8

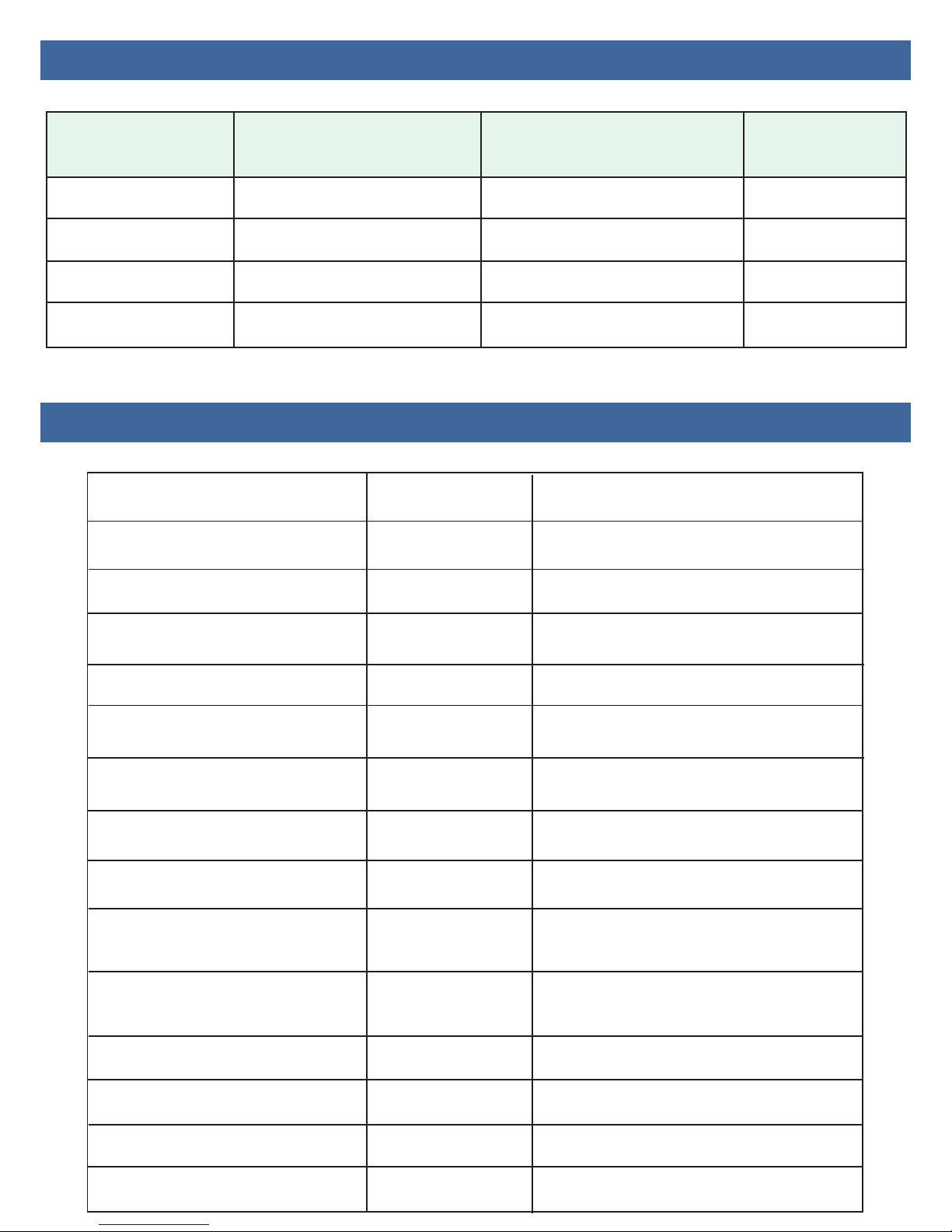

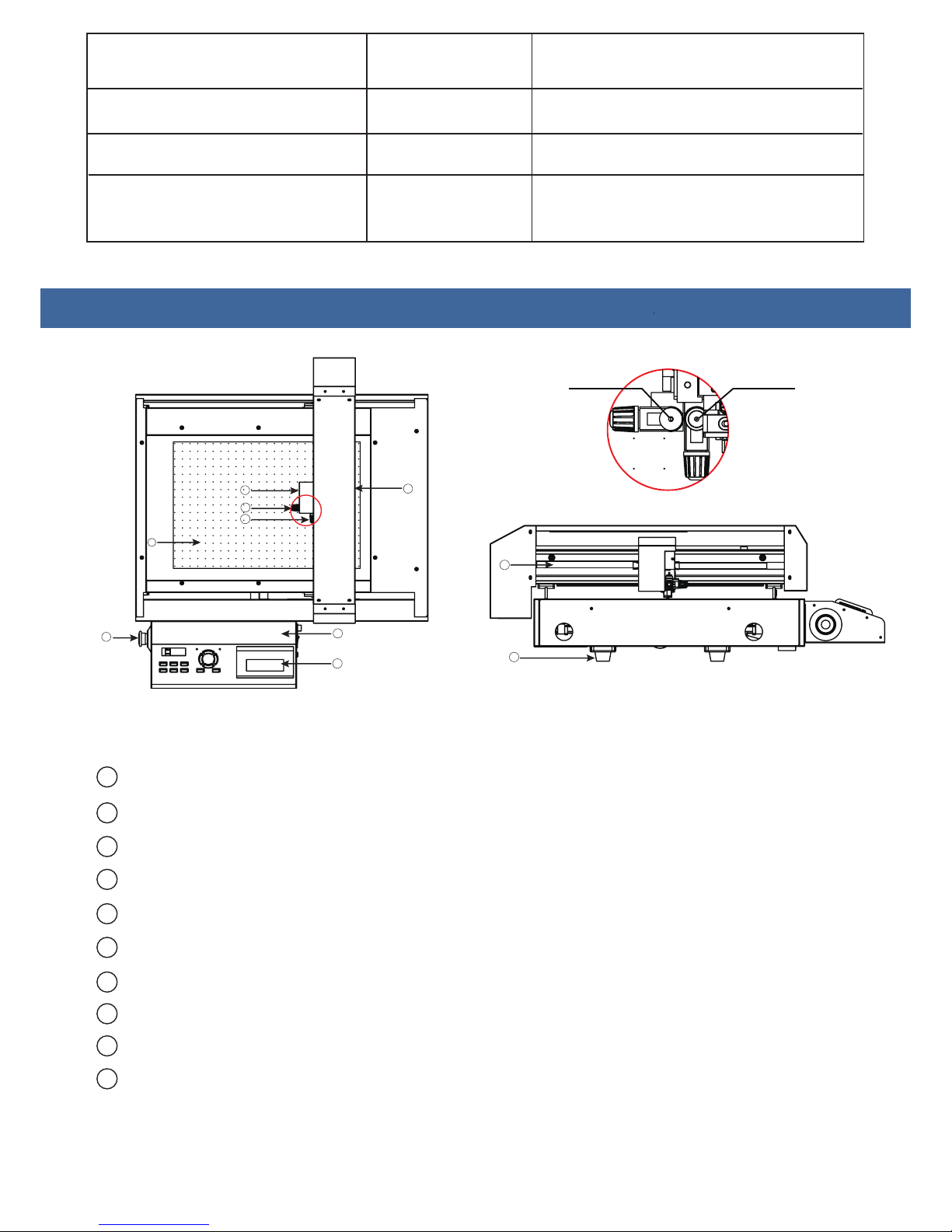

1.4 Control Panel

1

234

5 76

9

11

12

13

10

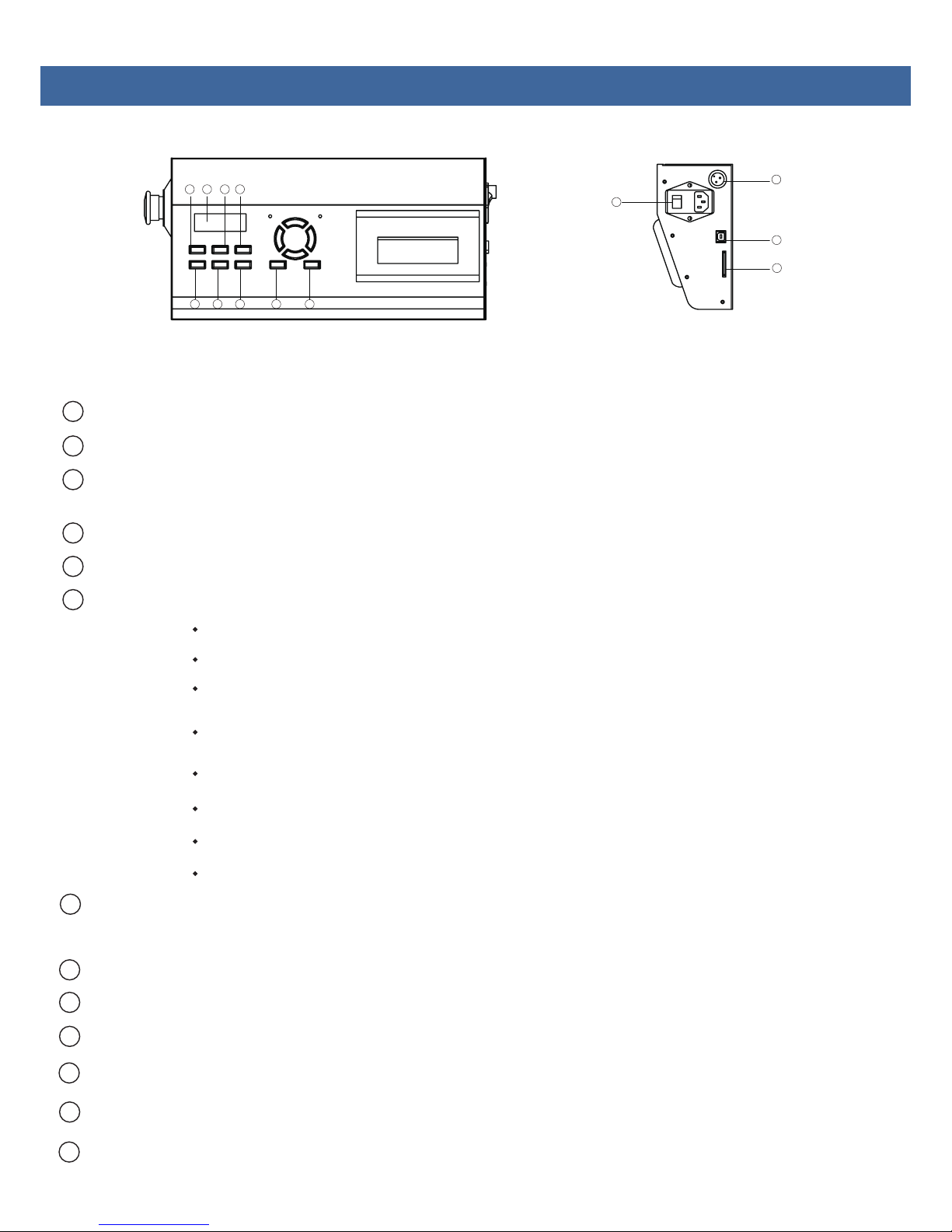

1

LED Display......... Display various parameters.

2Fun1....................The switch for vacuum adsorption function.

3

4

5

6

7

8

9

10

11

12

13

Fun2.................... Return to the main interface, when you set the parameters. Press this key to return to the original interface.

(Original interface display: speed and Force)

Fun3....................The switch for sensor.(the carriage sensor,scan mark)

Reset...................Resrt Key,The carriage will return to the mechanical origin,LED display speed and force.

Set......................Setting machine parameters.

Test.................Runs a cutting test to check whether the currently selected cutting conditions are compatible

with the medium loaded. Usually tool 1 draws a square, and tool 2 cuts a triangle.

Off..................When the speed and Force is displayed, press the off key you can move the carriage and the beam.

Enter...............After setting a function or condition at the control panel, press the [ENTER] key to register your setting.

Power switch..............................Controls the on/off status of the power supply to the cutter.

Air pump jack..............................The jack for connecting main board and air pump

USB interface connector.............Used to connect the cutter to a computer via the USB interface.

SDcard interface connector......... At present this feature is unavailable.

