P4

BASIC SAFETY

Many agricultural machines have potentially dangerous moving parts, which can cause serious or fatal

injuries. Remember;

1. Read ALL warning labels on the machine and ensure you understand operating instructions

2. Turn o the tractor before removing any guards, blockages or servicing the machine

3. Never use your hands or fingers to check for hydraulic oil leaks

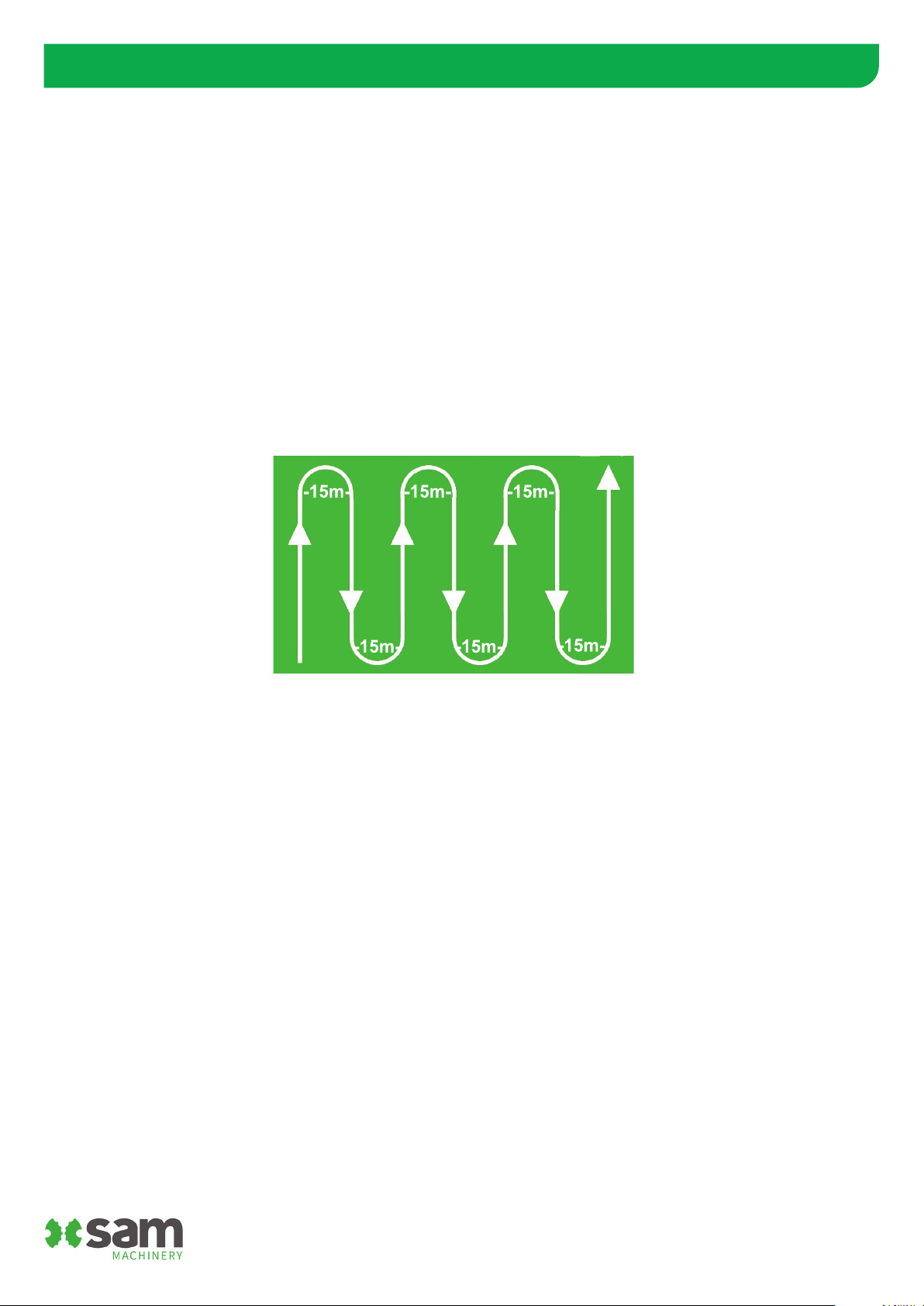

4. Keep at least 15 metres distance from the spinner discs when operating

5. Do not use the machine in steep areas where there is a high-risk of roll-over occurring.

OPERATIONAL CHECK

Before you start work with a machine there are a few basic checks that can be carried out. Ask yourself:

1. Is the machine you intend to use suitable for the job e.g. in good working order and safe to use?

2. Are all safety devices such as guards in place and working correctly?

3. Are there any known mechanical defects – pay particular attention to items such as wheels and tyres, and

moving parts?

