Quantum™ MT™ Installation Instructions Pg. 8 of 8

© SAFLOK™ INS_QTMCARDMT 2/16/2012

SAFLOK Door Unit Inspection Criteria

Appearance

•Finish is free of blemishes or scratches that would distract from lock appearance

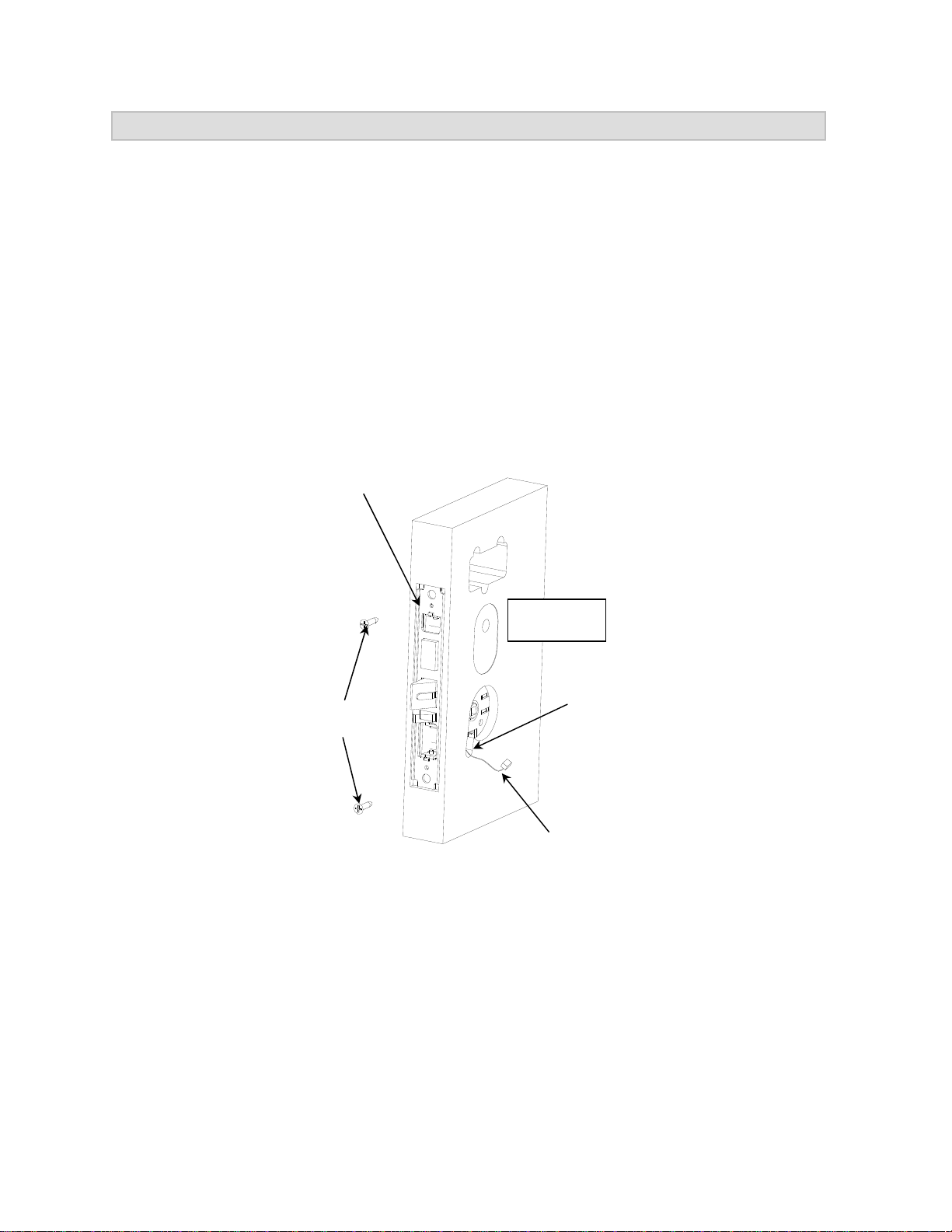

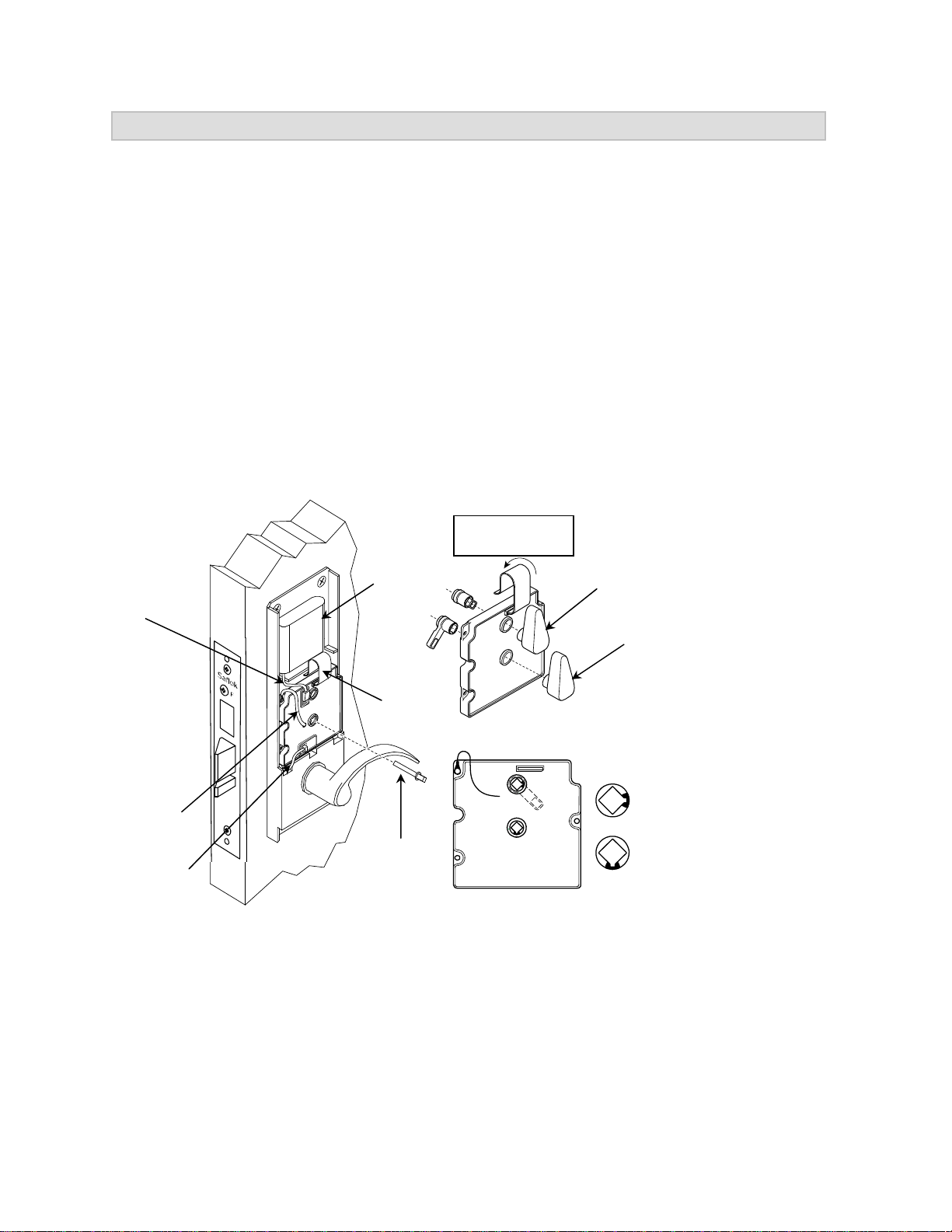

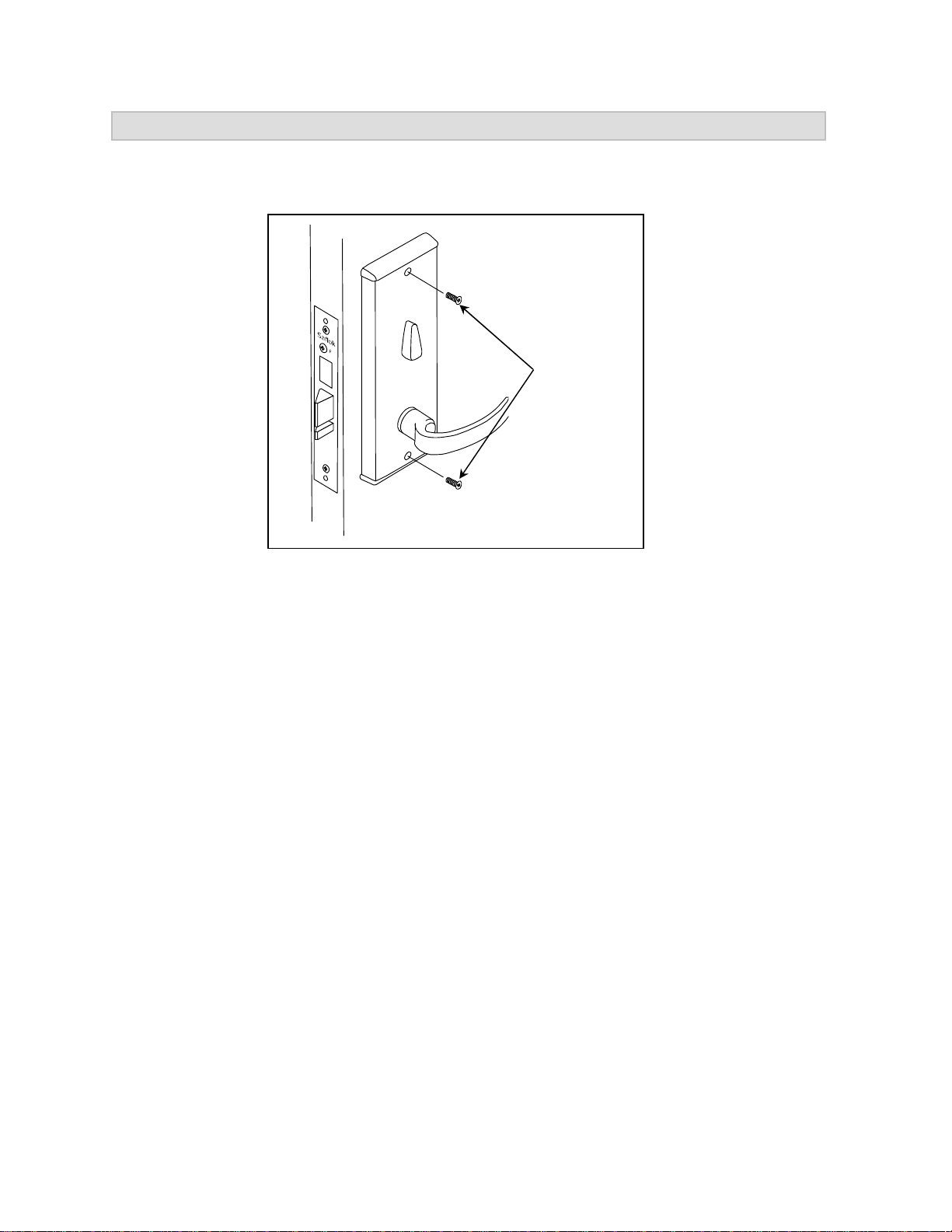

•Lock body and under plate (if used) are mounted straight on the door

•Door scalp is mounted straight and flush with the door edge

•Jamb strike is mounted straight and is flush with the jamb face

•Correction of minor blemishes on the door jamb are the responsibility of the property’s maintenance

department

Lock Function

•Knob or lever rotates and moves freely

•Lever is horizontal to floor when at rest position

•Dead bolt extends fully and retracts without binding (door open)

•Lock latch and dead bolt engage jamb strike plate freely

•Anti-pick latch when depressed (door open)

•Anti-pick latch is depressed when contact is made with the strike plate (door closed)

Electronics/Keycards

•Keycard can be inserted and withdrawn freely

•Yellow light flashes twice when incorrect keycard is used

•Red light flashes twice if keycard is used incorrectly and cannot be read

(e.g., a credit card is used)

•Green light flashes when the proper keycard is used

•Green light is flashing when the lever is operated

•Green light continues to flash for a five-second cycle

•Yellow light flashes 12 times when the dead bolt is extended and a guest/hotel

keycard is used

•All keycards function to the specifications of the master plan

Door function

•Door closes and latches with little or no interference

•Dead bolt extends fully through the strike plate without interference (door closed)

•Spacing between door edge and inside door jamb does not exceed 3/16” (door closed)

Note: If bumpers or other seals are added after strike plate installation and causes alignment and latch

problems, it is the property’s responsibility to correct this condition. This note generally applies to new

construction or new door installation.

Questions? Call Customer Service at 800.999.6213 and select option 3.

For online assistance, visit support.saflok.com.