GENERAL SAFETY TERMS

1. Machine’s Safety Accessories and Accident Prevention Terms

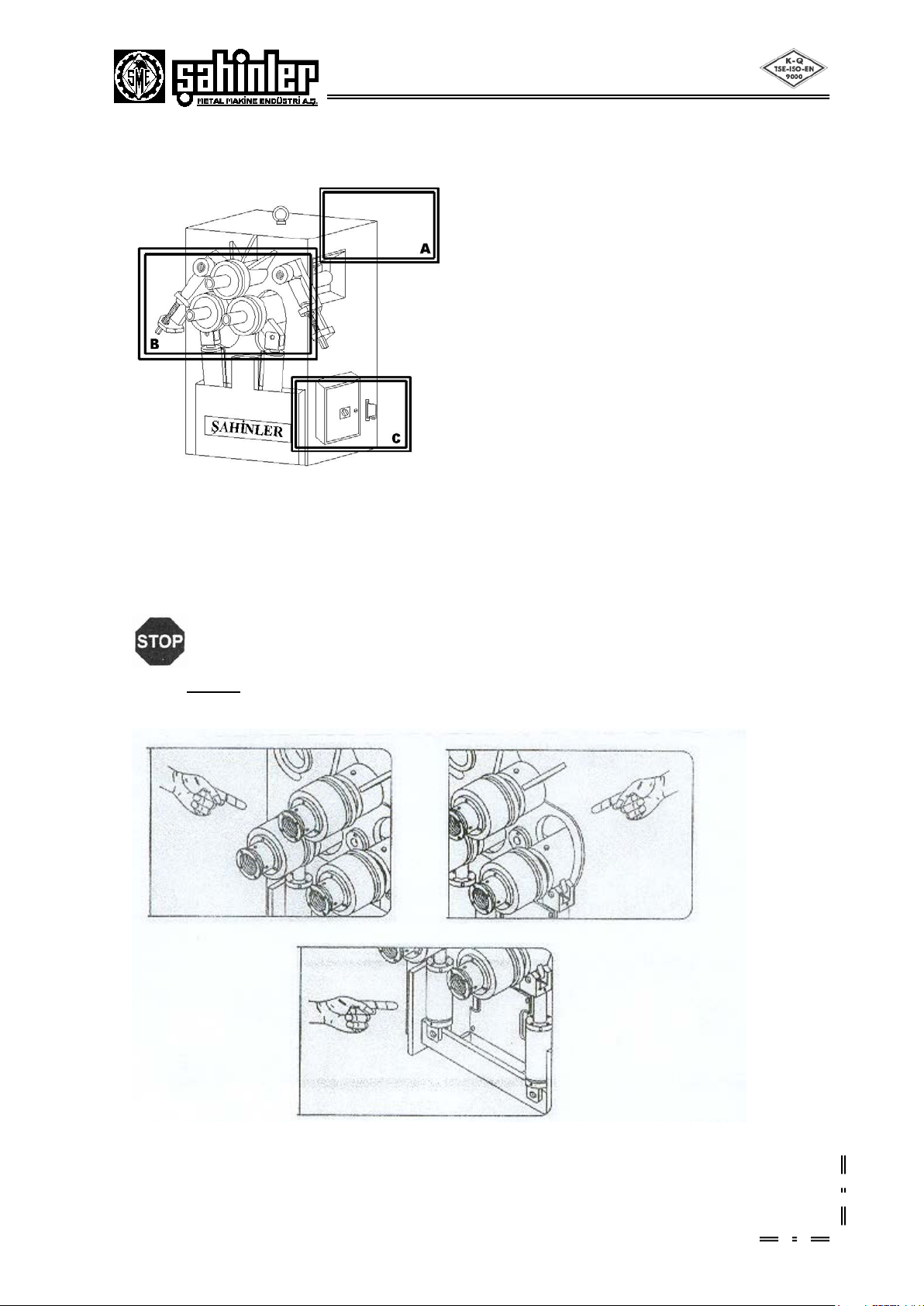

The machine is provided with fixed shelters for the protection of all gears. But some mobile

parts, because of their shape for the bending processing cannot be protected within a case.

However, safety is guaranteed by the machine features and by the use of “human presence”

controls.