4. Are you (or the operator) properly trained to do this job/use this machine?

5. Has the instruction manual for the machine been provided, read and understood?

6. Is the right personal protective equipment (PPE) available and being worn?

7. Has a risk assessment been carried out?

8. Has the work been properly planned and communicated to those who may be at risk?

9. Is the machine operator competent to do the job safely?

10. Hitching and attachment points for trailed machinery - check that it has been safely attached to the

towing vehicle such as a tractor. Pay attention to the condition of drawbar/pick-up hitch, and hitch rings,

pins, clips etc.

11. Carry out any pre-use checks as specified.

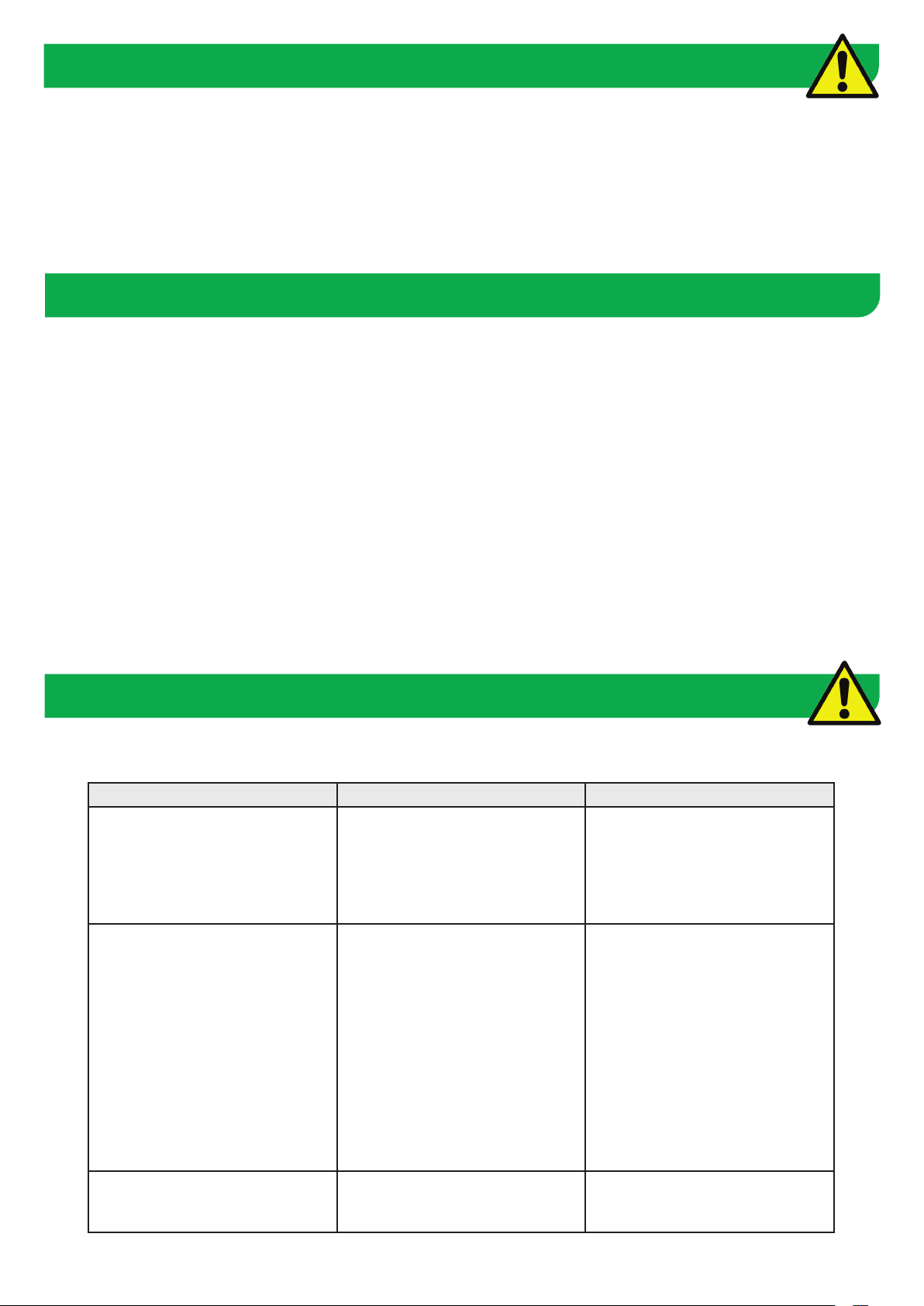

HEALTH & SAFETY RISK ASSESSMENT

A hazard identification, assessment and control procedure has been conducted on a representative

SAM Spreader and where necessary appropriate risk control measures have been outlined below;

HAZARD HARM CONTROLS

Contact, impact or entanglement

from moving parts/ loose objects

inc. gears, chains, sprockets, spinner

shas and discs, and wheels.

