the

following:

BELL

-

turnsbell"on"

or

"off',

push

onand

push

off.

ALT/BELL

-

restoresautomaticdirectionallighting.Note

-

lighting

on

this

locomotive

is

directionaluntil

a

request

is

made

viathe

CONTROLLER

fora

manualactivation.

Lighting

functions

willthenremainmanual

viathe

CONTROLLER.

Pressing

ALT/BELL

willallow

all

lighting

functions

to

return

to

directionaloperation

atthe

next

direction

request.

HEADLIGHT

-

turns

front

headlight"on"

or

"off

ALT/HEADLIGHT

-

turnsrearheadlight "on"

or

"off

.

MARKERS

- no

function

on

this

locomotive.

ALT/MARKERS

- no

function

on

this

locomotive.

NUMBERBOARD-

no

function

on

this

locomotive.

12

GETTING

STARTED

SW-9-Sec

3-7

ALT/NUMBERBORARD

-

turns

cab

light

"on"

and

"off.

MARSLIGHT/STROBE

- no

function

on

this

locomotive

ALT/STROBE

-

turns

strobe"on"

and

"off

HORN

-

activates

the

horn

ALT/HORN

- no

function

on

this

locomotive

FORWARD

-

forwardmotionoverriding sequencing

from

neutral

in

standardmode.Increasesspeed

in

command

mode

if

alreadyrunning

in

forward.

If

running

in

reverse,

speed

willdecreasethroughneutral

to

forward

depending

on

how

long

the

button

is

pressed.

ALT/FORWARD

-

this

forces

the

primemover

RPM

sound

to

full

speed(notch

8)

regardless

of

voltage

setting.

Use

this

to

simulate

pulling

heavy

drags,

pumping

upair

tanks

when

sitting

still,etc.Pressing

ALT/FORWARD

again

returns

RPM

sound

to

normal.

REVERSE

-

reversemotionoverridingsequencing

from

neutral

in

standardmode.Increasesspeed

in

command

mode

if

alreadyrunning

in

reverse.

If

running

in

forward,

speed

willincreasethroughneutral

to

reverse depending

on

how

long

the

button

is

pressed.

ALT/REVERSE

-

turns

OFF

mainsoundsleavingonly

the

Horn

and

Bell

if

selected

(only

the

horn

ifdip

switch

3 set

on).

Anotherpushwillrestore

the

mainsounds. Main

sounds

includebrakerelease,

air

pops

and

primemover.

SLOW

-

neutralposition overridingsequencing

toa

momentum

stop

- in

standardmode.Slowdown

a

step

per

push

of

button

in

commandmode.

ALT/SLOW

-

neutral

position

or

emergencystop.

13

GETTING

STARTED

SW-9-Sec

3-7

ALT

-

alternate

button

for

secondfunctions

of

other

9

buttons.

Must

be

helddown

in

conjunctionwith

one

otherbutton.

It

may

be

depressedfirst

and

heldwithout anotherbutton

leavingonly

one

otherbutton

to

press.

Notice:

Pressingmore

than

one

button,other

than

the

ALT,

produces

no

signal.

Itisan

invalidoperation.

INSTALLATIONOFTHE

LOCOMATIC™

CONTROLLER

Connect

two

wires

from

yourtransformer

tothe

terminals

on

the

CONTROLLER

labeledTrans,

IN.The

"B"

terminal

is

the

base

andthe

"16"

terminal

isthe

"hot".Thenconnect

two

wires

from

the

terminalslabeledTrack

OUTtothe

track.

The"B"

terminal

is

connected

tothe

inside

rails

of

your

track

andthe

"16"

is

connected

tothe

outer

rail.

This

installs

the

CONTROLLER

asa

passthroughbetweenyour

transformer

andthe

track.

We

recommendusing

#20

strandedwire,

asa

minimum,

for

these

connections.

