www.sailwinlight.com

1:Short press the red button,when the display shows”FFF”,it means the machine has connected to

remote control,long press the red button,when the display shows“OFF”,it means the machine

has disconnected from the remote control.

2:”ON”button : turn on pre-heat,”OFF”button: turn off pre-heat

3:”1/2/3”button: working height, ”1”=F1; “2”=F2; ”3”=F3

4:”E-stop”button: emergency stop

5:”Clear Powder”button: Please press it to clear the remains in the pipe in case of remains being

stuck. Press “OFF” to stop this process.

6: Turning off: please press the red button for 3seconds.

Note:if you need to control machines in groups by remote control,you need to power on all the

machines in group A,all other machines are turned off,then press the red button on the A remote

control until the first group of machines displays “FFF”; the next, the machines in Group B are all

power on, press the red button on the B remote control until the B group machine displays “FFF”,

and so on. This is the A remote control group A, B remote control group B.

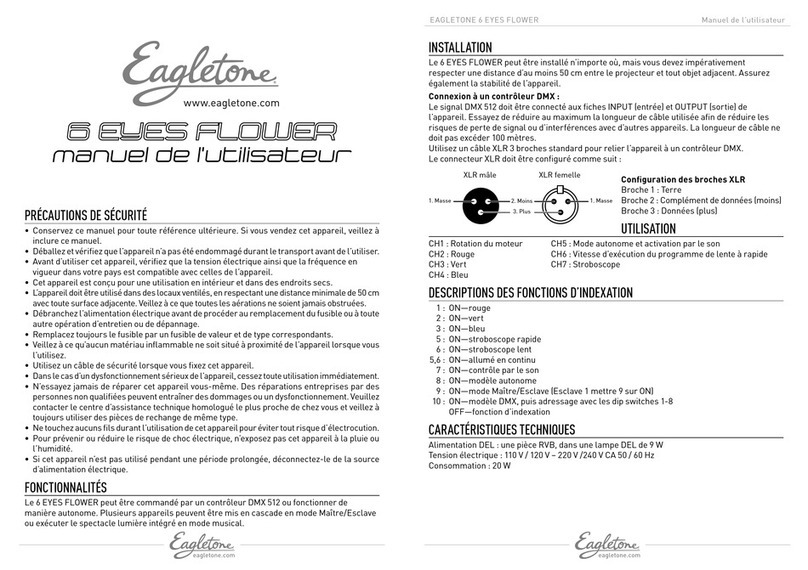

3:DMX512 signal control:

When using the DMX512 signal control mode, the signals between devices are connected in

parallel, so it is best to use twisted-pair shielded cables when connecting multiple devices. Each

device is connected via the DMX signal socket (cassette) INPUT and OUTPUT on the device. The

3-pin XLRXL connector terminals of the connected device must correspond to each other. When

connecting device signals, it is recommended to use the DMX signal terminator to avoid signal

reflection and damage signal control.

When the DMX console is successfully connected to the machine, the DMX signal light (blue) on

the machine flashes; the first channel (240-255) pre-heat function can be turned on, the HEAT

light (red) lights up, and the temperature Rise will be displayed on the machine screen; when the

heating is completed, the screen will display the DMX channel, and the READY lamp (green) will

change from blinking to steady state, indicating that the spray is ready, and the spray height can be

controlled through the second channel.