S-Tech SV User manual

P a g e . 1 | 15

TECHNICAL MANUAL

Instructions for installation and commissioning of seismic

valves model: SV

English version

P a g e . 2 | 15

INDE

1.General information and warnings for installer staff (page.3)

2.Prescriptions before installation (pag.4)

3.Safety instruction (Pag.5/6)

4.Instructions for installation, use and maintenance of the valve SV (pag.7/8)

5.Commisioning and maintenance (page.9)

6.Reset and activation of the device (pag.10/11)

7.Information indicated on the product (pag. 12)

8.Declaration of conformity CE (pag. 13)

9.Warranty (pag. 14)

10. Contacts (pag. 15)

P a g e . 3 | 15

Before to proceed to installation, commissioning or

maintenance, operators must:

• Examine the safety provisions applicable to installation which they must operate;

• Obtain the necessary permits to operate when required;

• Adopt the necessary personal protection equipment.

• Ensure that the area in which they operate is equipped both with means of collective

protection provided and the necessary security details; in particular if

the gas used is flammable the surrounding area must be ATE classified.

•In particular, check if the area in which you work is classified for ATE purposes and

corresponding to the product marking (2G = Zone 1)

PRELIMMINARY CHECKS FOR PROPER OPERATION

It is advisable to execute a preliminary verify of product at the time of delivery for detect and report any damage

incurred during transport and handling. In the event of a claim you should contact our technical assistance office.

GENERAL PRODUCT INFORMATION:

-TECH is a trademark owned by Gas Broker srl used for the marking and distribution of seismic valves model V. The

use of gas valves with automatic seismic action with manual reset is recommended, and it is also, in some cases, a

legal obligation, to prevent damage caused by an earthquake from adding other damage due to fire or explosion

caused by the consequent gas leaks.

The valves have been designed to automatically intercept the gas in the event of an earthquake according to the

internationally recognized American standard A CE 25-16 and have been subjected to the CE marking according to

the following European directives:

DIRECTIVE 2014/34 / EU (ATEX) in force since 20/4/2016 concerning the approximation of the laws of the

Member tates relating to equipment and protective systems intended for use in potentially explosive

atmospheres.

DIRECTIVE 99/92 / EC OF THE EUROPEAN PARLIAMENT AND OF THE COUNCIL of 16 December 1999

relating to the minimum requirements for improving the protection of the safety and health of workers who

may be exposed to the risk of explosive atmospheres.

DIRECTIVE 2014/68 / EU (PED) implemented with Legislative Decree 26/2016 for the approximation of the

laws of the Member tates on pressure equipment.

For the purposes of preventing seismic risks and identifying seismic areas, the Presidency of the Council of Ministers

issued on 20 March 2003, ordinance N ° 3274, updated with OPCM 3519/06, which provides that they are used as

reference standards some technical guides attached to the ordinance, drawn up by experts in the sector.

ome data on seismic risk can also be obtained from the civil protection site:

https://rischi.protezionecivile.gov.it/it/sismico/attivita/classificazione-sismica

Once your seismic area has been identified, even if there is no legal obligation (... service systems above 50 m3 / h

must be equipped with valves for the automatic interruption of the gas supply...), therefore also for systems with a

flow rate of less than 50 m3 / h including domestic, it is recommended to install the seismic valve in order to avoid

further dangerous situations in the event of an earthquake.

V valves have sizes ranging from DN15 up to DN250 with two pressure classes 500mbar and 4bar as prescribed by

the Asce25-16 technical standard and can be installed vertically or horizontally.

For the European market, the product is distributed with the CE marking while for markets in the Americas the valves

are subjected to the C A (U + C) marking; both markings are evaluated by the third Notified Body for compliance

with the Axes 25-16 technical standard.

P a g e . 4 | 15

PRESCRIPTION BEFORE INSTALLATION

The device consists of a valve with a mechanical seismic actuator, with automatic intervention, with manual reset,

which can be installed, depending on the project, in a vertical or horizontal position. In its normal working position,

the valve is armed in the open position and closes automatically by releasing the shutter when the mechanical

seismic actuator detects stresses like those indicated in the Axes 25-16 technical standard.