Ifthe

CONTROLLER

isnot

"on",your transformerwill

still

function

normally.Connect

the9

volt

DC

powersupply

to

the

inputjack

onthe

CONTROLLER

and

plug

itin.The

CONTROLLER

isnow

"on"

andis

ready

to

operatewith

your

transformer.

In

summary,LocoMaticControlallowsfingertipoperation

of

a

uniquesound

and

controlsystemwith

the

additional

features

of

realistic,prototypicalspeed

and

directioncontrol.

Right

out

of

the

box,yourswitcherwillalways

start

inthe

forward

direction

ifithas

been

standing

for

more

than

30

trans,

tra

INOU

15

B

15

nnnn

I

,

FROM

•

TRANSFORMER

TO

TRACK

TO

9

VOLT

TRANSFORMER

6-6

LocoMaticControllerwiring

14

GETTING

STARTED

SW-9-Sec

3-5

seconds.

However,

ifyou

wish

to

designate

the

rear

endas

"front"

the

default

starting

direction

canbe

changed.

DIP

SWITCH

OPTIONS

-

MANUAL

ADJUSTMENTS

The

exhauststacksection

canbe

removed

to

reveal

the

LocoMatic

Soundunit.Grip

oneofthe

exhauststackswith

your

thumb

and

finger,

and

pull

straight

out.

It

just

snaps

in

place.There

are

four

dip

switches

anda

volumecontrol

on

the

smallcircuitboard.

The

soundpotentiometer

is

factory

setata mid

range

(12

o'clock).

Rotating

this

control

counter-clockwise

willincrease

the

volume.

Itis

suggested

that

the

volumecontrol

besetat

about

the

middle

of

its

range

for

comfortablelistening.

The

four

dip

switches

are

normally

settothe

"offposition

and

select

the

following

operations:

OFF

#

1

start

in

forward

#

2

sequencingnormal

#

3

bell

can

sound

#

4

forwarddirection

is

ON

neutral

lock

in

start

does

not

sound

front

rear

OFF-

-ON

-»•

m

i

Switches

3&4 are

usedprimarily

when

two or

morelocomotives

are

operatedtogether.

Youcan

turn

off

the

bell

inthe

trailing

locomotives.

Ifanyofthe

locomotives

are

actuallyfacing

to

the

rear,Switch

4 on

such

locomotives

allowsoperation

in

concert

withotherlocomotives

facing

forward.

When Switch

4

changes

forward

to

rear,

all

directionalfunctionssuch

as

5.7

p|p

Switches

headlights

are

switchedalso.

(enlarged)

3-7

DCC

(Digital

Command

Control)

A

DigitalCommandControl

(DCC)

decoder

isnot

included

withyourswitcher.However,yourlocomotivecomes

factory-

ready

to

receive

a DCC

decoderwithoutmodification*.

15

GETTING

STARTEDSW-9-Sec

3-7

Purchase

a DCC

decoder

from

a

vendor

of

yourchoice.

We

recommend

purchasing

a 1.0to2.0amp

decoder.

To

install

your

DCC

decoder,expose

the

reversing-plug

socket

by

following

the

instructions

in

Section

3.5.

Remove

the

factory-

installedprintedcircuitboard

(ortheDC

shortingplug)

and

plugyour

DCC

decoderinto

the

socket.Many

DCC

manufactures

offer

the

NMRA

mediumplug.

Factoryinstalled"Tsunami"

DCC

Sounddecoders

by

Soundtraxx

are

available.Thoseswitcherscomewith

an

additionalinstructionbooklet

on

their

operation

and

installation.

*

DCC

Installation

Note:

If

yourswitcher

hasa DCC

warninglabelattached

tothe

socketprintedcircuitboard,

it was not

wired

to the

NMRA

standards

and

willneed

to

be

replaced

for DCC

operation. Replacementsockets

are

available.Pleasecontact

SHS

regarding

our

replacement

program.

SECTION

4 -

Maintenance

4-1

Lubrication

Your

new

switcherdieselswitchercomesfactorylubricated

and

ready

forthe

break-inperiod.