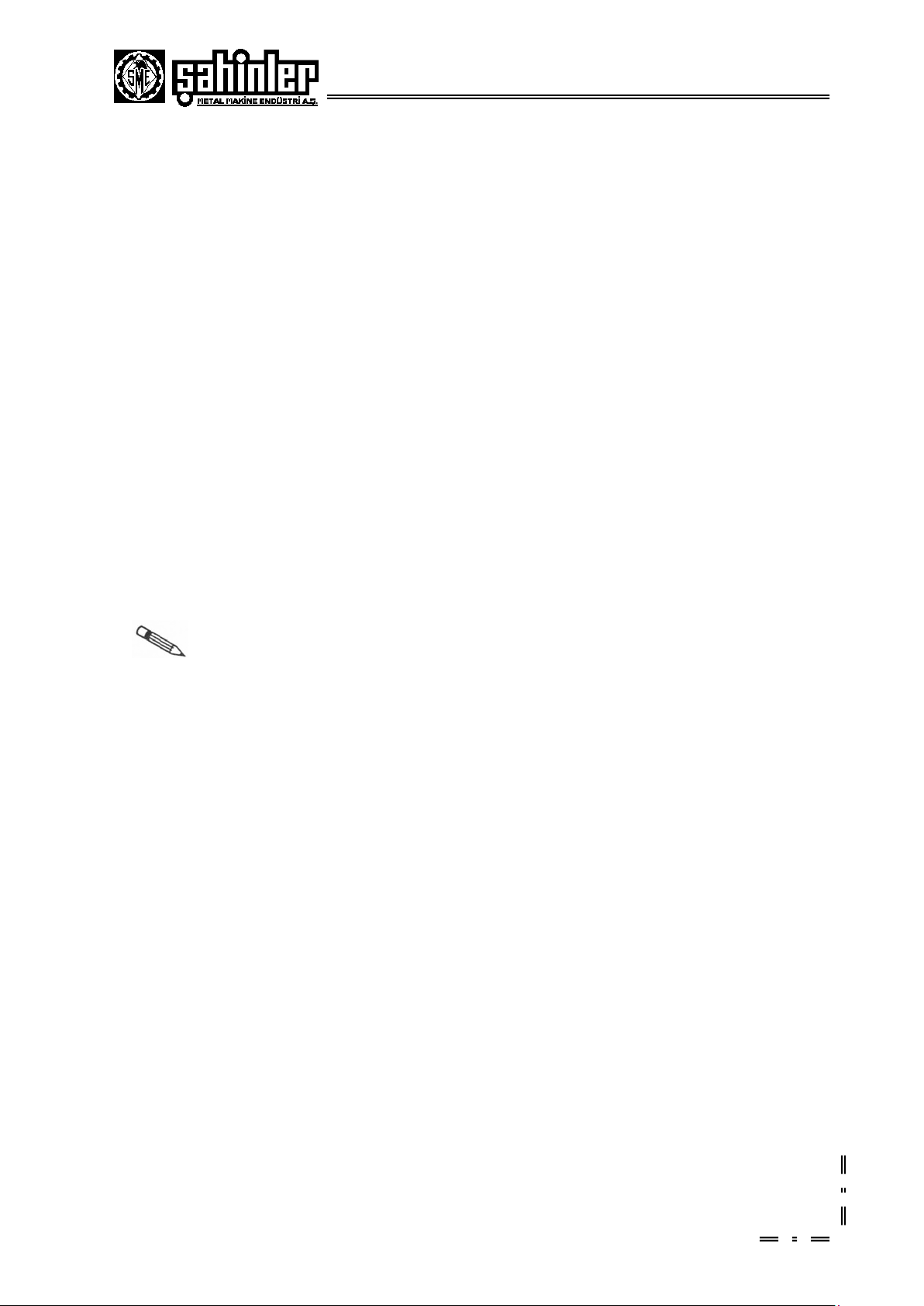

The machine is controlled by means of foot-pushed buttons present at the downside of the Mo-

bile Control Panel. During operation the specified safety distance must always be observed.

There is a red mushroom emergency button at the upside of the Mobile Control Panel to stop

all the machine activity by disabling the electric supply until released. In case of an extraordi-

nary situation, please push this button straight away.

No other persons except for the qualified and well-trained operator should be allowed to use

the machine and to be present in the working area of the machine.

Any damaged or defective connections to the different energy supplies must be replaced.

All interventions concerning installation, start-up, change of equipment, use, change to the use

and the operation, regular maintenance, inspection and periodical maintenance can be per-

formed only after disabling the machine according to relevant chapter of this handbook.

For any intervention to change the machine’s use, please contact to Şahinler Metal Mak. End.

A.Ş. previously and ask for their written approval.

2. Abnormal Conditions

In order to avoid unusual working conditions, in the following several recommendations to the

operator are listed. Also, do not forget that this machine can be used only in the conditions presented

in this operation and maintenance handbook.

Before connecting the machine double-check electrical connections read the instructions care-

fully. For, almost 65% of the failure reports we receive are based on either wrong electric con-

nection or use in contradiction to the User’s Manual.