The V valve is designed for installation upstream of the gas system that develops inside both civil and industrial

buildings or near the regulation and measurement units to protect them or, in any case, to protect the section of the

plant, utilities or equipment located downstream of the V seismic valve in the case of seismic events or catastrophic

damage that can stress the valve like the magnitude of an earthquake (accidental violent shocks, landslides, violent

floods, etc.).

Before proceeding with the assembly, it must be ensured that the V seismic valve to be installed is suitable for the

place in which it will be used both for the presence of an area classified as dangerous for explosion and for the

pressure rating of the piping.

The utmost care must be used during loading, unloading, transport and installation operations in order to safeguard

the integrity of all parts of the V valve.

V valves must always be used within the standard installation conditions provided by the manufacturer.

For the installation of the V valve, the environmental conditions must be taken into account to ensure correct

operation over time. The manual reset element of the valve, the bubble viewer that indicates the correct installation

position and the plate should be easily accessible to operators in charge of operation and maintenance.

Any subsidence / settlement of the ground, corrosion and other risks must be taken into account. The components

used for installation must be suitable for the pressures and temperatures that occur under normal operating

conditions as well as for pressures up to the declared Maximum Operating Pressure. For any arrangements inside

buildings, the fire protection names contained in EN 1775 must be respected.

The installation, use and maintenance of the V valve in a different way from that foreseen by the manufacturer (see

the standard installation conditions and the prescriptions given below) can jeopardize the protection method

adopted due to the risk of explosion (with very serious consequences for safety) and the annulment of the EC

declaration of conformity, thus invalidating the respective responsibilities on the part of the manufacturer.

The same consequence occurs if modifications of any kind are made to the valve or if it is modified or disassembled

having access to the internal parts without authorization or if it is used improperly that does not comply with what is

described in this manual.

However, the possibility of using the V valve in installation conditions other than those indicated is not excluded,

unless verified by the manufacturer, but in any case it can only take place with the specific written authorization of

the manufacturer.

Requirements for technical staff

Installation and maintenance must be carried out by suitably trained personnel with proven experience and in

compliance with the applicable European directives and local regulations and must be carried out by personnel with

the qualifications required by Italian law for installation and maintenance. of plants and equipment that use

combustible gas.

During these activities, personnel not strictly necessary must be removed and the work space must be appropriately

marked, which must highlight the dangerous conditions, prohibitions, behaviors and safety information in

accordance with current workplace safety regulations.

P a g e . 5 | 15

SAFETY INSTRUCTION

SV seismic valves must be used in compliance with the following requirements which are essential for protection

against the risk of explosion.

Before starting the installation, in agreement with the customer's safety managers, it must be ensured that there is

no explosive atmosphere in the area. This situation must be guaranteed for the entire duration of the installation and

blank testing operations until the valve is put into operation.

The V model seismic gas valve is a device whose safety is provided for use in hazardous areas classified as surface

for group IIB gas (propane, methane, etc…).

The ATE installation category is 2G (Zone 1, 2) and compliance with the EH R (Essential Health and afety

Requirements) of the ATEX Directive is guaranteed in accordance with EN I O 80079-36 and EN I O 80079-37

Electrostatic discharges

This device is also suitable for installation in a potentially explosive area in accordance with the previous paragraph. In

this area, the sparks produced by electrostatic discharges could generate explosions. Although during normal operation

there are no potential hazards on the appliance, during installation / maintenance activities we recommend the use of

dissipative footwear and a damp cloth (ρ%> 65%).

Equipotential bonding

Inside buildings, all metal parts that make up the installation of the seismic valve, if they can be the site of electrostatic

charges, must be tied and connected to a ground wire in accordance with EN 1775. Care should be taken to avoid

interactions between this equipotential bonding and a cathodic corrosion protection system.

Indications provided for marking

This device is designed to meet the protection requirements according to the marking affixed by the manufacturer:

II 2G Ex h IIB T4 Gb, the temperature range of use, environment and fluid, are between -23 ° / + 66 ° C.

