7. CONSIDERATIONS

1. In order to weaken the influence of the measured material on the accu-

racy of measurement, it is recommended that the calibrations should be

done on the uncoated material to be measured.

2. Probes will eventually wear. Probe life will depend on the number of

measurements taken and how abrasive the coating is. Replacement of a

probe can be fitted by qualified persons only.

8. RESTORE FACTURY SETTINGS

1. When to restore?

It is recommended to restore factory settings in the one of following cases.

A. The gauge does not measure any more.

B. Measurement accuracy is degraded caused by the abraded probe or by

environmental conditions changed greatly.

2. How to restore?

Restore factory settings includes `Fe` setting and `NFe` setting. You can restore

one of them or both of them respectively. Please follow procedures below to

restore factory settings.

1. Please note the symbol on the display is `Fe` or `NFe`. If `Fe` is on the display,

the operation below is restoring the factory setting for `Fe` type. And if `NFe`

on the display, the operation below is restoring the factory setting for `NFe` type.

2. Depress Power key and not release it till `CAL` appears on the display. It is

about 6 seconds from starting depressing Power key.

3. When F:H or nF:H is on display, lift the probe to more than 5 centimetres.

Then press the Zero key again and the gauge returns to measurement state.

The factory setting is restored.

9. HOW TO IMPROVE THE ACCURACY OF FULL RANGE BY LN

1. It is strongly recommended that no changes should be made to the value of Ln

which will seriously affect the accuracy. Its value can be adjusted by professional

person only.

2. To call the Ln, just depressing the Power key and not release it until Ln shows on

the display. It takes about 13 seconds from starting depressing Power key. After

Releasing the Power key, the Ln value shows on the display.

3. The Ln value can be changed by Up/Down key in Fig. 2. Generally, the larger the

Value of Ln, the smaller the reading on a same thickness. A little variation of value

of Ln will cause a great change in reading at high end (e.g. at 500 µm/20mil).

The rules to adjust the value of Ln are as follow:

A. Reading at low end can be adjusted to the exact value by the Up or Down key.

B. To enlarge the Ln, if readings at low end (e.g. at 51 µm) is ok but reading at high

end (e.g. at 432 µm) is too large. On the contrary, to decrease the Ln, if reading at

low end (e.g. at 51 µm) is ok but reading at high end (e.g. at 432 µm) is too small.

C. Repeat procedures from A to B till the readings on every standard foil are

satisfying the accuracy.

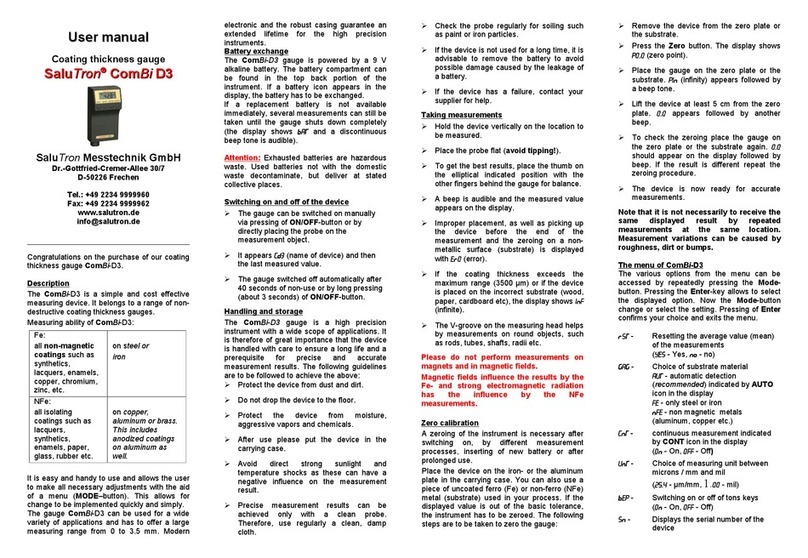

Operation Manual

SaluTronComBi D1000

This Coating Thickness Gauge is small in size, light in weight, easy to

carry. Although complex and advanced, it is convenient to use and

operate. Its ruggedness will allow many years of use if proper operating

techniques are followed.

Please read the following instructions carefully and always keep this manual w

ithin easy reach.

1. FEATURES

•It meets the standards of both ISO 2178 and ISO 2360 as well as

DIN, ASTM and BS. Suitable for the laboratory and for use in

harsh field conditions.

•The Fe probes measure the thickness of nonmagnetic materials

(e.g. paint, plastic, porcelain enamel, copper, zinc, aluminium, chrome

etc.) on magnetic materials ( e.g. iron, nickel etc.). Often used to

measure the thickness of galvanizing layer, phosphate layer, copper

tile, aluminium tile, some alloy tile, paper etc.

•The NFe probes measure the thickness of nonmagnetic coatings on

non-magnetic metals. It is used on anodizing, varnish, paint, enamel,

plastic coatings, powder etc. applied to aluminium, brass, non-

magnetic stainless steel etc.

•Automatic substrate recognition

•Manual or automatic shut down

•Two measurement mode:

Single and Continuous

•Wide measuring range and high resolution

•Metric/imperial conversion

•Digital display gives exact reading with no guessing or errors

2. SPECIFICATIONS

Display: 4 digits, 10 mm LCD

Range: 0 ∼1250 µm / 0 ∼50 mil

other ranges may be specified

Resolution: 0.1 µm (0 ∼99.9 µm)

1 µm (over 100 µm)

Accuracy:

Power supply:

Operating condition:

Size:

Weight:

±<6% or 3.0 µm or 0.12mil

(Whichever is the larger)

4 x 1.5 AAA(UM-4) battery

Temp. 0°C ∼50°C, Humidity <80%

126 x 65 x 27 mm (5.0x2.6x1.1 inch)

about 81 g (not including battery)