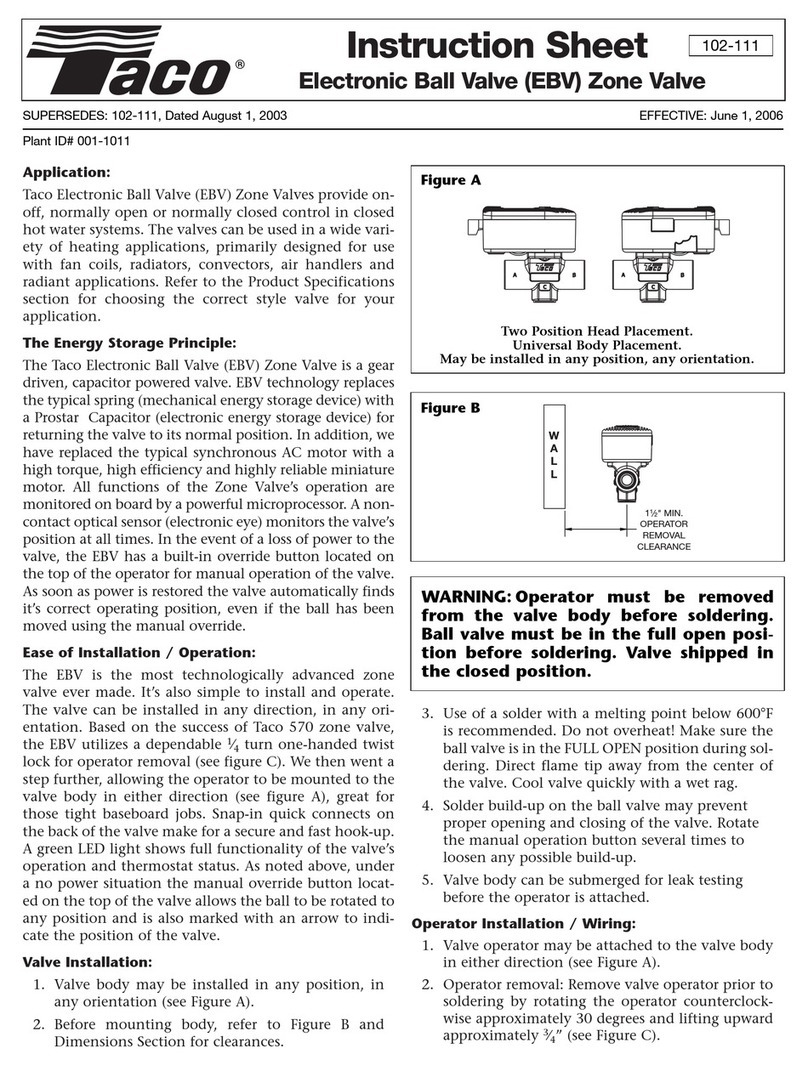

1. Valve body may be installed in any position, in any orientation (see Figure A). 3-way actuator’s power connections must be over the

supply port to ensure proper flow direction (see Figure A).