Description of symbols relating to intrinsic safety

TÜV IT 22 ATE 029 AR Atex deposit certificate number

CE: product compliant with applicable European Directives

0918 identification code of Notification Body (TUV)

Etex brand: indicates a product compliant with installation in a hazardous area

II Gruup II: surface installation

2G Category 2 product (zone 1) for gases, fumes, vapors

Ex h Type of protection adopted

IIB Group of gases considered (propane, ethylene, natural gas)

T4 Temperature class

Tamb: -25°C ~ +66°C Temperature for the use of the valve within which the safety of use is

guaranteed

ATTENTION!

BEFORE PROCEEDING WITH THE INSTALLATION, IT IS RECOMMENDED TO CAREFULLY READ

AND CHECK THE FOLLOWING INSTRUCTIONS IN THIS MANUAL.

P a g e . 6 | 15

Installation near regulation and measurement groups

If the V valve is installed in the immediate vicinity of regulation and measurement groups and / or is incorporated in the

same protection cabin / cabinet, all the precautions and design and safety requirements provided for by the EN 12279

and EN 12186 standards must be respected. particularly for the phases of first start-up, normal operating conditions,

decommissioning and restarting of the system.

Requirements according to points 6.1, 6.2 and 6.3 of the EN 12186 standard

6.1 Gas pressure regulating stations must be designed, constructed, positioned, operated and maintained taking into

account the safety and environmental requirements of the applicable regulations.

During the initial planning phase of the station, careful consideration must be given to the configuration of the site,

the need for security of the site and the possible housing of the installation.

Locations susceptible to impact damage should be avoided, or adequate precautions must be taken to prevent them.

6.2 The area of the site must be adequate to house the equipment ……,… taking into consideration the safety

distance required by the regulations.

…… ..The need to provide emergency exits must be taken into consideration and, where appropriate, these must be

installed.

The extent of the hazardous areas must be determined ……… and taken into account when defining the site's battery

limits.

6.3 ite ecurity

The gas pressure regulation stations must be secured against the entry of unauthorized persons.

If using a site safety fence, the equipment should be placed far enough away from the fence to prevent outside

interference.

In an area subject to greater risk of interference, an adequate number of security inspections for the station or the

use of anti-intrusion devices must be considered.

Clearly visible signs prohibiting smoking and other sources of ignition must be displayed. The entrances to hazardous

areas must be marked according to national regulations.

igns indicating an emergency telephone number must be clearly displayed.