1. Deep cuts or amputation

2. Bruising

3. Fractures

Avoid wearing loose clothing,

jewellery or gloves - they increase

the risk of entanglement.

Stand a safe distance from the

machine when under operation.

Leaking hydraulic hoses and/or

couplings.

1. Leaking oil may get into skin

2. Skin and eye irritation

3. Breathing diiculties

Apply a programme of preventive

maintenance (hydraulic hoses and

hydraulic hose couplings).

Leaking oil, or bulging or abraded

hose walls, must have faulty parts

replaced.

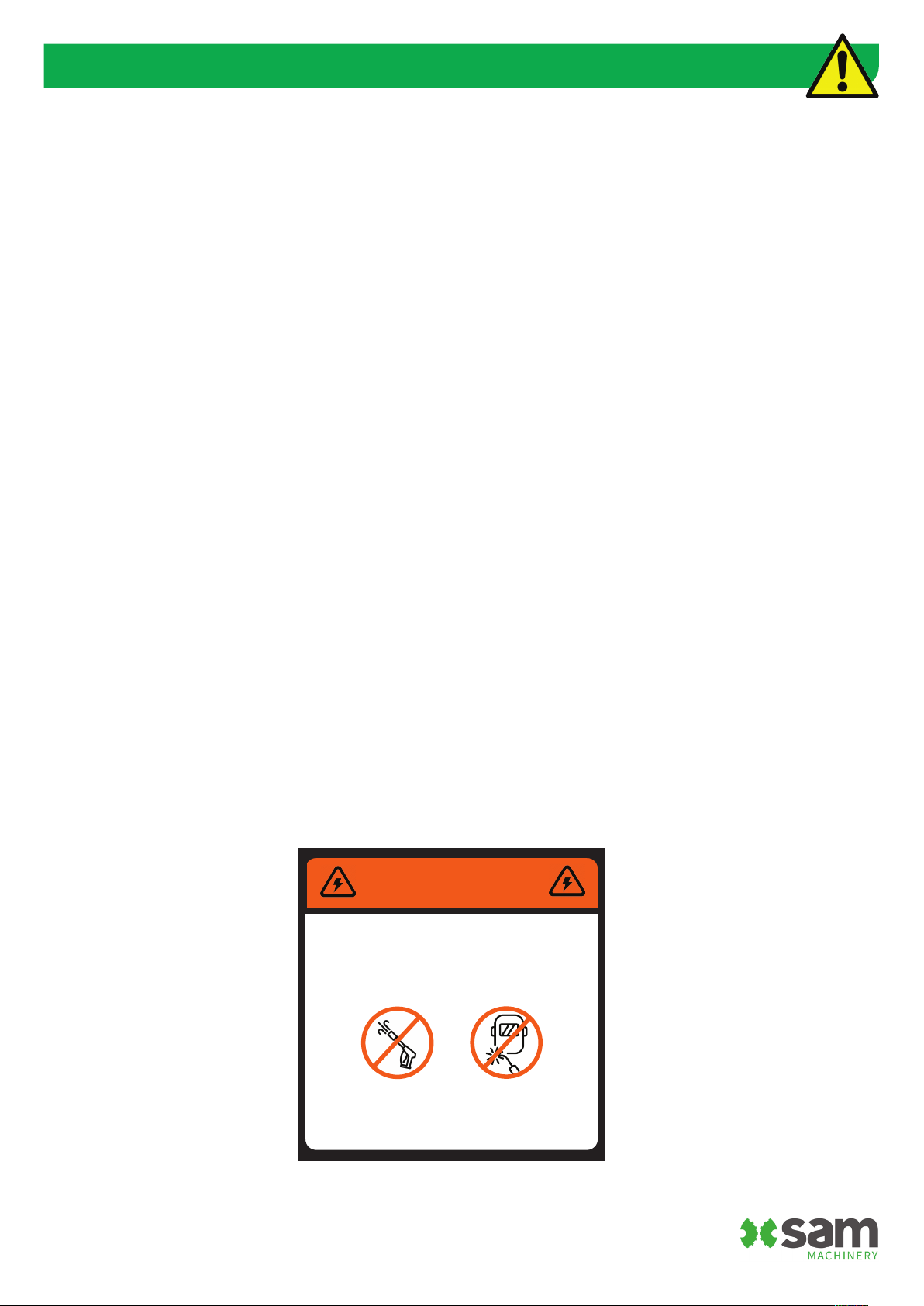

Never use hands or fingers to

detect leaks.

Wear appropriate PPE

(personal protective equipment).

Tractor and/or Fertiliser Spreader

roll-over due to instability under

varying conditions and terrain.

1. Serious injury

2. Fatality

Do not use the machine in steep

areas, or on unstable ground.