10

ON-DECK MOUNTING INSTRUCTIONS

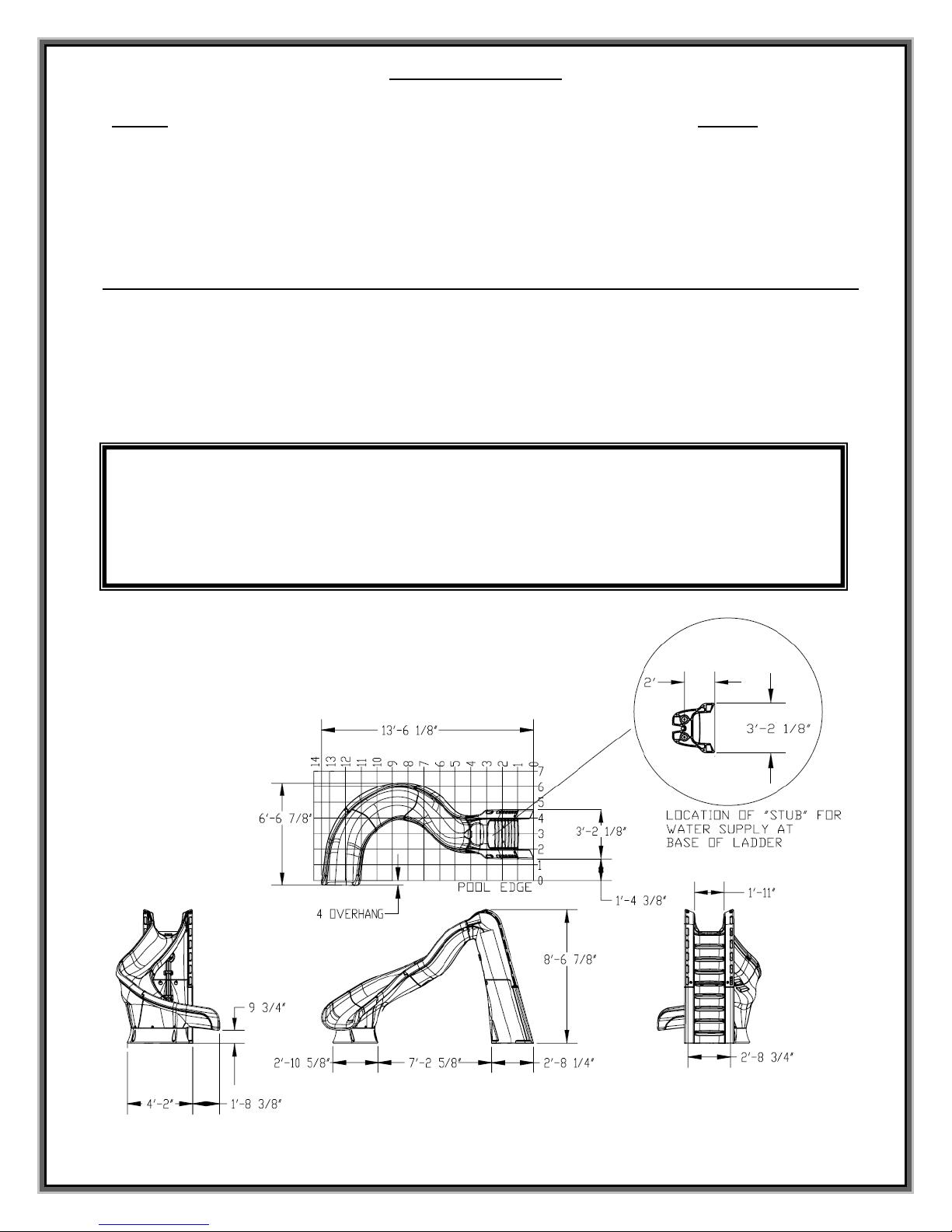

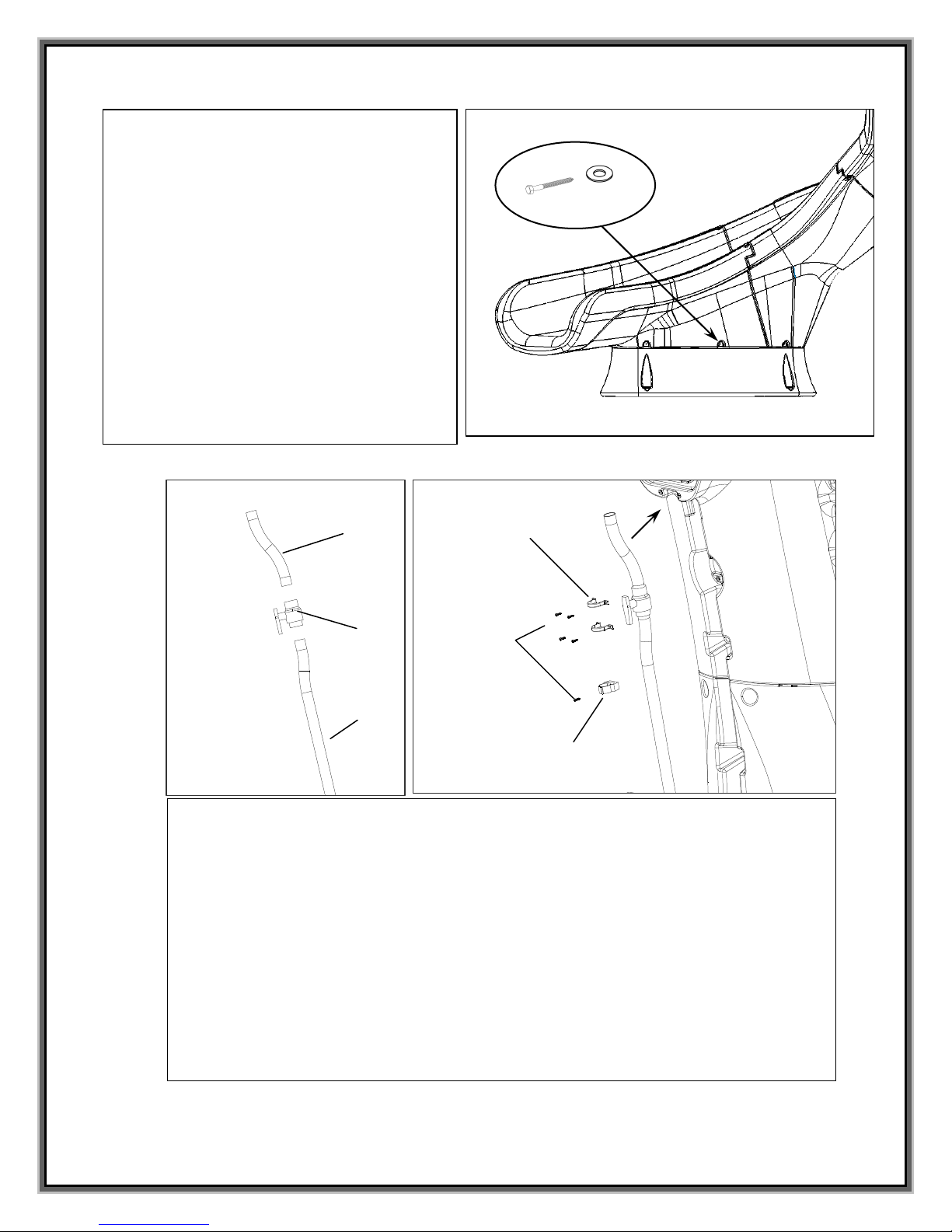

1. Place the assembled slide on the deck relative to the pool wall. Ensure that the exit flume clears

any coping. Slide may be angled slightly providing all dimensions are maintained as noted in the

Manufacturer’s Placement Instructions noted in the following section.