P a g e . 7 | 15

ISTRUCTION FOR INSTALLATION, USE AND MAINTENACE OF THE SEISMIC VALVE SV

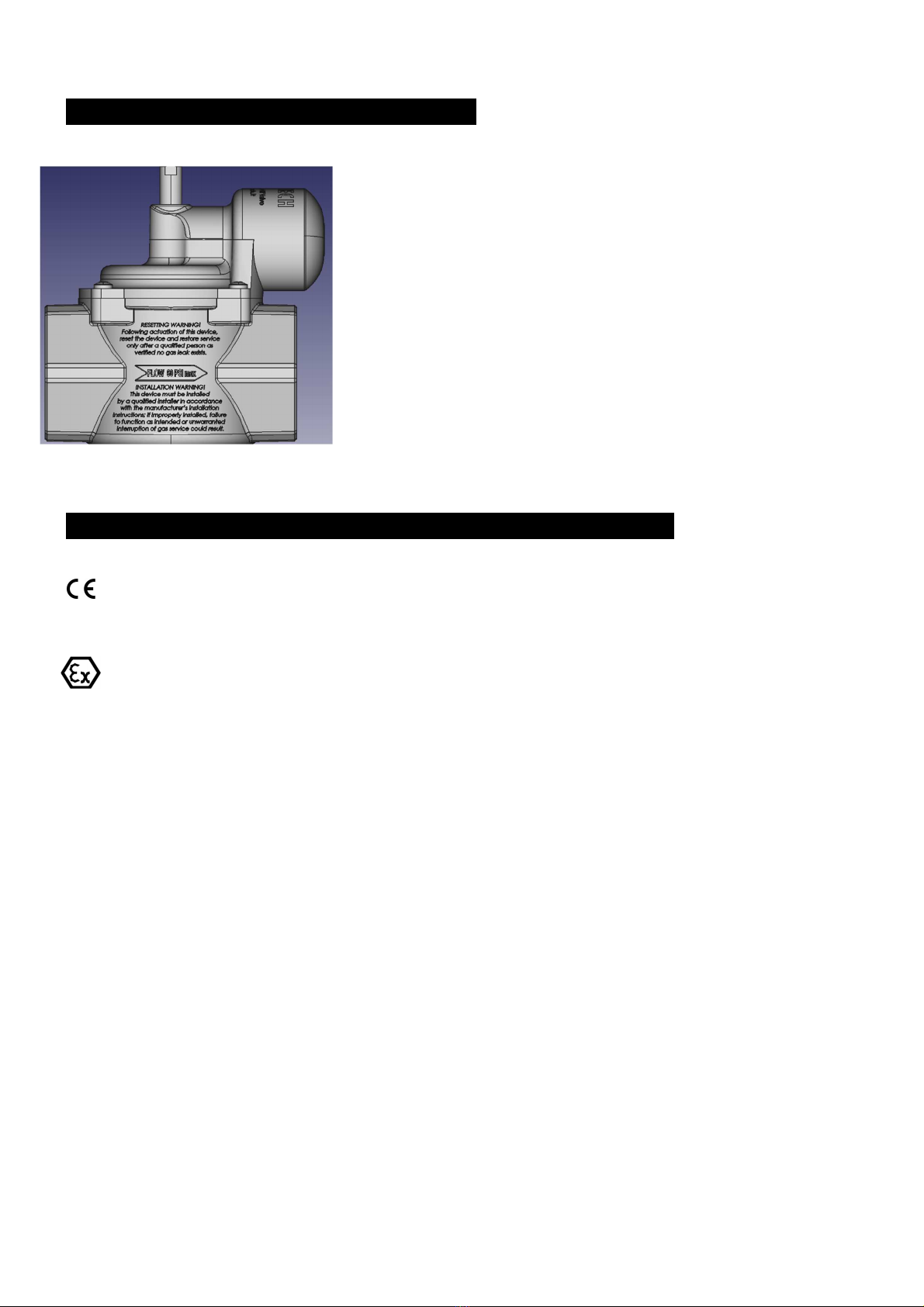

The SV valve incorporates a bubble viewer as in the spirit levels, to indicate its correct positioning and

consequently its operation; if the valve is installed correctly, the bubble must be positioned in the center of the

viewer, present above the sensitive organ, as shown in the image below:

Further illustrative example:

P a g e . 8 | 15

During the installation you must perform the following operations:

•The installation must be carried out by adequately trained personnel;

•

Verify exactly the correspondence of data reported on the label with your

requirements

;

•Verify that the installation is carried out according to laws in force and

according to the rules of good practice in the use of LPG and Natural Gas;

•Make sure that the valve chosen is suitable for the maximum operating

pressure and for the classified area declared in the Atex marking;

•The mechanical installation must be made so that in subsequent operation

the V seismic valve itself is not subjected to vibrations, abnormal

temperatures, stray currents or currents due to cathodic protection devices;

•Check the available space, that the dimensions are adequate for the intended installation area depending on its

horizontal or vertical installation as they have different dimensions depending on the type and that the assembly

allows any maintenance of the product itself; (If the space is insufficient (meter mounted in a box or niche in the

wall) or it is not possible to interrupt the piping, the valve can be mounted anywhere on the line before entering

the house.

•Make sure that the upstream and downstream shut-off valves are closed;

•top the flow of gas by closing the inlet valve located before the meter;

•After checking the condition of the pipe, that it is not damaged by corrosion, (otherwise replaced) proceed by

cutting it to size and threading the ends;

•Before fixing it on the piping, carry out an intervention test by arming the valve (see instructions on page 9) in a

horizontal or vertical position according to the model and shaking it slowly

until the activation of the operation audible by the metallic noise

produced by the closing of the shutter;

•Make sure that the fluid passing through the valve is suitably filtered and

therefore cleaned, if necessary, install a suitable filter upstream of the

seismic valve capable of retaining any impurities present in the fluid

passage;

•Check that the upstream and downstream pipes are aligned and centered

correctly, fixed integrally with the wall by means of special wall fixing

collars, making sure that they are able to support the weight of the

seismic valve without transmitting bending-torsional stresses to the valve

body itself;

•Check that there is parallelism between the product connections with

the pipes before and after the seismic valve in such a way as to make the

pipe / valve assembly integral with the wall where it is installed, so that the stresses of the wall in the event of

an earthquake are also transmitted to the valve;

•Check that the pipe has been cleaned of any impurities and that it does not contain dirt, welding residues, slag

and paint residues;

•• Check the correct position of the valve by making sure that the bubble indicator in the upper part of the

sensitive element of the valve shows the bubble in the center (this indicates that the ball inside it is perfectly

seated in the seat of the sensitive element and the product can function properly);

•Make sure the seismic valve is installed on the line with the arrow on the body in the same direction as the gas

flow.

