Note clock is a 24 hour clock. Make sure AM and PM are correct.

Start-Up

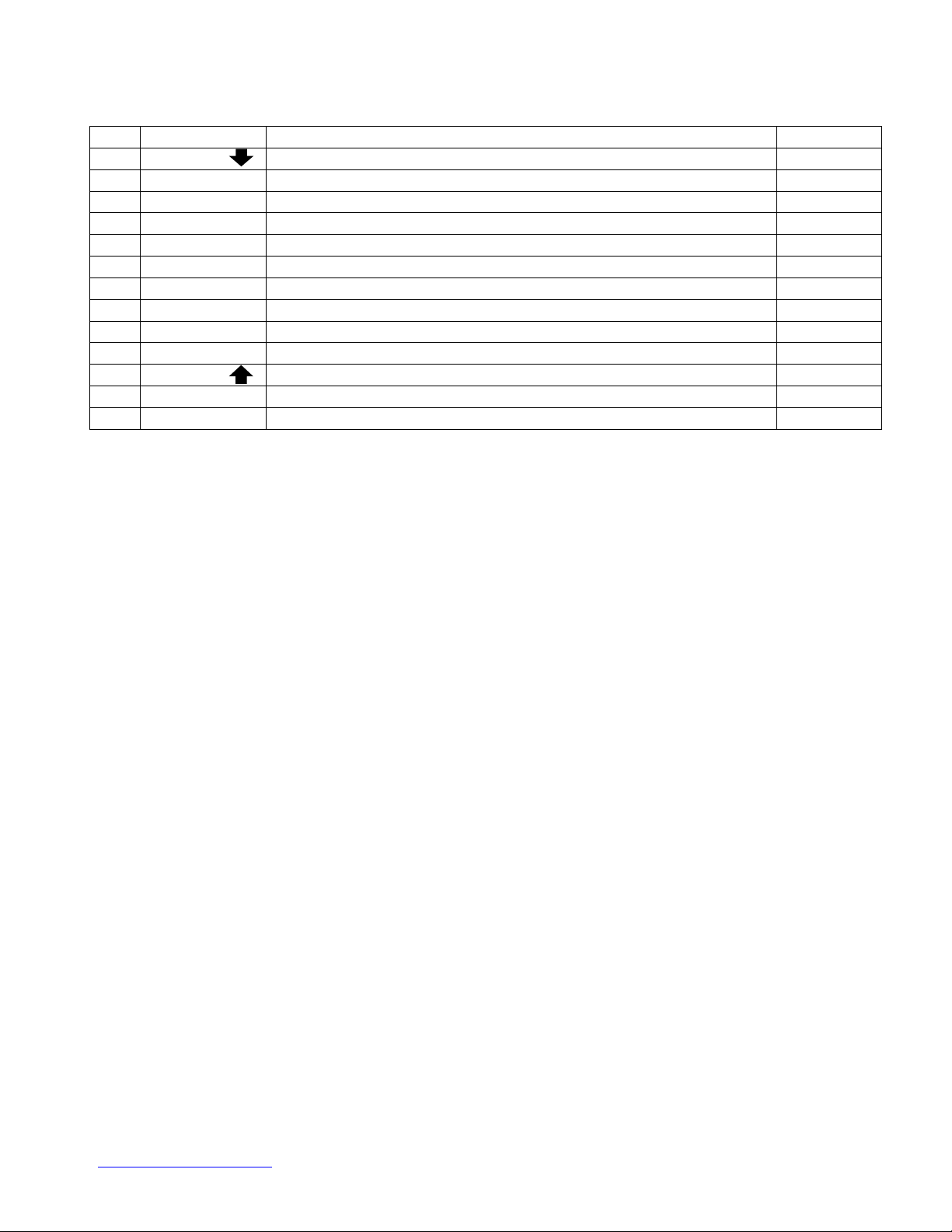

With the valve’s inlet and outlet closed, initiate a manual regeneration and follow these directions:

1. Press REGEN button and hold button for 3-5 seconds for immediate regen.

2. Let the valve advance to BACKWASH.

3. Open valve’s inlet slowly 1/3 to fill mineral tank.

4. Allow air to escape (listen until spurting stops).

5. When water flows from drain, open inlet valve fully.

6. Make sure drain line is not restricted. (Note: Do not “tee”drain line with a softener.)

7. Continue backwash until water runs clear.

8. Press and release REGEN to advance to the DRAW cycle (to create an air pocket in the filter tank.

9. Press and release REGEN to advance to the 2nd backwash. (It should be turned “OFF”.)

10. Press and release REGEN to advance to RINSE. (It should be turned “OFF”.)

11. Press and release REGEN to advance to Refill. (Salt should be set at “ZERO”).

Finally . . .

1. Open the valve’s outlet to supply water to the house.

2. Go in the house and open a faucet. See if water runs clear.

3. Look for “gallons flow” (blinking)

4. Go back in the house and shut off faucet.

Customer orientation

It is important to provide customers with an initial orientation. This should include how to reset the clock and how the

backwashing process works.

Caution

Do not fill swimming pools with water from an Iron / sulfur filter. This will exceed the capacity of the system.

Warranty

Signature Series Safety Zone Water Systems come with a limited warranty. Five years for valves, and ten years for tanks.

Resin, activated carbon and filter media come with a quality guarantee only. See warranty card or go to

www.safetyzonewater.com for full details.