Please be careful when using your CNC machine. This machine is an electrical device with moving parts and

dangerous areas.

Genmitsu CNC Machines are for Indoor Use Only.

You must be 18 years or older to operate this machine, unless supervised by a knowledgeable adult familiar with the machine.

Wear the proper Personal Protection Equipment (Safety Glasses etc.).

Always place the CNC Machine on a stable surface.

The SainSmart Genmitsu CNC Machine is supplied with Switchable Power Supply 230VAC or 115VAC. Never use a different

power supply; it may cause malfunctions or damage to the machine.

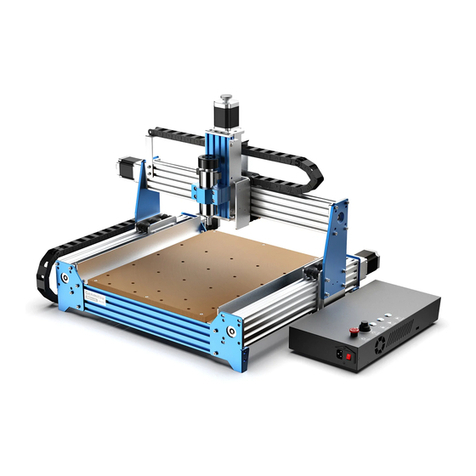

The 3020-PRO MAX utilizes a high amp power supply. It is recommended that you do not plug the CNC Router into an extension

cord, or power strip as it may damage the machine. (Need final confirmation)

Ensure the Emergency stop button is easily accessible at all times.

Never disassemble the Power Supply or Electrical Components. This will VOID the warranty.

DO NOT TOUCH the machine spindle, or place any body part near the working area when the machine is operating. Serious injury

may occur.

DO NOT leave children unsupervised with the CNC Machine even when it’s not operating. Injury may occur.

DO NOT leave the machine unattended while it's operating.

Ensure your CNC Machine is in a well-ventilated area. Some Materials may discharge smoke or fumes during operation.

●

●

●

●

●

●

●

●

●

●

●

●