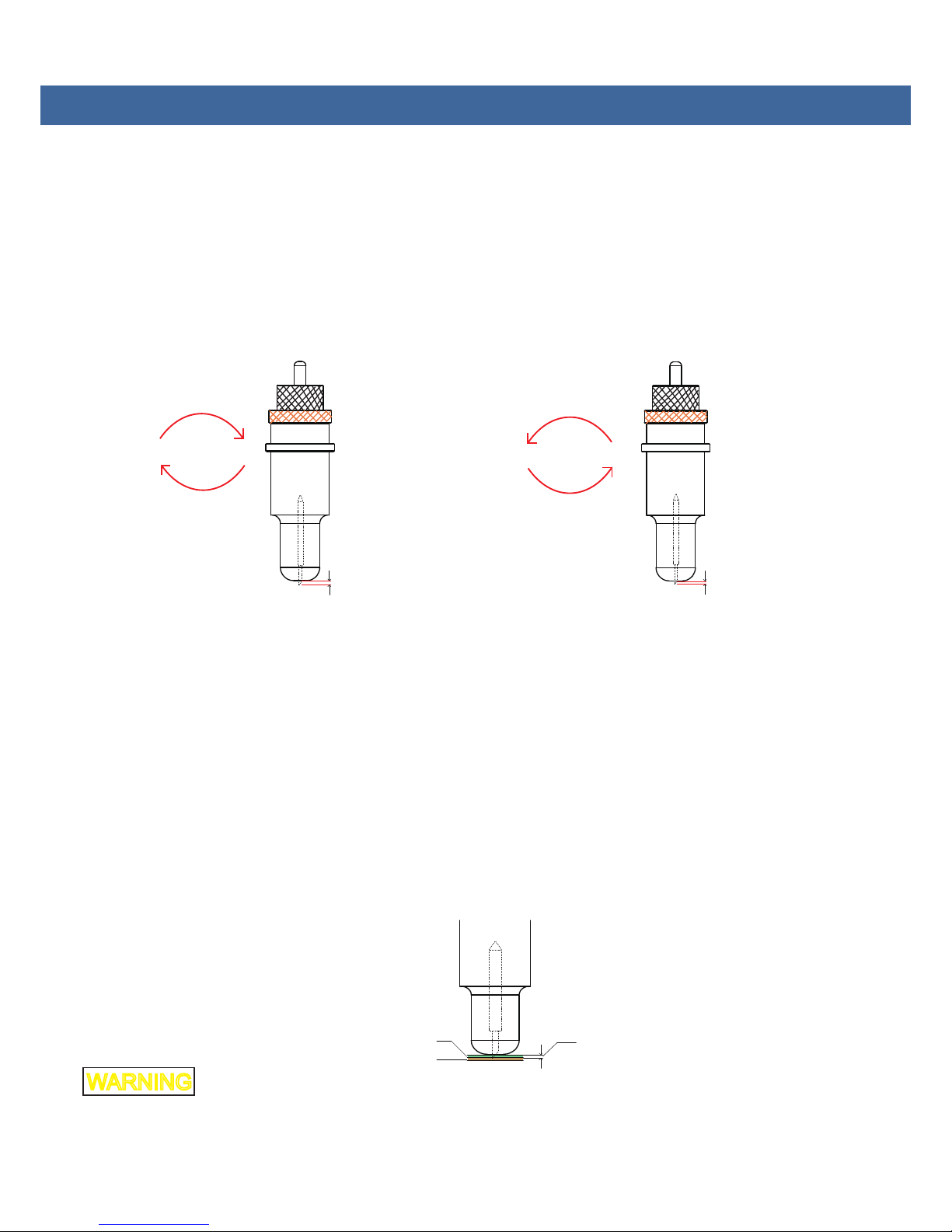

SPEED / FORCE:Control the speed and force of a tool holder 1, generally hold the pen and creasing tool.

SPEED1 / FORCE1:Control the speed and force of a tool holder 2, generally hold the blade.

CAR X/Y :Distance between tool holder 1 and tool holder 2, the offset value of the two tools.

generally do not need to change.

Work Mode:Cut Plotter --Control tool holder 1and tool holder 2 work together.

Draw Plotter--Control tool holder 2 work only.

BaudRate:38400,Computer and motherboard transmission parameters, generally do not need to change.

XP/YP:Scaling X direction and Y direction,generally do not need to change.

Clear Pare:Restore factory settings.

VER:The version for firmware.