Index revision : 3

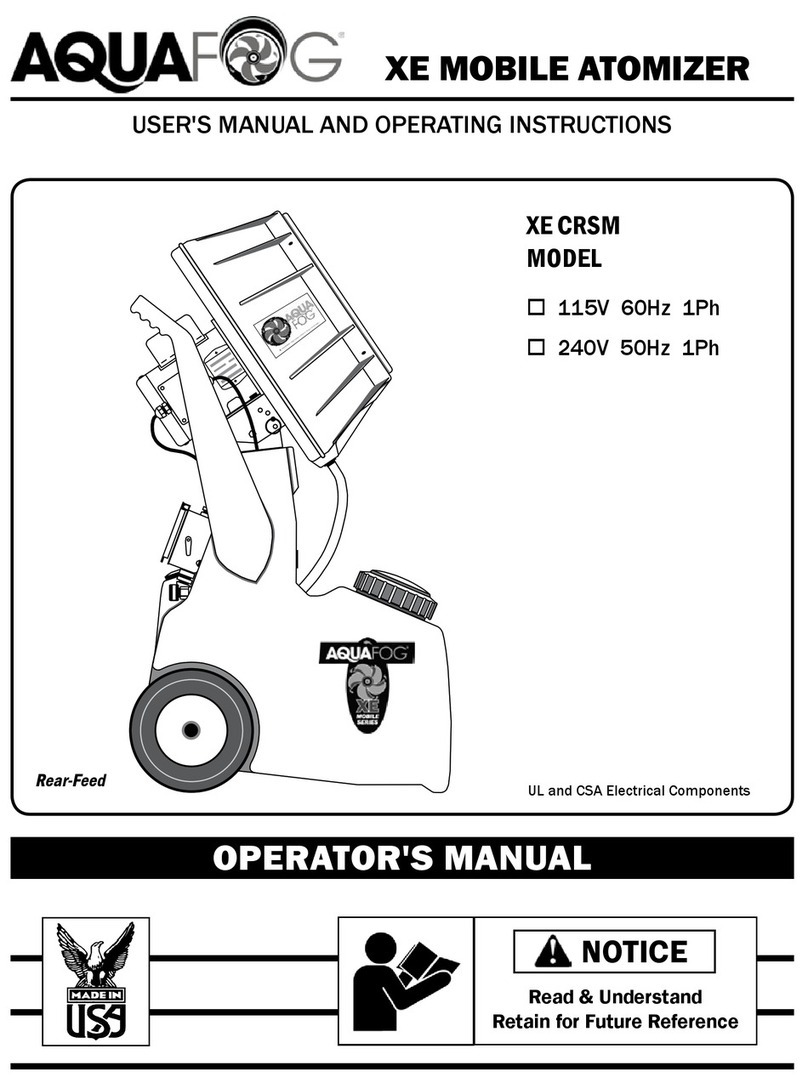

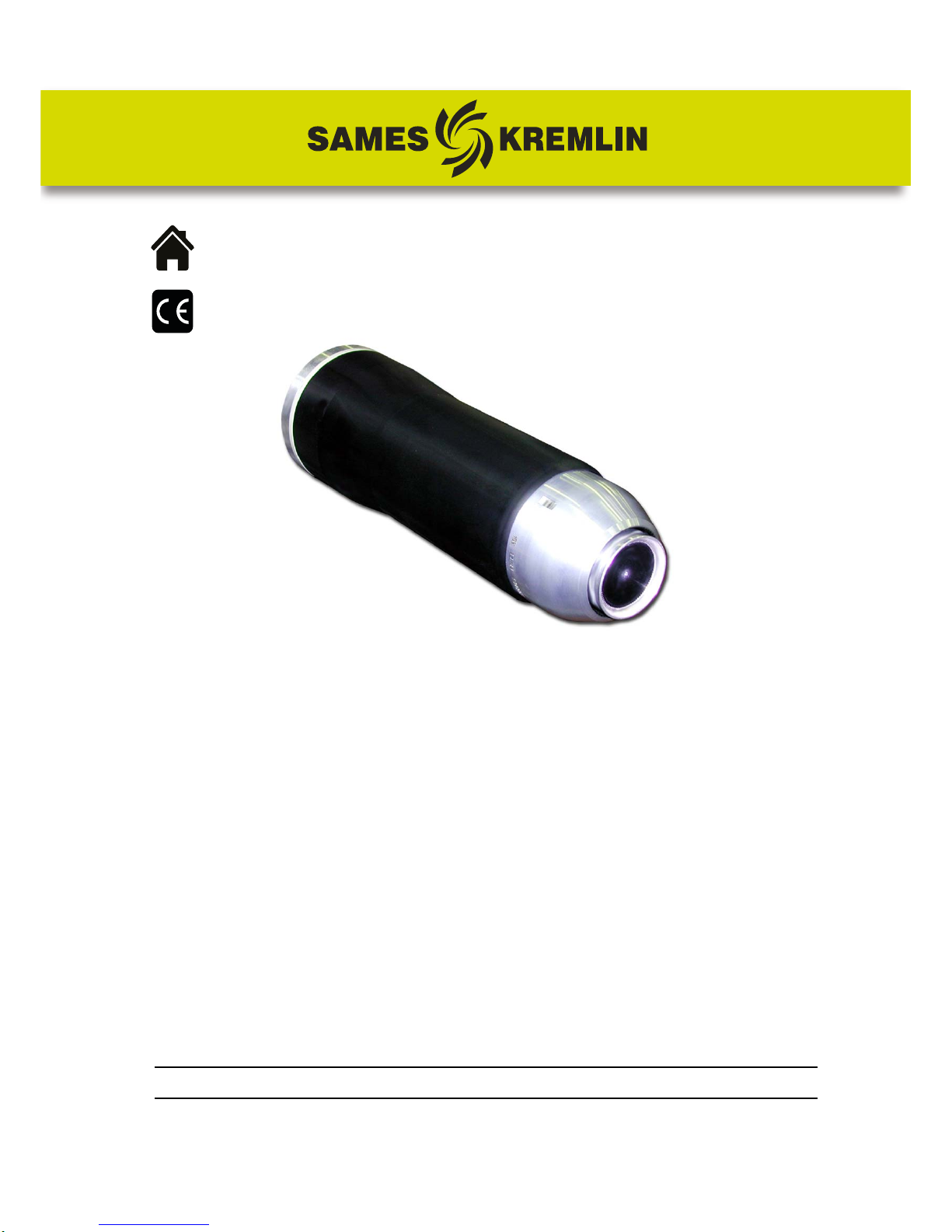

PPH 308 atomizer,

single circuit without regulator with coil

for solvented paints

1. Health and Safety Instructions - - - - - - - - - - - - - - - - - - - - - - - - - - - - 5

1.1. Configuration of the certified equipment . . . . . . . . . . . . . . . . . . 5

1.2. Marking on the atomizer . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 5

1.3. Precautions for Use . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4. Warnings . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

1.4.1. Installation rules. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

1.5. Important Recommendations . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.1. Paint Resistivity . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.2. Compressed Air Quality. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

1.5.3. Product Quality . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5.4. Bearing Safety . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5.5. Locking. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5.6. Shaping Air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5.7. High Voltage . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 11

1.5.8. Maximum Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.9. Vibrations. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.10. Bell Cup / Turbine Fitting . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.11. O-ring Seals. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.12. Ventilation . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.13. Residual pressure . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 12

1.5.14. Safety devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.15. Mechanical Collision . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.16. Ambient Temperature . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.17. Sound level . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

