2 | Installation manual SAFETRON SL620

The safety features of this product are crucial for its compliance with EN 14846:2008. Modifications or other changes to the instal-

lation and/or products beyond those described in this documentation are not permitted. SAFETRON assumes no responsibility

for products that have not been installed in accordance with the current instructions or if the maintenance instructions are not

followed.

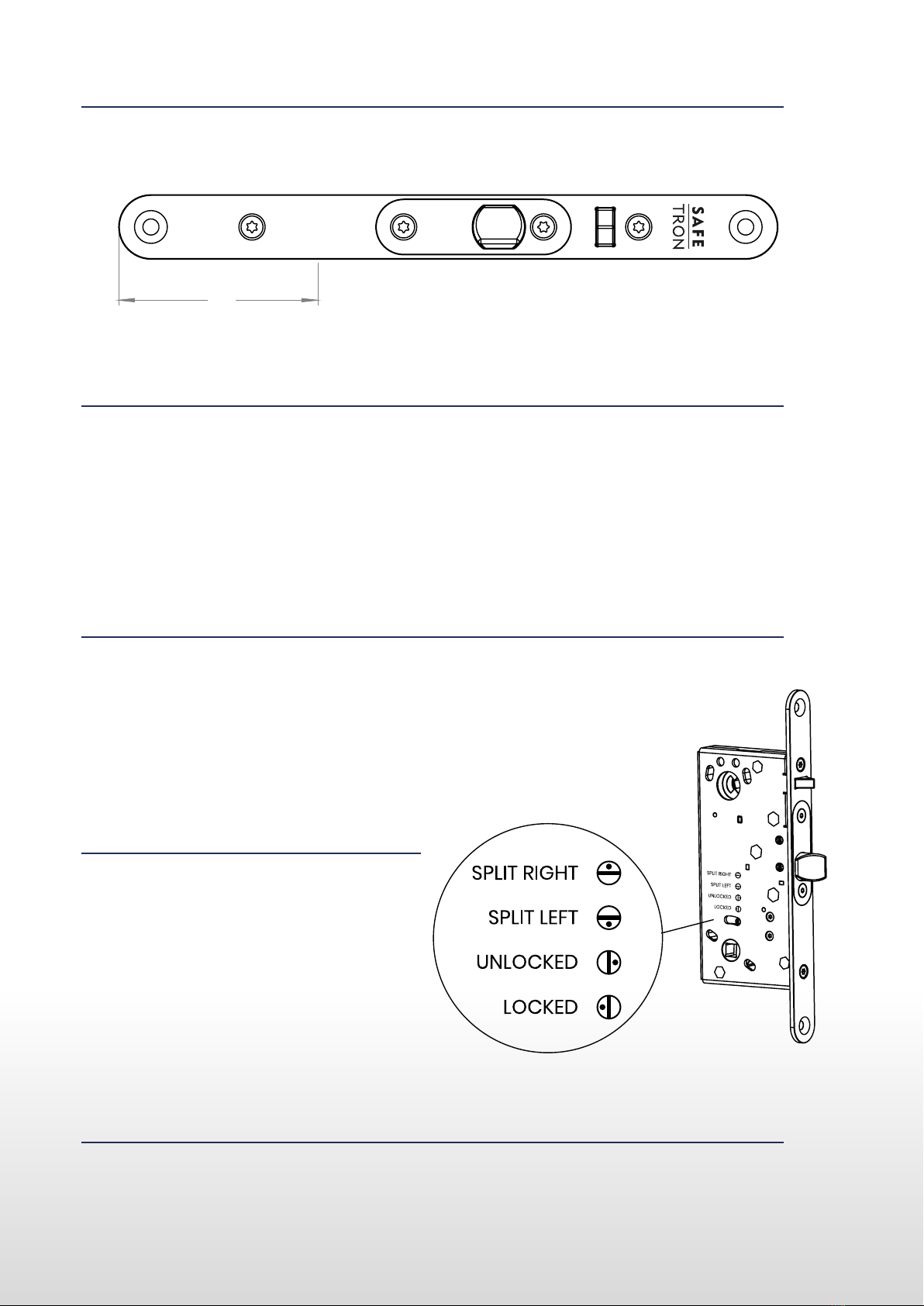

• SAFETRON solenoid locks in the 600 series are electric locks used in doors with normal security requirements. The locks are

available in different designs for different types of usage and security requirements. Solenoid locks are suitable where fast

locking is required and can be used on both light interior doors and heavy exterior doors.

• Fire door rating with reference to test report number: PGA11645A_rev1. The test was performed with a single steel door.

• When used in fire proof doors solenoid locks in the 600 series must be used in conjunction with a certified door.

• Check the door’s fire certificate, if any, to ensure that there are no conditions in the certificate that exclude or restrict the

use of the SL620/SL621/SL630.

• Before installing an electric lock, check that the door is correctly installed and that the door leaf moves freely. It is not

recommended to install SAFETRON solenoid locks in hollow core doors. Check that the door’s construction allows the instal-

lation of a lock, for example by checking hidden hinges, that overlapping doors can be opened at the same time, that the

door gap is 3 mm +/- 1 mm and that moving parts do not affect each other.

• SAFETRON locks may be installed in single doors or double doors made of wood, steel or aluminium. Door weight: over

200kg.

• Locks manufactured according to SS-EN 14846:2008 provide a high degree of reasonable security provided they are fitted to

doors and frames in good condition.

• Consideration must be taken to ensure that any seals or sealing strips do not inhibit the function of the lock.

• Ensure that the correct lock is fitted for the intended door environment (see product catalogue).

• The assembly method does not differ between different types of doors, such as wood/metal.

• Established instructions must be followed carefully during installation. These instructions must be transmitted by the

installer to the user.

• All components specified for the installation must be used to meet the European standard SS-EN 14846:2008.

• Check that the lock latches (when in retracted position) do not prevent the opening and closing function of the door (see

maintenance instructions).

• Where locks are mounted on double doors (double doors) it is required that door closers are used that have a door

coordinator according to EN 1158 (see standard) to ensure the correct closing sequence.

• The products must not be used in doors that can be opened in both directions, such as swing doors.

Read through and follow the installation instructions.

• To ensure a good function, the door gap must be 3mm +/- 1mm.

• Avoid file and emery chips. After the recess has been made in the frame, it must be cleaned properly.

• Ensure that the cable is not pinched or damaged during installation.

• Cable of type data/signal with area less than 0.2 may not be used to supply power to the lock.

• Cable area must be dimensioned based on the conditions that apply.

• When suppling multiple locks/passage systems/readers/central units together the total power consumption must be taken

into account when calculating the cable area.

• The warranty is void in the event of incorrect installation or the use of accessories that are not recommended by

• SAFETRON.

• SAFETRON does not provide a warranty for installations that do not follow the recommendations.

Lock maintenance should be performed by a trained professional. In normal use, the mechanical parts of the lock housing

should be lubricated once a year. Use a lubricant that does not contain graphite or solvents.

• Check that mounted knobs, door handles and cylinders are working satisfactorily. If necessary, lubricate and/or adjust.

• For high-frequency use, the mechanical parts of the lock housing are lubricated as needed.

• The electrical parts of the lock housing are maintenance-free

• Check and adjust if necessary that the door closes correctly. To achieve this, e.g. door hinges as well as door closers need to

be adjusted. A poor door function negatively affects the locking function.

IMPORTANT INFORMATION

INSTALLATION

MAINTENANCE