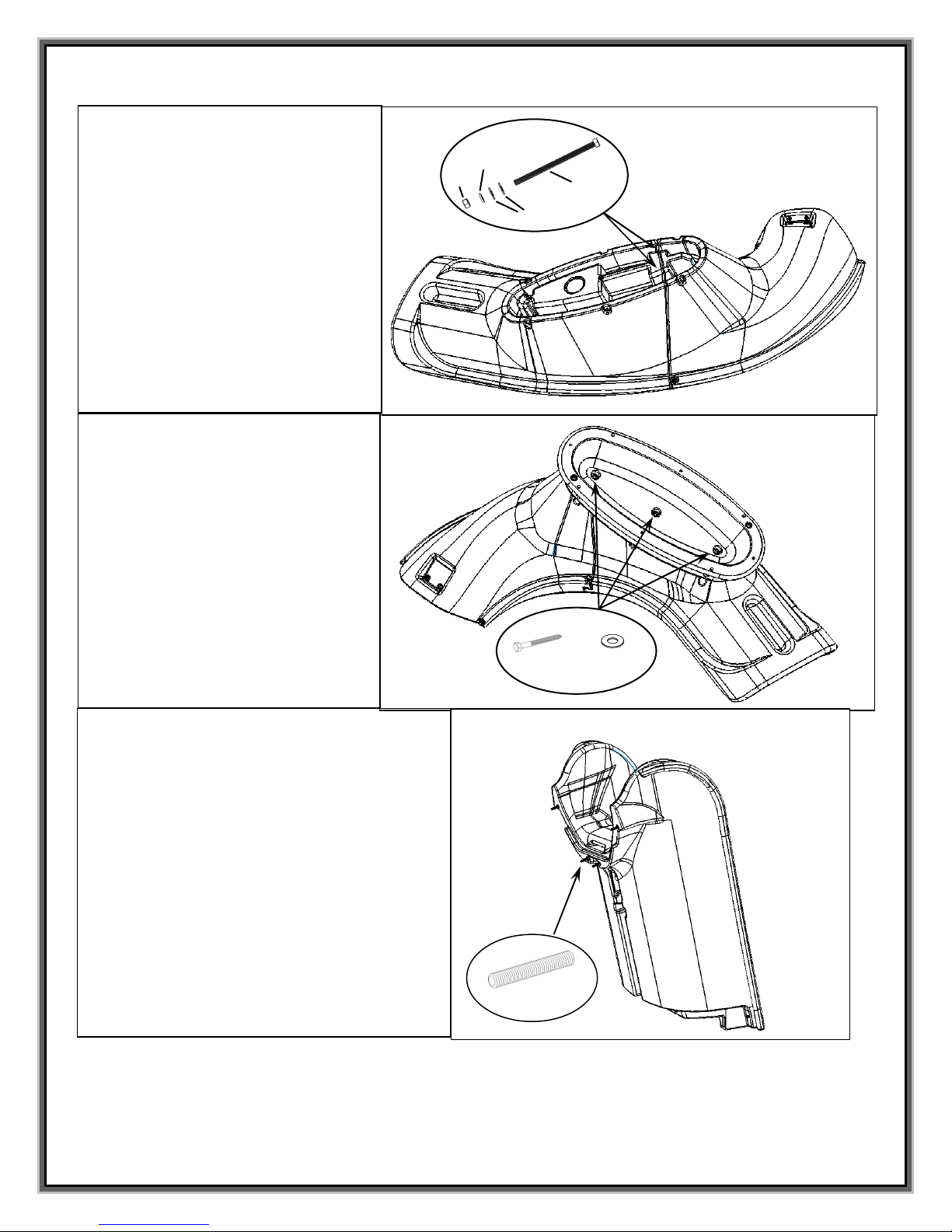

2. With the slide in its proper location, center punch or otherwise mark through the (8) mounting holes

at the bottom of the ladder and pedestal so that a visible mark is apparent on the concrete.

3. Move the assembled slide aside to facilitate drilling of the

anchoring holes.

