2

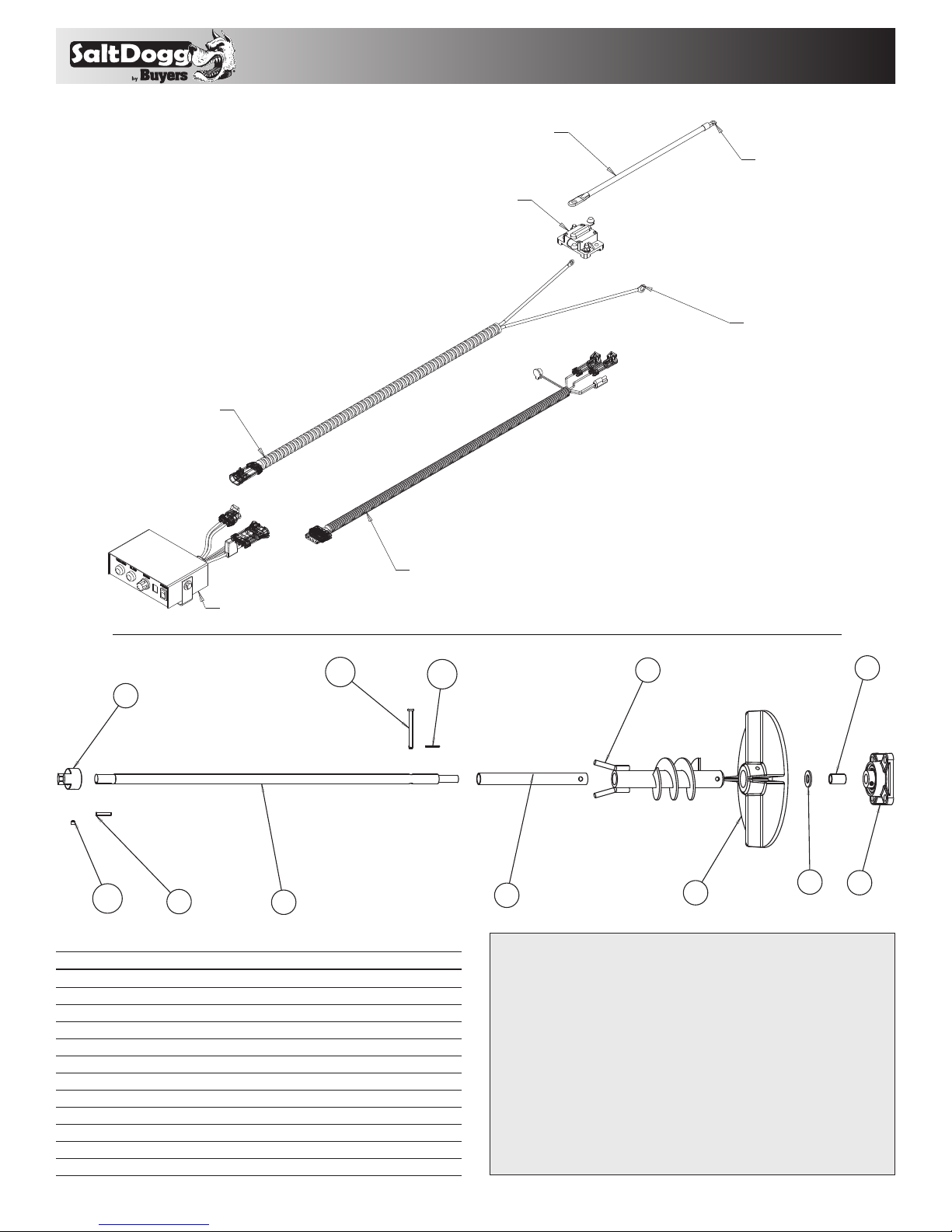

ELECTRICAL INSTALLATION

WARNING!

Do not drill holes into fuel tanks, fuel lines,

through electrical wiring, etc that may be

damaged by drilling.

To insure good performance of your spreader, check

the condition of truck’s electrical system. Using digital

voltmeter, check alternator and battery voltage. With

engine running and head lights and heater fan ON

good voltage reading should fall between 13.0 and

15.3 volts. If voltage reading falls out of this range,

check and adjust your electric system.

NOTE: Always disconnect battery before attempt-

ing to install electrical components on your

vehicle.

• Mount the controller in a convenient location in the

truck cab. It is recommended not to mount the con-

troller directly in front of heat vents.

• Route both wire harnesses into truck cab through

firewall (it maybe necessary to drill holes). Insulate

hole to avoid water leaks.

• Insure no wires are nicked or damaged during

installation.

• Connect the 4-pin connecter on the wire harness to

the control box.

• Connect the 2-pin connector on the power cable to

the control box.

• Lay out a path for the power cable to the bat-

tery, use quick ties to secure power cable. DO NOT

CONNECT TO BATTERY AT THIS TIME!

• Lay out path for wire harness to the rear of the vehi-

cle. It is recommended to stay clear of the exhaust

system. Excess heat can damage the wire harnesses.

Use quick ties to secure harness to underbody.

• Connect the wire harness to the motor.

• Connect the power and ground cables directly to

the battery.

• Insure all functions of the controller are working

properly.

Observe spinner direction of rotation. The correct

direction is counter clock wise when looking

inside hopper from the top. If direction is clock

wise reverse wires between Motor and Wire

Harness.

IMPORTANT!

Make sure all wires are securely attached to

vehicle or spreader’s frame. Use wire ties and/

or wire clamps to attach wires. All excess wires

must be rolled into bundles and attached to

vehicle or spreader.

SPREADER MAINTENANCE

1. This spreader is designed to use lose free floating

materials such as #1 dry Rock Salt. Using different

grades and/or wet material will affect spreader per-

formance. Wet material can “bridge” and stop floating

onto spinner disk.

2. Make sure lid is installed and latches are secured

when spreader is in use.

3. Do not leave material in hopper between uses.

4. Do not drive with material in hopper.

5. Always clean/ wash hopper and lubricate bearing

at the end of the day.

6. Spray lubricant around motor shaft to prevent

water from penetrating into the motor.

7. Apply dielectric grease to all electrical connectors

between uses and for long term storage.

CAUTION!

DO NOT ATTEMPT TO INSTALL OR REMOVE

SPREADER WITH MATERIAL IN IT.