1.5.18. Specific maintenance provisions . . . . . . . . . . . . . . . . . . . . . . . 13

1.6. Guarantee . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

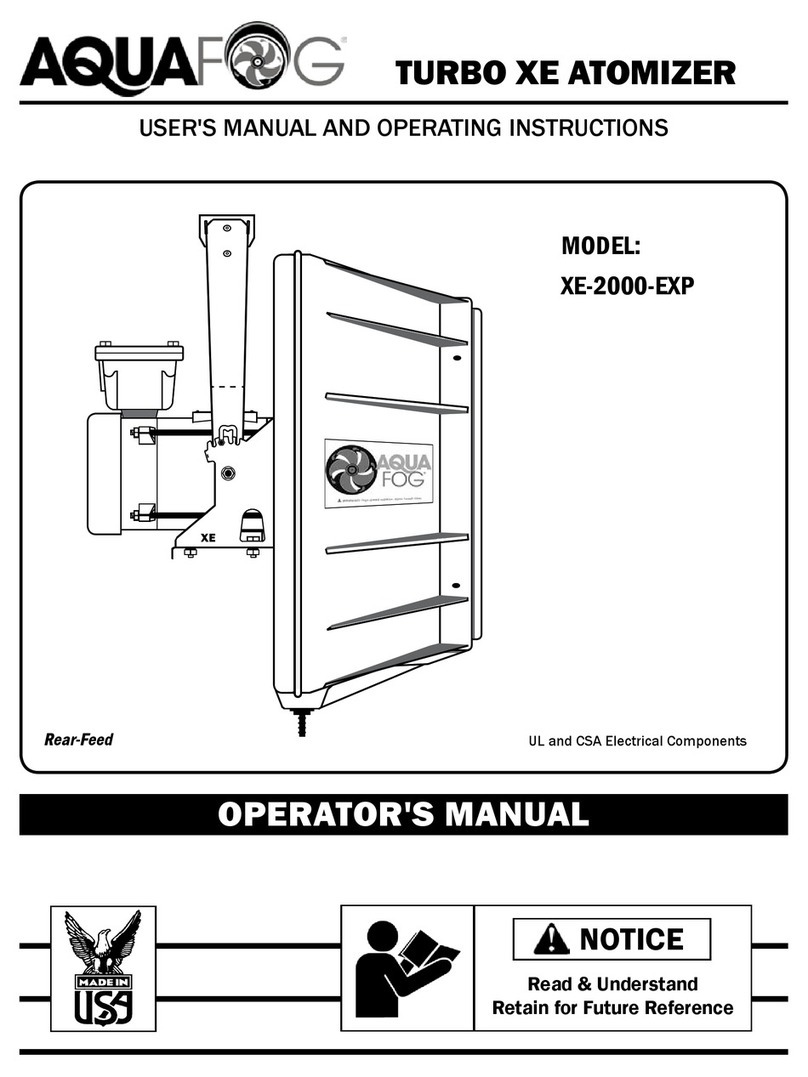

2. Description - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - 15

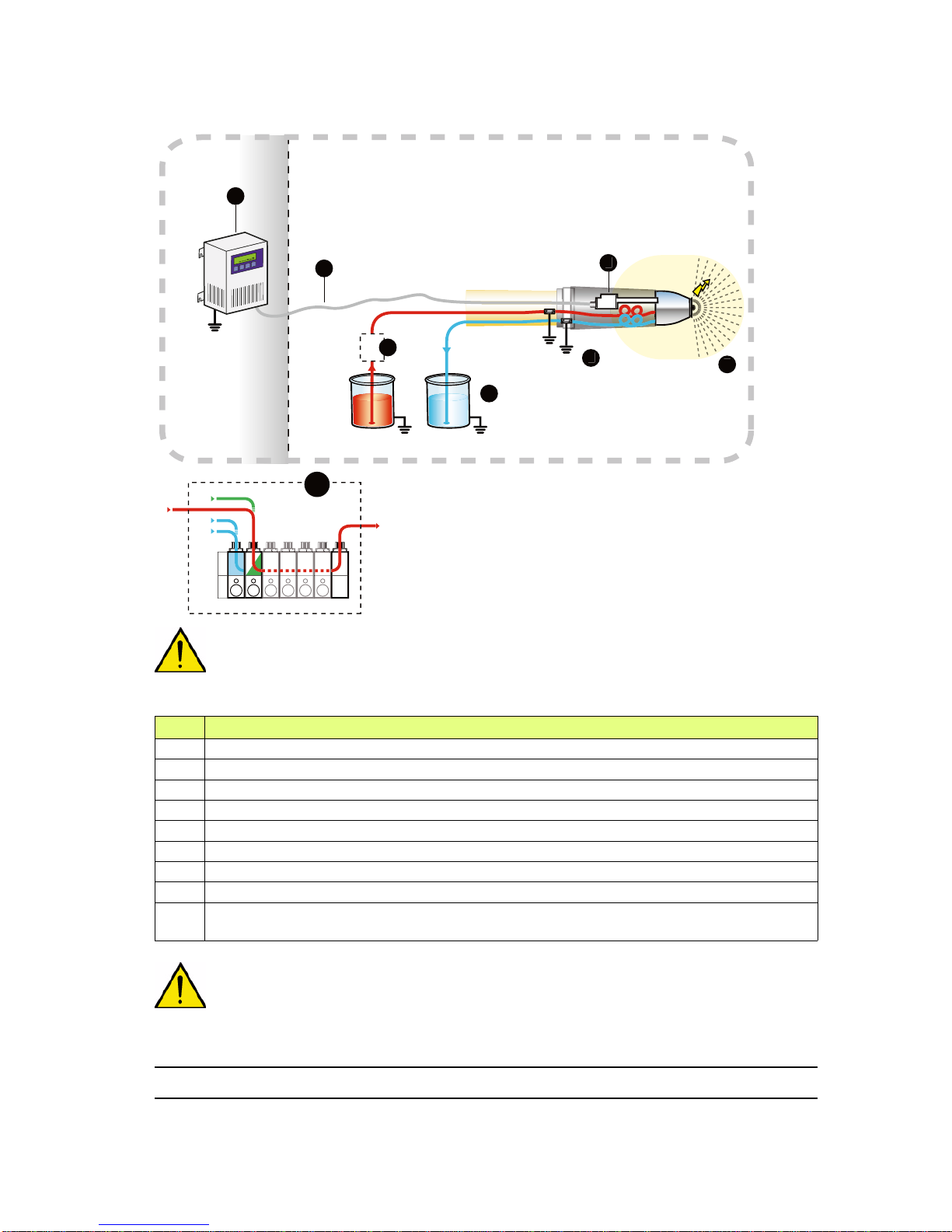

2.1. 2-Way Air / Solvent MicroValve Block (1-Pneumovalve Block) 16

2.2. High Voltage Unit UHT 155 EEx em . . . . . . . . . . . . . . . . . . . . 16

2.3. MANIFOLD block . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

2.4. Injector, injector holder, restrictor . . . . . . . . . . . . . . . . . . . . . . 16

2.5. Magnetic air bearing turbine type ”BTM” . . . . . . . . . . . . . . . . . 17

2.5.1. Turbine Rotation Speed. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.6. Shaping air . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 18