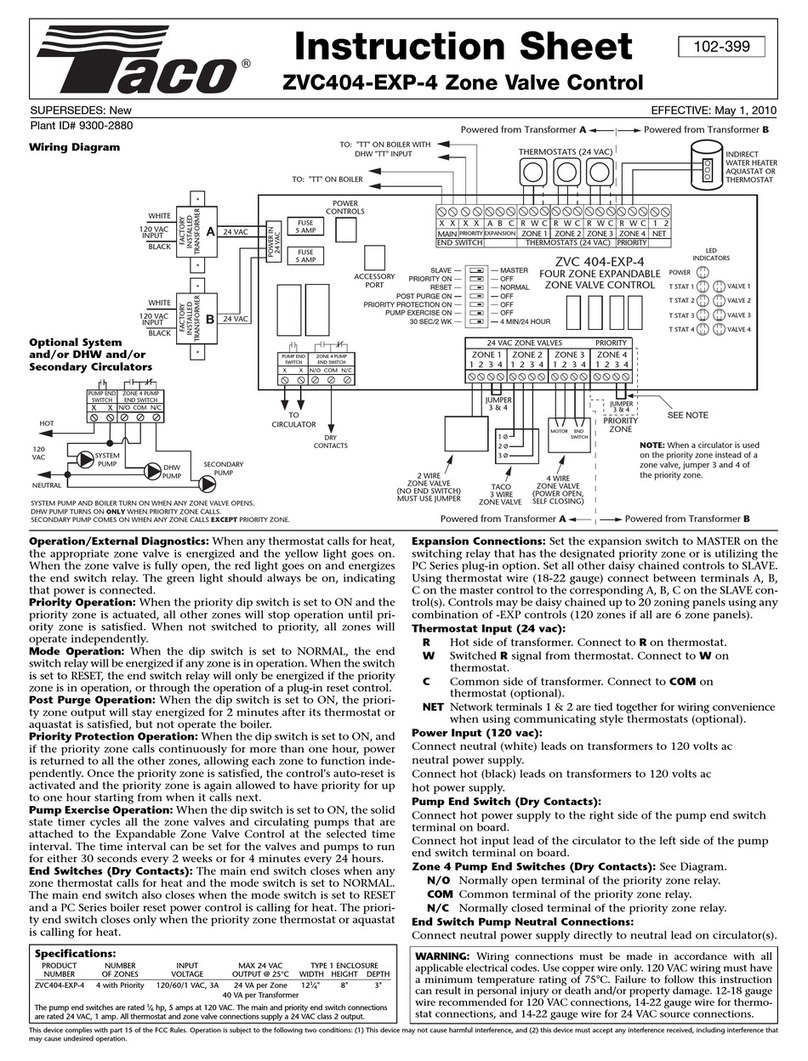

2. Before mounting body, refer to Figure B and Dimensions Section for clearances.

3. Use of a lead or tin based solder with a melting point below 600°F is recommended. Do not overheat. Make sure the ball valve is in

the FULL OPEN position during soldering. Direct flame tip away from the center of the valve. Cool valve quickly with a wet rag.

4. Solder build-up on the ball valve may prevent proper opening and closing of the valve. Rotate the manual operation button several

times to loosen any possible build-up.

5. Valve body can be submerged for leak testing before the actuator is attached.

Actuator Installation / Removal

1. Valve actuator may be attached to the valve body in either direction (see Figure A). The 3-way actuator must be attached with the

power connections over the supply port to ensure proper flow direction (see Figure A).

