Salda RWC Series User manual

Subject to technical modication

RWC-RFC _P0118_AZ_0001

DUCT WATER, FREON COOLERS

Technical manual

RWC

RFC

2

RWC/RFC

www.salda.lt

Cooling coils are used for air cooling in ventilation systems.

The coil consists of copper tubes and aluminium ns. The casing is made of galvanized sheet steel.

RWC-type coolers use coolant - cold water. RFC-type coolers use the R410A freon.

Easy to mount.

Suitable for operation indoor environment.

The purpose of the unit is: cooling of clean air. The unit is used in clean air ventilation and conditioning systems.

Units are packed in the factory to complay needs of normal transportation handling. Use suitable lifting and moving equipment when handling units in

order to prevent damages and injuries. Do not use cables, terminal boxes, and inlet-exhaust anges for lifting and moving units. Avoid hits and shock

loads. Units should be stored in dry rooms where relative humidity max. 70% (at +20oC), ambient temperature is within the range of +5oC to +40oC.

Units should be protected from dust, dirt and water.

Avoid long term storaging. Longer than 1 year is not recommended.

- Do not use the unit for purposes other than its’ intended use.

- Do not disassemble or modify the unit in any way. Doing so may lead to mechanical failure or injury.

- Use special clothing and be careful while performing maintenance, and repair jobs - edges of the components’ casings may be sharp and cutting.

- Do not place or operate unit on unsteady surfaces and mounting frames.

- Mount the unit rmly to ensure safe operating.

- Never use this unit in any explosive or aggressive elements containing environment.

- Installing should only be performed by qualied and trained sta.

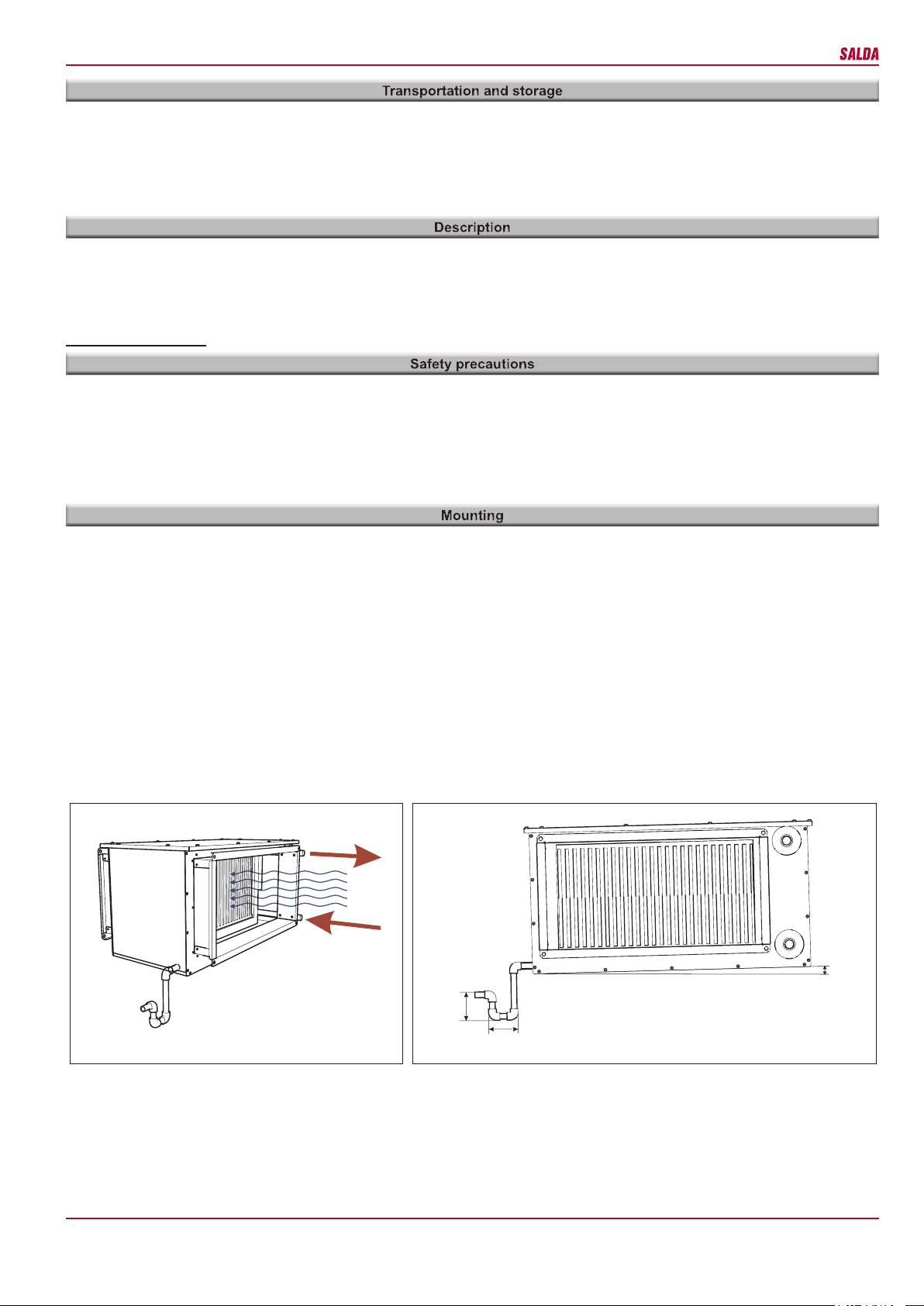

- Coils are designed for mounting in horizontal position.