P a g e . 9 | 15

COMMISIONING

For installation on the methane gas distribution network, the risk of formation of explosive mixtures (gas / air) inside

the pipes must also be considered. After installation, check that the inlet and outlet on-off valves, any by-pass and

the relief valve are all closed. Before proceeding with commissioning, it is recommended to check the external

tightness of the system, checking for any gas leaks / leaks. In the event of a gas leak, using a soapy solution, bubbles

or swellings will form. Although the devices are delivered prepared from the factory, it is possible that these values

may undergo possible deviations during transport (due to vibrations, etc.), it is therefore advisable to check the

settings according to the procedures listed below.

During commissioning, the risks associated with any discharges into the atmosphere of flammable or noxious gases

from sources other than the valve itself must be assessed.

During commissioning, the following steps must be carried out:

It is recommended to operate the opening and closing valves very slowly because too

rapid maneuvers could damage the seismic valve.

1. Commissioning must be carried out by suitably trained personnel.

2. After all safety checks, slowly open the upstream shut-off valve until pressure

stabilization is achieved;

3. After completing the hydraulic connections, carry out the required tests to check the

tightness of the discontinuity points of the gas circuit.

4. Once the product installation is complete, proceed with the reset. ( ee page 9 for reset

instructions).

5. Once the seismic valve has been armed, replace the pin covering the reset stem

correctly screwed backwards on the body of the device. (In this way the reset stem of

the device is protected from deterioration of the rubber seals due to the deposit of

dust, water and / or other corrosive agents, extending the useful life of the device).

6. lowly open the downstream on-off valve until pressure stabilization is reached and

carry out the safety checks relating to the valve outlet seal;

7. Having checked that there are no gas leaks, the valve remains in operation armed for its purpose.

8. It is of fundamental importance that the valve remains mounted correctly with the bubble viewer in the correct

position, verifying over time any deviations due to subsidence of the ground.

9. If the valve is installed improperly, it could cause the failure or intentional or unjustified interruption of the

gas supply service

.

MAINTENACE

A specific periodic maintenance of the device is not necessary if correctly installed and if corrosive gases are not

used.

P a g e . 10 | 15

RESET AND DEVICE ACTIVATION

Please inform the competent authorities in case the device is activated following an earthquake.

Before proceeding with the reset, you must check that there are no gas leaks.

Procedure for resetting, see the images below

:

P a g e . 11 | 15

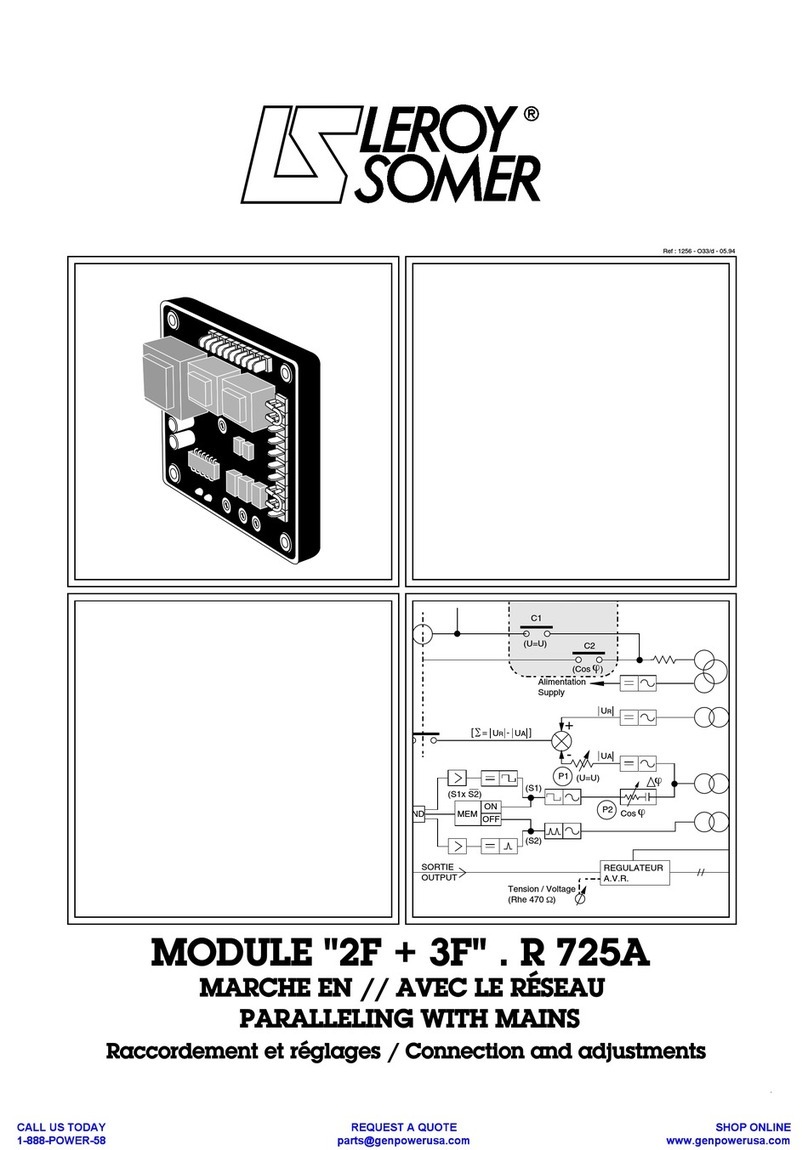

-Figure 1 shows how the product will be delivered (seismic valve and pin in the same packaging but separate).

-Figure 2 shows how the pin is screwed into the stem to proceed with the reset.

-Figure 3 shows how the reset is activated by pulling the pin screwed onto the reset stem.

-Figure 4 shows the direction to reposition the pin.

-

Figure 5 demonstrates how the pin must be repositioned correctly in order to protect the device In this way, the reset

stem of the device is protected from deterioration of the rubber seals due to the deposit of dust, water and / or other

corrosive agents, prolonging the useful life of the device

.

GENERAL INFORMATION INDICATED IN THE PRODUCT

The plate shows

• the identification data of the single valve (code, connections, year of production);

• the data relating to the parameters for use in an area classified for Atex purposes and their symbols;

• reports information about the installation position and the pressure and temperature limits;

• the CE marking and the identification number of the Notified Body;

• name or trademark identification of the manufacturer.

Example of label:

P a g e . 12 | 15

WARNINGS / INDICATIONS ON THE PRODUCT

ATTENTION! This device must be installed by a qualified technician according to the

regulations in force; if installed improperly, it could cause non-functioning such as

intentional or unjustified interruption of the gas supply service.

FLOW / ARROW = the seismic valve must be installed respecting the flow direction

indicated by the line with the arrow on the body, paying attention to the maximum

operating pressure.

Notice for recovery:

ATTENTION! Following activation of the device, it can only be reset after a qualified

technician has checked that there are no gas leaks.

LIST OF SYMBOLS USED IN THE PRODUCT AND IN THE CERTIFICATES

= compliance with applicable European Directives

0918 = Notification Body (TUV) identification code

= indicates a product compliant with installation in a hazardous area, for further Atex indications

check page 5

TS: -25°C ~ +66°C = Temperature range within which compliance and intrinsic safety is guaranteed

S.N.= erial number

DN = size connections

P. Max = Maximum working pressure

Position = Working position (that can be horizontal and vertical)

YEAR = production year

It is possible to consult the technical data of the valve in the body of the product itself,

and in the packaging label.

P a g e . 13 | 15

E AMPLE OF DECLARATION OF CONFORMITY

P a g e . 14 | 15

WARRANTY AND COMPLAINTS

-TECH / Gas Broker rl guarantees the conformity of the products supplied, guaranteeing that they correspond in

quality and type to what is established in the order confirmation and that they are free from defects that could

make them unsuitable for their intended use, on condition that correct installation has been carried out according

to the instructions in this manual and that corrosive gases are not used.

