6

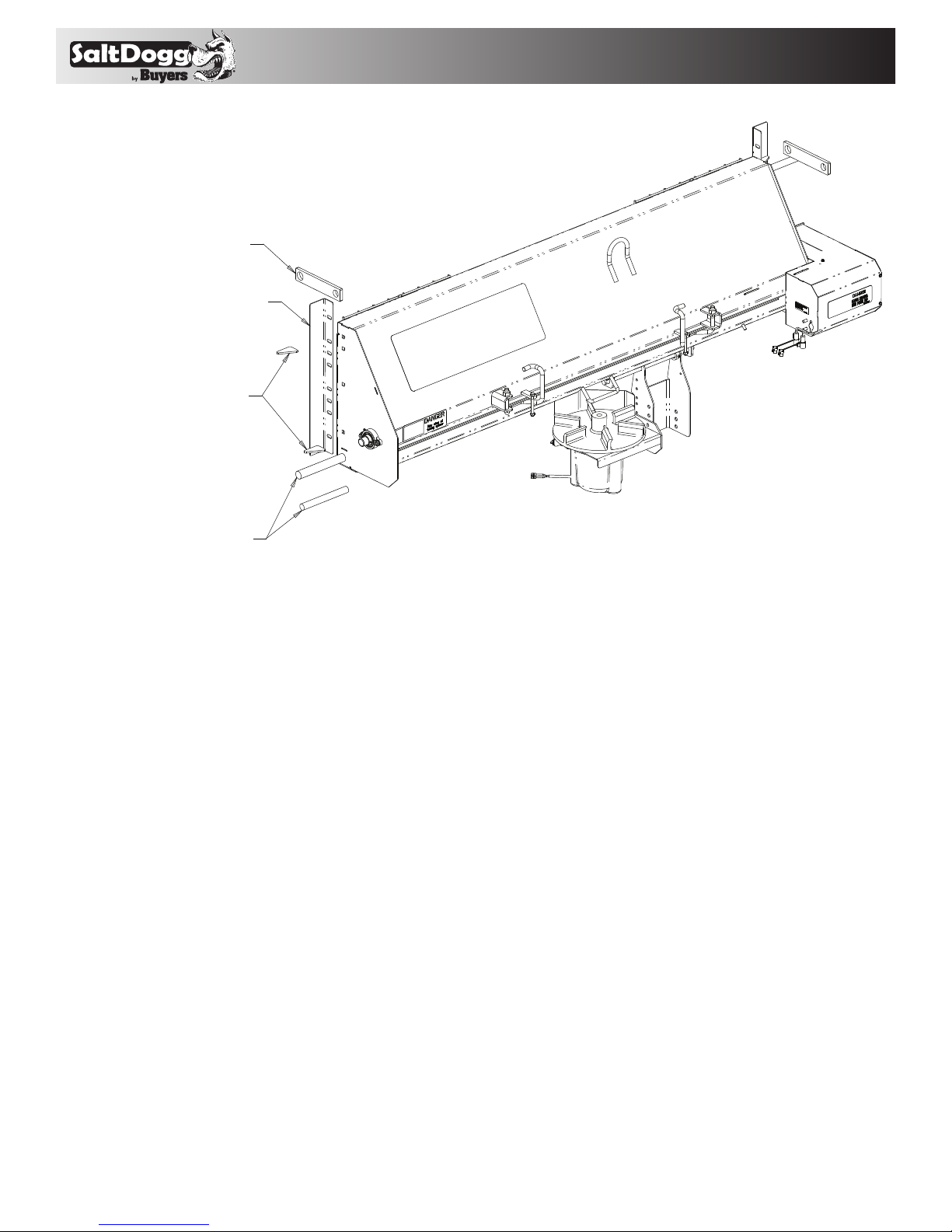

3. Using the Auger Lock-out System

A. Shut off spinner and auger and position the main

hydraulics on/off lever to off.

B. Remove the lock-out pin, rotate the handle, and

insert the pin through the holes in the handle and

the bracket to prevent accidental engagement of the

hydraulics. (see illustration below)

C. The lower tray may now be opened for servicing

the auger.

D. After servicing, first close and lock the tray then

reverse the steps to move the handle and pin back to

their original positions. BE SURE TO REINSERT THE

LOCK-OUT PIN THROUGH THE HOLES IN THE

HANDLE AND THE BRACKET.

E. Turn the main hydraulics back on and the spreader

is ready for operation.

DANGER

Before working in or around the auger area, the valve

control lever must be in the off position. Disengage PTO,

shut off engine, and follow the auger lock-out instructions.

MAKE SURE THE LOCK-OUT PIN IS ALWAYS USED IN BOTH

THE ON AND OFF POSITIONS. After servicing is complete,

reverse the process to restore the spreader function.

NEVER PUT ANY PART OF YOUR BODY INSIDE THE AUGER

AREA OF SPREADER.

Auger ON

Auger OFF

4. Miscellaneous

A. Valve setting changes may be made with truck in

motion.

B. By moving on/off lever to the off position, spinner

and auger may be stopped at the same time without

changing their valve settings.

C. Close cover plate flat over spreader trough and

lock in place for normal use of dump truck. Tailgate

may be opened from top or bottom.

D. When truck is used for extensive hauling the

spinner assembly should be removed.

E. If auger clogs, shut off spinner, open auger knob

valve and increase the engine speed. With the engine

at a higher speed, move the valve lever from the on to

the off positions rapidly; repeat as needed. This action

may unclog the auger. If this action fails to free the

auger, manual unclogging will be required.

CAUTION

Position the valve on/off control lever in the off position

when the spreader is not in use or is removed. In the

event the valve on/off control lever is left in the on posi-

tion, a heat problem may occur as the pump continues to

pump oil to the hydraulic valve. This could cause a hose

to burst spraying hot oil.

Recommended Maintenance

A. Warm up hydraulic system before using.

B. Keep the reservoir 3/4 full with high grade

nonfoaming hydraulic oil.

C. Use precautions to keep contaminants from getting

in reservoir when filling.

D. Quick connects are a prime source of contamination.

1. Clean quick connects before connecting or

disconnecting them.

2. Protect quick connects from contaminates.

E. Lubricate all bearings with suitable type grease

on a regular basis. More frequent lubrication is

recommended during periods of heavy use.

F. Lubricate the spinner hinge rod periodically.

G. Maintain the proper lubrication level in all

gearboxes with SAE 90 gear lubricant.

H. When not in use, keep the spreader tray empty to

prevent freezing of material around auger in extremely

cold weather.

I. To extend the life of your spreader:

1. Hose down and clean after each use.

2. Repaint and/or oil after each season.