After

break-in,

we

recommend

inspection

and

carefullubrication

ofthe

wheel

bearings.With

the

modelupsidedown,place

a

smalldrop

of

Aero

Lube"ConductaLube"

on

eachaxlenext

to

each

of

itstwo

bronzebushings

andthe

back

ofthe

wheels.

Use

only

a

drop,overlubrication

can

damage

the

body

as

well

as

void

the

warranty.

4-2

Golden

White

LEDs

The

LEDs

in

yourswitcher

are

rated

at3.5

volts

and30

milliamps

for

maximum

life

and

should

not

need

tobe

replaced. But,

just

in

case:

Step

1.

Remove

the

four

screws

that

hold

the

body

assembly

tothe

frame

and

lift

off

the

body.

Step

2.

Unplug

the

AC/DC

circuitboard.

Step

3.

Before

removing

LED

printedcircuitboard,

16

MAINTENANCE

SW-9-Sec

4-2

note

the

position

ofthe

wires

and

coppercontacts.

Rear

LEDs

(Steps

4-7):

Step

4.

Push

the

rear

LED

contactwires(brass)

to

the

side

Step

5.

With

a

smallflat-bladescrewdriver,release

thetab

below

thecab

sidewindows

and

remove

the

cab

floor.

Step

6.

Remove

theLED

circuitboardbracket

by

unscrewing

thetwo

phillips-head

screws.Gently

pull

the

contactwires

from

the

tabs

onthecab

roof

and

unsolder

thetwo

rear

bulbleads.

Step

7.

Solder

a newLED

circuitboardintoplace

and

attach

the

rear

LED

bracket.

Push

the

contact

wires

backinto

the

tabs

and

position

and

replace

the

cab

floor.

Re-install

cab

onto

the

body,

bend

the

contactwires

up,and

replace

rear

LED

wires

into

thesix

body

tabs.

Step

8.

Remove

the

front

LED

bracket

by

unscrewing

thetwo

phillips-head

screws.Replacewith

a new

LED

pcb

assembly

and

solder

in

place.Then

re-

attach

the

front

LED

bracket.

Step

9.

Re-insert

the

AC/DC

circuit-boardplug

(if

used)

into

its

socket.Thenre-attach

the

body

assembly

tothe

frame

(Donot

overtighten

screws).

4-3

Cleaning

Body

-

Removedustwith

a

small

soft

brush

(make-up

brush

or

similar).

If

yourswitcherrequiresmoreextensivecleaning,

we

recommendremoving

the

body

from

the

chassis

and

cleaning

the

body

with

dishwashing

detergent

anda

small

sponge.

Rinse withcleanwater(makingsure

nottoget

waterinto

the

interior

ofthe

cab)

and

blot

or

blow

dry

with

low

heat.

Pilots

canbe

removed

from

the

chassis

and

cleaned

inthe

sameway.

Wheels

-

Dirtwillbuild

up on the

wheeltreadsovertime.

To

remove

this

and

improvetraction

and

electricalpick-up,

we

recommendusing

91%

isopropalalcohol

anda

Q-tip.

17

MAINTENANCE

SW-9-Sec

4-3

Again,

remove

the

body

from

the

chassis,

asthe

alcohol

can

damage

the

body

finish.

Rub

eachwheeltreadwith

the

alcohol-moistened

Q-tip,applyingslightpressure

to

remove

the

dirtbuild-up.

The

wheels

canbe

rotated

by

hand-

turning

theflywheel.

Once

the

wheels'treads

are

clean,

check

the

electricalpick-upwipers

for

cleanliness

andfor

contact

against

the

insidesurfaces

ofthe

wheels.

Storage

-

Wheneveryourswitcher

is

withdrawn

from

service

for

an

extendedperiod,

we

suggest

you

store

itinits

original

foam

tray

and

gift

boxfor

maximumprotection.

