Advantages of use

Net and clear lines on any kind of pavement with

one coat only.

With a single coat the line is dened evenly: the line

made by airless spraying is linear, clean-cut and mar-

ked thanks to the at cut nozzle and without the jagged

due to the turbulences caused by air.

Reduction of Over spray.

The airless operated marking guarantees the absence

of the classic "Overspray", that is the dispersion of paint

particles which is typical in the traditional air painting.

This translates, further than in a saving of paint, in a

better protection for health of the operator and for en-

vironment.

Saving of paint up to 30%.

Thanks to the absence of Overspray almost all of the

used product is applied on the surface without any wa-

ste.

Reduction of the vibrations.

The reduction of the vibrations ensures the best in indu-

stry quality of lines.

The paint dries quickly.

The airless operation requires that ltered paint speci-

cally formulated for airless application is used, this me-

ans, by itself, even paint, smooth and uniform texture

which will not return any crust nor will become neither

jelly-like nor thick.

The paint holds tightly on any kind of pavement, with an

excellent visibility and resistance to wear caused both

by trafc and weather elements.

High quality paints guarantee a faster application

speed, a better durability of the visibility of the line and

a pleasant aesthetic result.

Reflective bead application.

Reective beats can be applied using a gravity dispen-

ser operated by the same command which operates

Larius the ideal choice for achieving

professional performance.

the paint gun. The spheres automatically fall onto the

freshly marked line. No paints with pre-mixed beads

can be used.

50 litre non-stick hopper.

Thanks to the big capacity of the hopper marking times

are extended thanks to the absence of frequent inter-

ruptions to perform colour changes.

Template works and curved marking.

The gun can be released from its support in just a few

seconds and, thanks to the 10 meters pipe it is con-

nected to, it allows any template work, on walls as well.

The front wheel helps to mark lines close to the kerb

and to mark arches and curves.

Intuitive use by the operator.

The operator commands are located right on the

handlebar to adjust the operation of the line marker in

the most handy way.

Optional equipment.

Airless line markers can be equipped basing on the dif-

ferent needs of the operator for offering a dedicated

solution for any marking need.

Easy cleaning and maintenance.

Cleaning airless line markers is quick thanks to the

absence of pressurized tanks to be cleaned and thus

colour change times are extremely short both if using

the can or the non stick paint tank. The high pressure of

the airless line marker clears the spraying area from dirt

and so it does not require that the ground is previously

cleaned.

A regular cleaning at the end of the work is sufcient to

keep the machine in perfect efciency, even after pro-

longed standing periods.

The Larius Super Fast Clean airless nozzles allow that

the nozzle is cleaned with a simple rotating movement,

without any need to detach it.

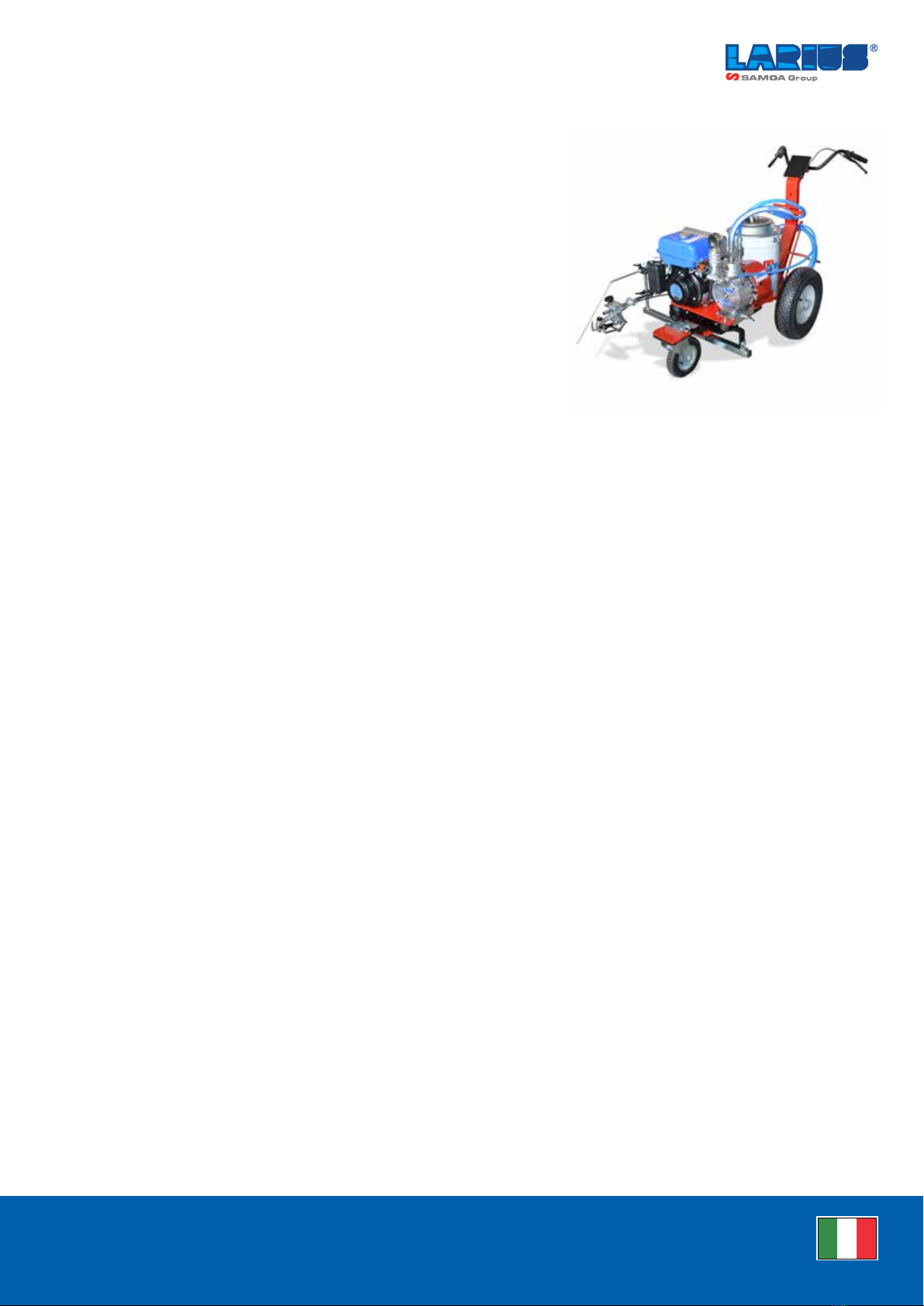

WELL PROVEN TECHNICAL QUALITY FOR ANY ON-GROUND

MARKING APPLICATION

The LARIUS airless line markers successfully join product performan-

ce with operator requirements and allow the marking and the mainte-

nance of any kind of pavement lines on roads, motorways, airports,

pedestrian crossings, cycle paths, yards and wherever is required by

the Highway Code with regards to horizontal road signs, guaranteeing

perfect lines on different surfaces.

The airless technology provides the high pressure spraying of the paint

through a nozzle having centesimal dimensions as compared to the

traditional low pressure spraying in which the paint ow is atomized

through the air contribution.

YOUR PARTNER FOR ALL YOUR MARKING NEEDS SINCE 1969