1

CONTENTS

1. FOREWORDS ..........................................................................................................................................2

1.1. HISTORY...................................................................................................................................................... 2

1.2. LEEB HARDNESS TEST (DEFINITION) .................................................................................................................. 2

1.3. NOTATION OF LEEB’S HARDNESS ...................................................................................................................... 2

2. FEATURES AND APPLICATIONS................................................................................................................3

2.1. INTRODUCTION............................................................................................................................................. 3

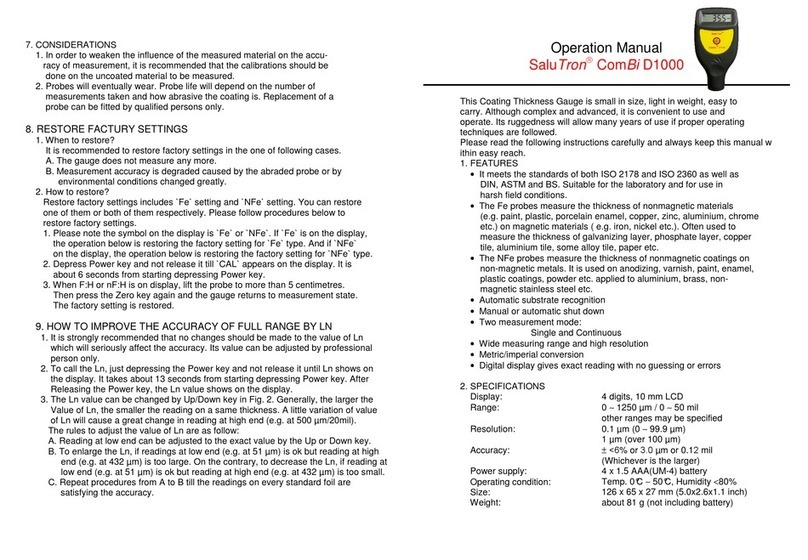

2.2. SPECIFICATIONS ............................................................................................................................................ 3

2.3. KEY FEATURES .............................................................................................................................................. 4

2.4. APPLICATIONS .............................................................................................................................................. 4