2.7. Outer Cover . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.7.1. Rinsing the external bellcup. . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

2.8. Bell cups . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

3. Characteristics of the PPH 308 Atomizer- - - - - - - - - - - - - - - - - - - - 20

3.1. Dimensions (mm) . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

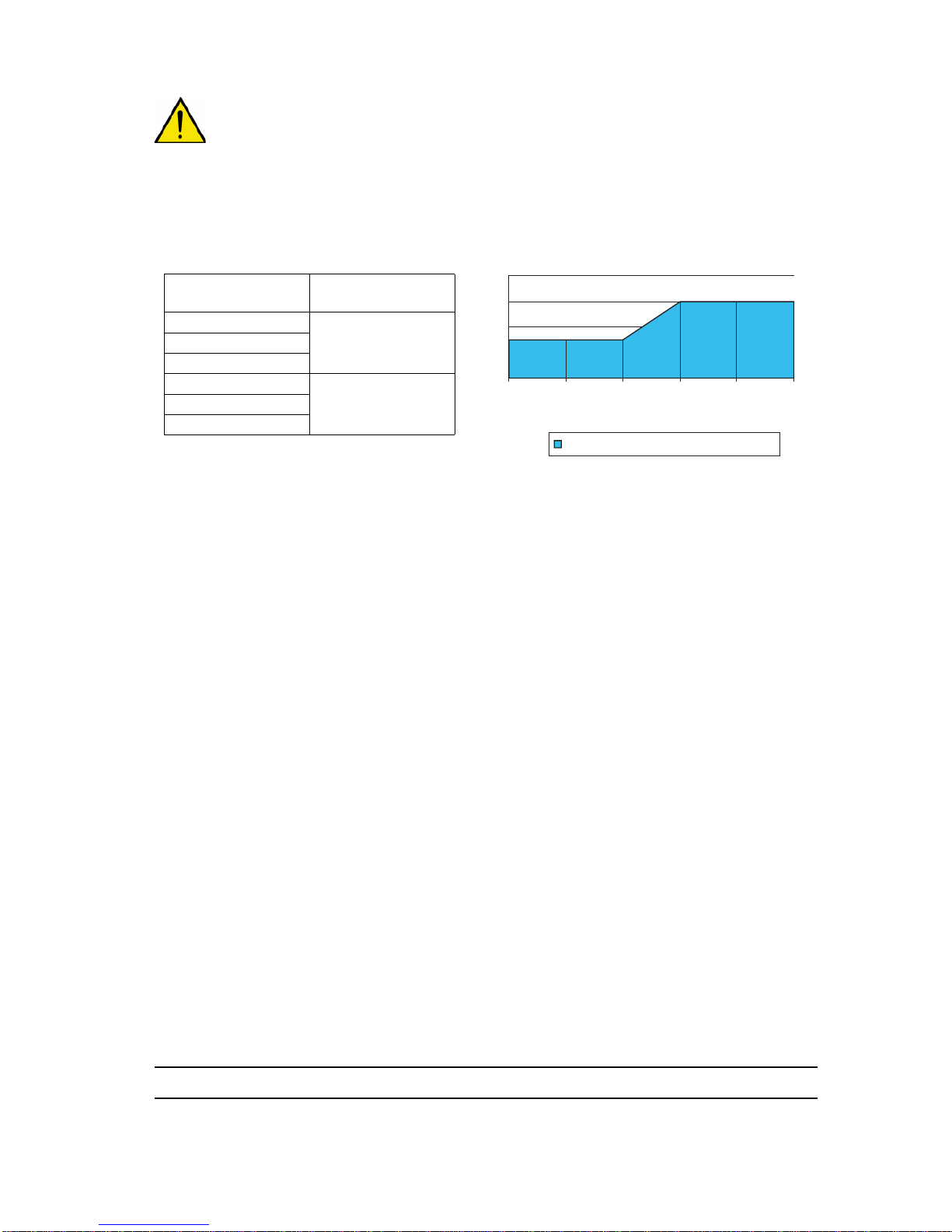

3.2. Operating characteristics . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

4. Diagram of the various fluid circuits- - - - - - - - - - - - - - - - - - - - - - - - 22

4.1. Paint diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 22