The V valve is maintenance-free and for no reason must it be disassembled by accessing the internal parts; the

assembly of the screws on the valve body is done in such a way that there is evidence of any disassembly, in

the case of attempts to disassemble the warranty automatically lapses.

-TECH makes no further warranties for this product

Validity of the guarantee: 3 years, starting from the date of purchase of the product.

The buyer is required to verify the correspondence between the products indicated in the transport document and

the products delivered and any complaints must be made by the Buyer within a short timeframe from the moment

in which the products arrive at the place of destination and in any case, under penalty forfeiture, no later than 15

days from that moment.

The warranty for defects is limited only to product defects resulting from design, material or construction defects

attributable to Gas Broker .r.l., and does not apply in the event that the Purchaser cannot prove that he has made

a correct use and installation by qualified personnel, proper storage of the products and not having modified or

repaired them without the seller's consent.

Any complaints must be made in writing and must indicate in detail the defects or non-conformities contested. Any

return must be previously authorized by Gas Broker srl. Following a regular complaint by the Buyer, made pursuant

to this article, Gas Broker s.r.l., at its choice, may:

supply free of charge, ex works, to the Buyer products of the same type and quality as those found to be defective

or not conforming to what has been agreed;

credit the Buyer a sum of money equal to the value of the products found to be defective or non-compliant.

If it is verified that the complaint is unfounded or the product is damaged and / or installed not in accordance with

the provisions of this manual, the Buyer will be required to compensate Gas Broker s.r.l. all costs incurred for the

assessment including, by way of example, the analysis of the complaint, control, testing and inspection.

The warranty starts from the date of purchase of the product; to obtain the warranty service if the product is

malfunctioning, Gas Broker srl must be notified within the warranty coverage period, presenting the relative

purchase invoice.

Limitation of Liability

The responsibility of Gas Broker s.r.l. is limited only to the value of the product supplied and according to the

warranty conditions specified above with the exclusion of any liability and claims for compensation for any damage

that may arise to people or things.

In any case, notwithstanding the provisions of articles 1578 et seq. c.c., Gas Broker s.r.l. is not liable for direct,

indirect or otherwise suffered by the buyer or third parties due to the use or non-use of the products supplied.

Under no circumstances will Gas Broker srl be liable for any incidental, special or consequential damages,

personal injury, property damage, damage due to non-use, business interruption, loss of profits or loss of

goodwill, costs associated with the replacement of the seismic valve, removal or installation costs.

P a g e . 15 | 15

This manual is subject to copyright and intellectual property laws, the terms of which must be observed and

followed. The information given in this manual could contain technical inaccuracies or typographical errors.

The information contained therein may be changed or updated without notice, just as Gas Broker srl may

make improvements and / or modifications to the products and / or manuals described at any time without

notice.

Contacts

GAS BROKER srl - S-TECH

Via Villa del Bosco 18,

35037 – Teolo (PD) – Italy

Phone: +39 0495460876

Mobile/WhatsApp: +39 3428630227

Technical assistance: tecnico@s-tech.it

www.s-tech.it

it is a trade mark of Gas Broker srl

The following manual is subject to the intellectual property of Gas Broker srl and cannot be reproduced or copied.

Rev 18 07 2022

S-TECH / Gas Broker Srl reserves the right to make changes and updates to these

instruction manuals without prior notice.

Table of contents

Popular Control Unit manuals by other brands

Acrel

Acrel ASL100 Series instructions

Pilz

Pilz mc1p coated operating instructions

Carel

Carel pGD Touch Series quick start guide

Staubli

Staubli CombiTac direqt Assembly instructions

Leroy-Somer

Leroy-Somer R 725A Connection and Adjustments

VAT

VAT 61228-KAGG-0002 Installation, operating, & maintenance instructions

Speck

Speck UL50/1000Dr operating instructions

ELCOS

ELCOS CAM-335 user manual

CommScope

CommScope CMOD installation instructions

Victaulic

Victaulic FireLock 758-LPA Series Installation, Maintenance, & Testing Manual

KLINGER

KLINGER INTEC K210-FS Assembly and Repair Instructions

Nibe

Nibe SMO 20 Installer manual