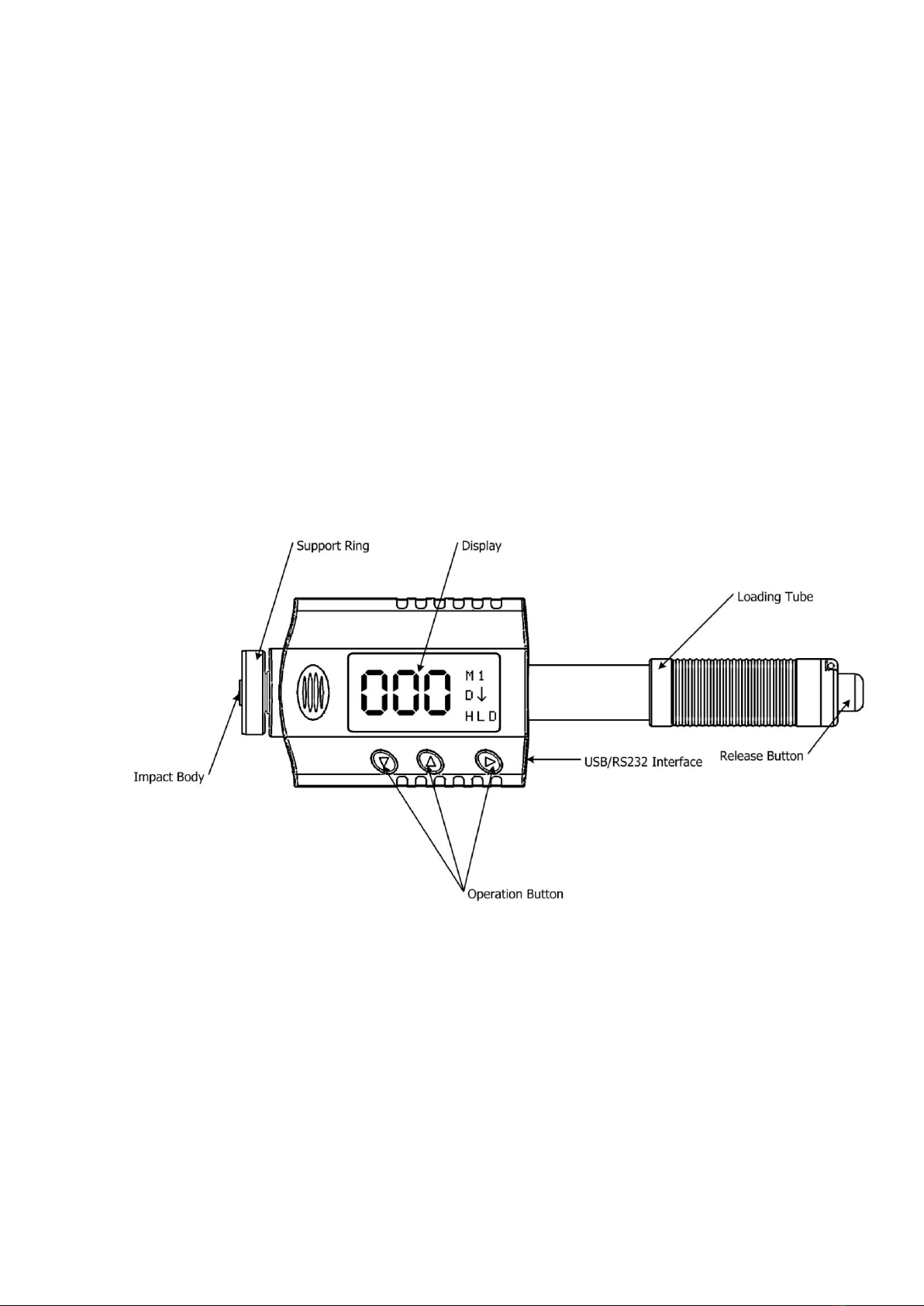

3. LAYOUT OF INSTRUMENT .......................................................................................................................4

4. SYMBOLS AND ILLUSTRATIONS...............................................................................................................5

4.1. SYMBOLS AND ILLUSTRATIONS ......................................................................................................................... 5

4.2. MEASUREMENT AND CONVERSION TABLE .......................................................................................................... 5

5. PREPARATION BEFORE MEASURING .......................................................................................................6

5.1. REQUIREMENTS FOR THE SAMPLE ..................................................................................................................... 6

5.2. REQUIREMENTS FOR THE WEIGHT OF THE SAMPLE................................................................................................ 6

5.3. REQUIREMENT FOR THE SURFACE HARDENED LAYER OF THE SAMPLE ........................................................................ 6

5.4. SURFACE OF THE TEST SAMPLE SHOULD NOT BE MAGNETIC. ................................................................................... 7

5.5. FOR TEST SAMPLE OF CURVING SURFACE ............................................................................................................ 7

5.6. SUPPORTING THE SAMPLES DURING TESTING...................................................................................................... 7

5.7. SAMPLES WITH CURVED SURFACES ................................................................................................................... 7

6. OPERATION ............................................................................................................................................8

6.1. BUTTON DESCRIPTION.................................................................................................................................... 8

6.2. DIAGRAM OF OPERATION ............................................................................................................................... 9

6.3. POWER ON THE INSTRUMENT ........................................................................................................................ 10

6.4. PARAMETERS SETUP..................................................................................................................................... 10

6.5. STATISTICS SETUP ........................................................................................................................................ 13

6.6. MEMORY SETUP ......................................................................................................................................... 14

6.7. DATA TRANSFER.......................................................................................................................................... 17

6.8. FUNCTION SETUP ........................................................................................................................................ 18

7. CHANGING IMPACT BODY ....................................................................................................................22

8. TAKE MEASURING.................................................................................................................................22

8.1. LOADING SPRING ........................................................................................................................................ 22

8.2. TAKE MEASUREMENT ................................................................................................................................... 23

8.3. RELEASE THE TESTING FORCE ......................................................................................................................... 23

9. MAINTENANCE AND REPAIR.................................................................................................................24

9.1. MAINTENANCE OF THE IMPACT DEVICE ........................................................................................................... 24

9.2. CHARGING BATTERY .................................................................................................................................... 24

9.3. SYSTEM RESET ............................................................................................................................................ 25

10. OPTIONAL ACCESSORIES ..................................................................................................................26

10.1. SUPPORT RINGS AND IMPACT BODY ................................................................................................................ 26

10.2. MICRO PRINTER.......................................................................................................................................... 26

11. PC SOFTWARE ..................................................................................................................................28

11.1. INSTALLATION OF HARDWARE DRIVER .............................................................................................................. 28

11.2. INSTALLATION OF SOFTWARE ......................................................................................................................... 28

11.3. OPERATION OF PC SOFTWARE ....................................................................................................................... 29

11.4. QUIT THE PROGRAM .................................................................................................................................... 36