- Water connection process should be processed using mounting scheme (see the scheme S1).

S1:

a - water ow out;

b - air ow;

c - water ow in.

When cooler is already mounted the draining system has to be connected. In order to do that siphon must be screwed to the cooler draining exhaust.

The draining system should be lled up with at least 0,5 l of water (siphon must be always lled with water).

Check if water reaches sewerage system.

Installed heaters must be 0-3o slope angle (g. S2).

a

b

c

~100 mm

~100 mm

0 - 3o

S2S1

3

RWC/RFC

www.salda.lt

Maintenance shall be performed only by experienced and trained qualied personnel.

During maintenance, it is recommended to check the proper operation of the product at regular intervals.

During the periodic inspection, make sure that:

1. There is no mechanical damage on the casing.

2. There is no coolant leak.

3. The system has proper pressure (it is especially important for RFC type freon coolers).

4. There is no air in the system of the RWC type water cooler.

5. There is proper uninterrupted water circulation in the system of the RWCtype water cooler.

6. The air ducts are connected tightly, i.e. there are no cracks, tears, or other mechanical damage that may cause leakage in the system.

Cleaning

If cooler is soiled it should be cleaned.

1. Detach unit from ventilation and water supply systems.

2. Coil can be cleaned using tepid water and alkaline micture which does not generate corrosion on aliuminium;

D [mm] C [mm] ød [mm] E [mm] B [mm] A [mm] K [mm] G [mm] L [mm] m [kg]

RWC 500x250 C4 500 250 1/2” 242 674 340 70 290 430 19,5

RWC 500x250 C2 500 250 1/2” 242 674 340 70 290 430 17,9

RWC 700x300 C4 700 300 3/4” 286 874 390 70 310 450 26,7

RWC 700x300 C2 700 300 1/2” 292 874 390 70 310 450 23,7

RWC 750x300 C4 750 300 3/4” 286 924 390 70 310 450 27,9

RWC 750x300 C2 750 300 1/2” 292 924 390 70 310 450 24,8

RWC 750x350 C4 750 350 3/4” 336 944 440 70 310 450 30,8

RWC 750x351 C2 750 350 1/2” 358 944 440 70 310 450 26,9

RFC 500x250 F4 500 250 16 240 674 340 70 290 430

RFC 500x250 F2 500 250 16 240 674 340 70 290 430

RFC 700x300 F4 700 300 16 290 874 390 70 310 450

RFC 700x300 F2 700 300 16 290 874 390 70 310 450

RFC 750x300 F4 750 300 28 278 924 390 70 310 450

RFC 750x300 F2 750 300 16 290 924 390 70 310 450

RFC 750x350 F4 750 350 28 328 944 440 70 310 450

RFC 750x350 F2 750 350 22 334 944 440 70 310 450

B

D

C

A

E

d

L

G G

K

31,5

19

DN 15(1/2'')

4

RWC/RFC

www.salda.lt

1. All equipment manufactured in our factory is checked in operating conditions and tested befor delivery. Test protocol is supplied together with the

unit. The equipment is shipped in good working order and condition to the direct client. The unit is warrantied for the period of two years from the

invoice date.

2. If equipment is found to have been damaged during transportation, a claim should be made against carrier, as we assume no responsibility for such

damage.

3. This warranty does not apply:

3.1. when transportation, storage, installation and maintenance instructions of the unit are violated;

3.2. when the equipment is improperly maintained, mounted - inadequate maintenance;

3.3. when the equipment without our knowledge and permission has been upgraded or unskilled repairs were made;

3.4. when the unit was used not for its original purpose.

4. This warranty does not apply at these malfunction cases:

4.1. mechanical damage;

4.2. damage caused by entering outside objects, materials, liquids;

4.3. damage caused by natural disaster, accident (voltage change in the electricity network, lightning, etc..).

5. The company assumes no liability for its products either directly or indirectly damage, if the damage is caused by failure to comply with installation

and mounting regulations, deliberate or careless users or third-party behavior.

These conditions are readily discernable when the equipment is returned to our factory for inspection.

If the direct client determines that equipment is found to be faulty, or a breakdown occurred, he should inform the manufacturer within ve working days

and deliver the equipment to manufacturer. Delivery costs should be covered by customer.

This manual suits for next models

17

Table of contents