4-4

Pick-upwipersreplacement

Step

1.

Using

a

smallscrewdriver,gently

pry

loose

theendofthe

plastic

sideframe/gearbox

cover

to

release

thetab

that

holds

ittothe

gearbox.

Step

2.

Remove

thetwo

wheelsets.

Step

3.

Remove

the

pick-up

wipers'bracketscrew.

Thenremove

the

worn pick-upwipers.

Step

4.

Replace

the

wornpick-upwiperswith

new

ones

and

reinstall

the

pick-upwipers'bracketscrew.

Step

5.

Re-insert

the

wheelsets.Note

that

the

bearingsmustalign

perfectly

forthe

wheelsets

to

slideinto

the

gearbox.

Step

6.

Oncebothwheelsets

arein

place,check

that

the

pick-up

wipers

areall

contacting

the

inside

surface

of

the

drivers.

Step

7.

Replace

the

plastic

sideframe/gearbox

cover

by

snapping

the

tabs

over

the

gearbox.

Step

8.

Check

tobe

sure

the

trucks

move

freely.

4-5

Heavy

Duty

Lubrication

If

yourswitcheroperates

ona

clublayout,

at

shows,

or

receives

unusuallyheavyusage,

the

worm

and

idlergears

will

needperiodiclubrication

to

preventexcessivewear.

To

lubricatetheseareasmost

effectively,

completedisassembly

of

the

gearbox

is

necessary.

Step

1.

Remove

the

four

screws

that

hold

the

body

assembly

tothe

frame

and

lift

off

the

body.

18

MAINTENANCE

SW-9-Sec

4-5

Step

2.

Unplug

the

AC/DC

circuitboard

(if

you

are

not

using

DC

polarity

reversing

or

DCC)

andthetwo

forward

and

reverse lightplugs.

Step

3.

Remove

the

AmericanFlyercompatible

coupler

bracket

andthe

four

wheelsets.(See

Code

110

NMRARP

25

ContourWheelsets,Section4.4.)

Step

4.

Remove

the

e-clips

that

hold

the

gearbox

to

the

geartower

and

lower

the

gear

box

from

the

chassis.

Step

5.

Remove

the

plasticpick-upwiperassembly,

taking

care

notto

break

the

wipers.Note

on

which

side

ofthe

gearboxeachbelongs.

Step

6.

Remove

thetwo

screwsholding

thetwo

halves

of

the

gearboxtogether.Once

the

gearbox

is

apart,

clean

theold

grease

from

the

gears

and

worm.

Lubricate

the

wormwith

ACT

gearLube

andthe

idlergearswith

ACT

motorbearinglube.

Step

7.

Re-assemble

the

gearbox

(Donot

overtighten

screws)

and

plasticpick-upwire

assembly.Carefullyre-connect

the

universaldrive

shaft

tothe

geartower

and

push

the

e-clip

backonto

the

gearbox stem.

Step

8.

Re-insert

the

AC/DC

circuitboardpluginto

6-8

Crosssectionpartsdrawing

-

gear

boxand

details

19

This manual suits for next models

2

Table of contents

Popular Toy manuals by other brands

Learning Resources

Learning Resources GEARS! MOTORIZED Wacky Wigglers Building Set instructions

twinkl

twinkl Foil Sparklers quick start guide

Horizon Hobby

Horizon Hobby Hangar 9 Spitfire 60 ARF Assembly manual

Comet

Comet 33206 instruction manual

LEGO

LEGO technic 8110 instructions

VERTBAUDET

VERTBAUDET Sirius 010855 manual

John Adams

John Adams Silly Sausage instructions

E-FLITE

E-FLITE Habu 32 EDF ARF instruction manual

Fisher-Price

Fisher-Price L3244 instructions

marklin

marklin 37735 user manual

Tiger Electronics

Tiger Electronics Alien Blaster 64-008 instructions

Ready 2 Folo

Ready 2 Folo The Party Stadium Assembly instructions