Avoid the approach of persons to the operator while the machine is running.

Loading and unloading of the material should be done according to the instructions of this

handbook.

During the bending process avoid holding material with the hand.

Never wear garments with loose parts, which may be dragged by the machine parts, long loose

hair, necklaces, rings etc.

Never use goods except for the allowed ones as operational materials.

Never run the machine without safety devices.

Don’t climb on the machine.

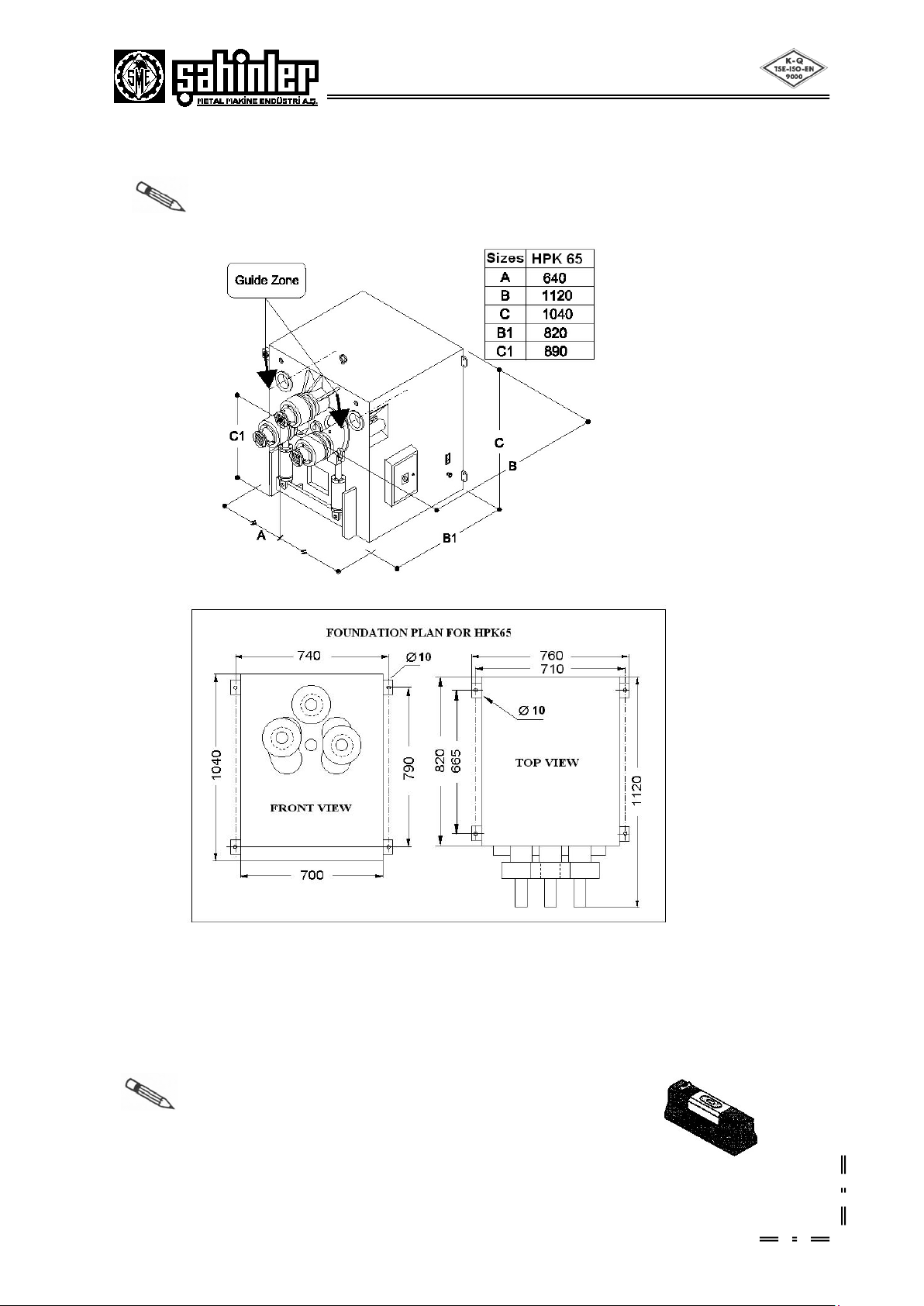

If the customer wants to install on the HPK 65 machine a piece of equipment, which has not

been supplied by Şahinler Metal Mak. End. A.Ş., the compliance with the safety conditions ex-

plained here has to be checked.

The machine cannot be installed and used in corrosive environments.

The machine must always be operated with one qualified operator who has the required knowl-

edge to use this machine properly.