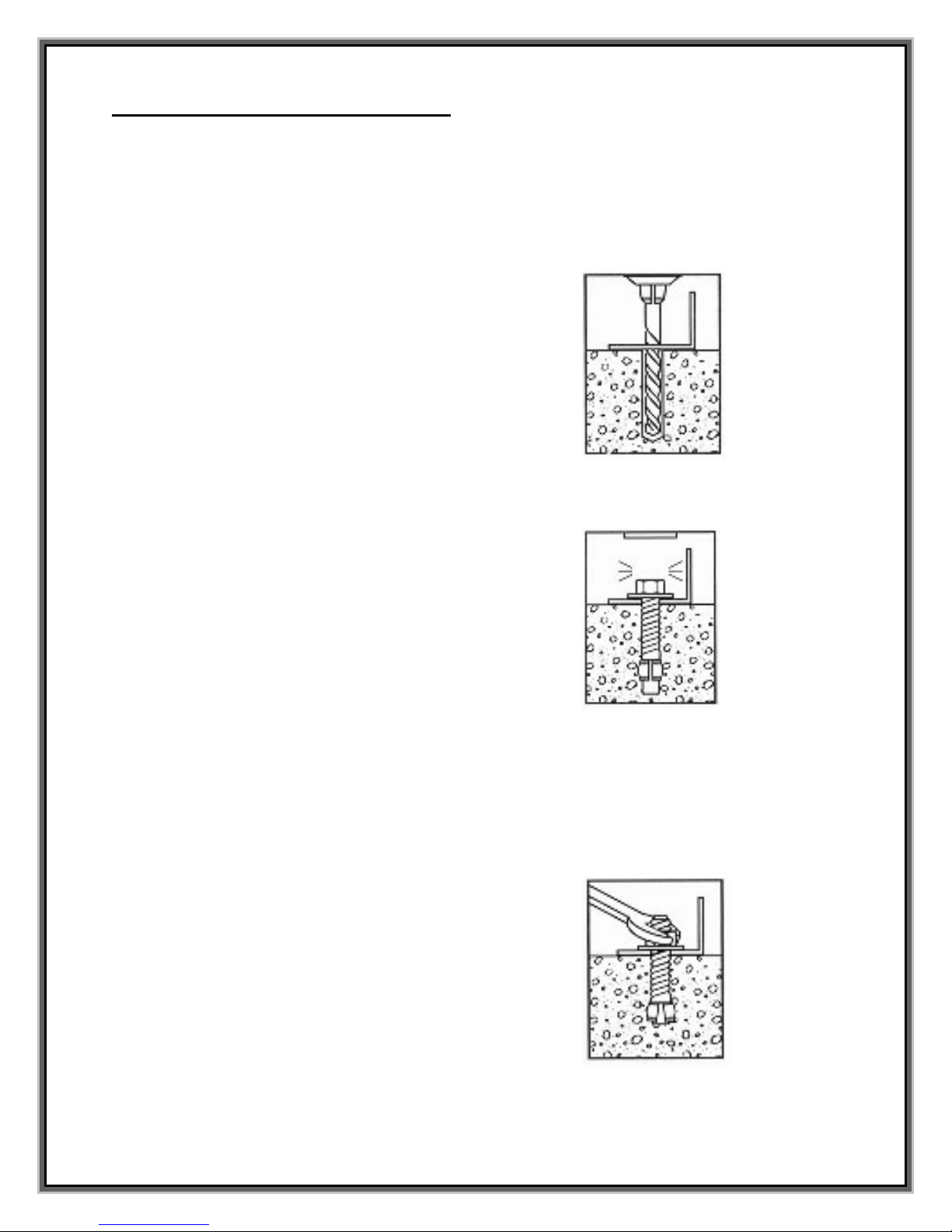

4. Using a power drill and a 1/2” concrete drill bit, drill the holes

to a depth of 4”. Use tape or a marking on the drill bit to

ensure that the hole for the anchor is drilled to the required

depth. Maintain drill hole straight and perpendicular for

proper holding strength of anchor stud.

5. Clear the holes of all debris. Assemble anchor with nut and

washer so that the top of the nut is flush with the top of the

anchor. Move the slide over the holes and insert the

anchors. Drive anchor through the slide mounting holes so

that nut and washer are flush with the surface material.

6. Ensure the slide ladder is plumb by placing a level on a ladder tread. If necessary, shims can be

provided by S.R. Smith to place beneath the base of the ladder to ensure it is plumb due to varying

deck slopes. Please call 1. 800.824.4387 if shims are needed.

7. Expand anchor by tightening nut 3 to 5 turns. Once anchor

is set remove nut and install a lock washer, item # (3), and

retighten nut to a torque of 25 ft.-lbs.