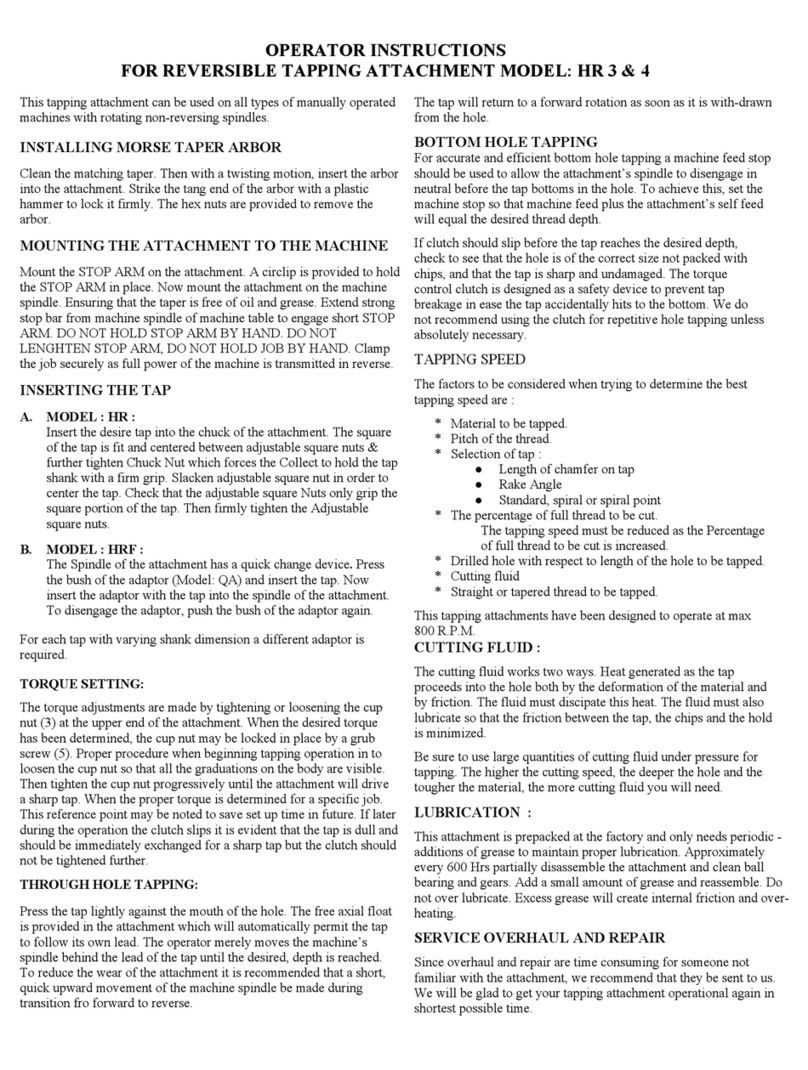

2. Actuator removal: Remove valve actuator prior

to soldering by rotating the actuator counterclock-

wise approximately 30 degrees and lifting upward

approximately 3/4” (see Figure C).

3. To re-assemble actuator to valve body: Position

actuator such that the “D” shaped valve stem aligns

properly with the “D” shaped actuator drive cavity

(Note: The “D” shaped stem design allows for cor-

rect insertion every time). Next, slide valve stem

into actuator cavity and rotate until the actuator

slips over the valve’s locking posts (see Figure C),

once the actuator is flush with valve body, turn actu-

ator clockwise and lock into position.

Wiring and Sensor Installation

All terminals provided with the iSeries-R are removable. In order to prevent

damage to the electronics, disconnect all plugs before the power is turned on

and check voltages and sensors. Once the circuits are tested, plug in the ter-

minals.

Powering the Control

For intermittent operation, connect one side of the end switch (e.g. Taco

ZVC/SR series zone control) or thermostat to an external 24 V (ac) trans-

former. Connect the other side of the zone control’s end switch to the R ter-

minal on the iSeries-R. The C terminal must then be connected to the other

side of the transformer. For continuous operation, simply wire the transformer

directly to the R and C terminals on the iSeries-R. Ensure that no power is

present during this process.

Sensors

Do not apply power to these terminals as this will damage the iSeries-R. The

wiring terminals for the sensors may be removed for ease of installation.

Outdoor Sensor

Remove the screw and pull the front cover off the sensor enclosure.

The outdoor sensor can either be mounted directly onto a wall or in a 2” x

4” electrical box. When the sensor is wall mounted, the wiring should enter

through the back or bottom of the enclosure. Do not mount the sensor with

the conduit knockout facing upwards as rain could enter the enclosure and

damage the sensor.

WARNING: Wiring connections must be made in accordance with all applicable electrical codes.

CAUTION: To prevent electrical shock, disconnect electric power to system at main fuse or

circuit breaker box until installation is complete. When a service switch is installed, more than

one disconnect switch may be required to deenergize this device for servicing.

Figure C: Actuator Removal

Step 1

Rotate actuator counter

clockwise approximately 30

degrees

Step 2

Move actuator upward

3/4" to discharge

Locking

Post

4