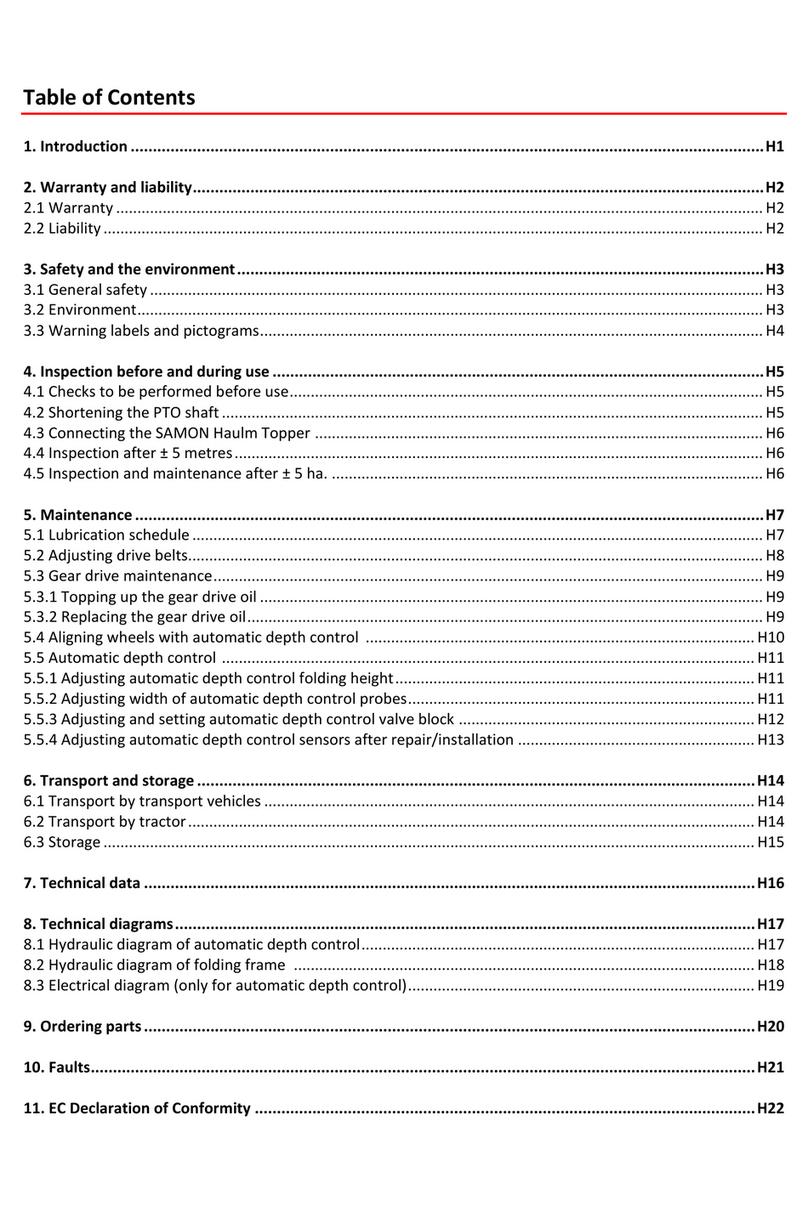

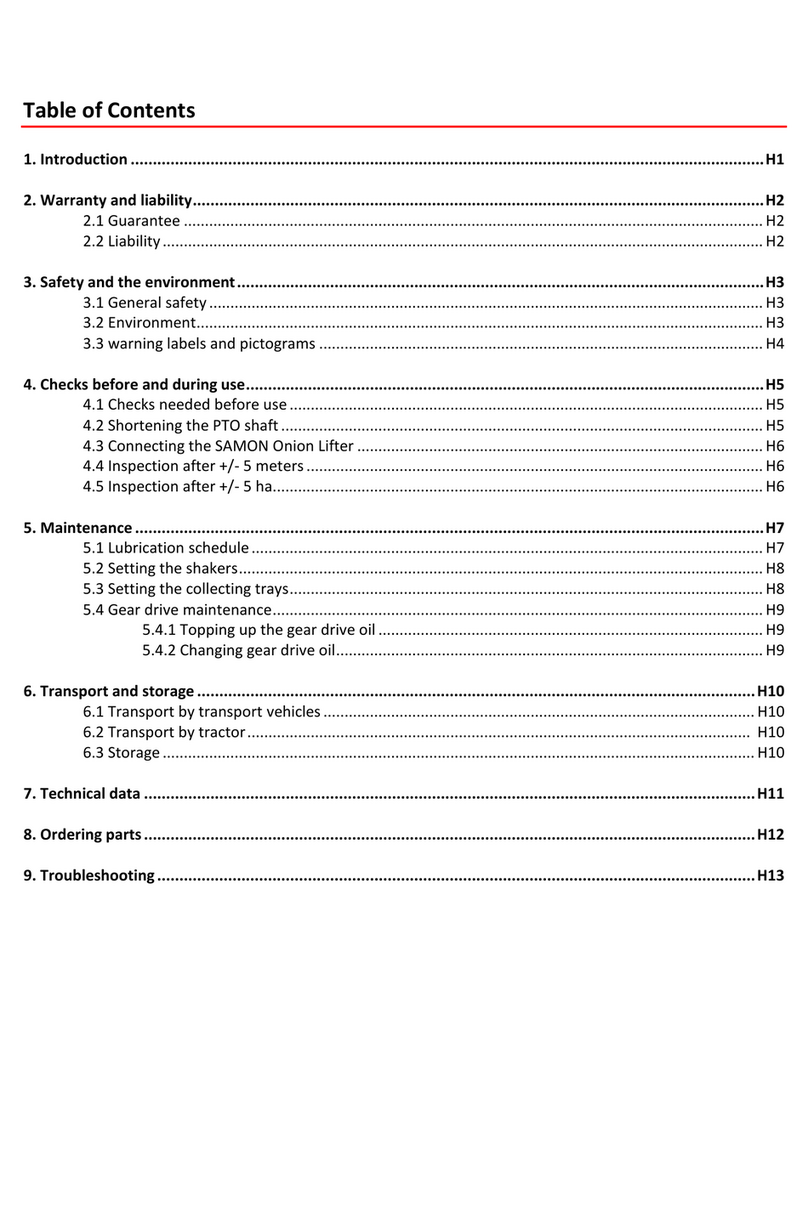

Table of Contents

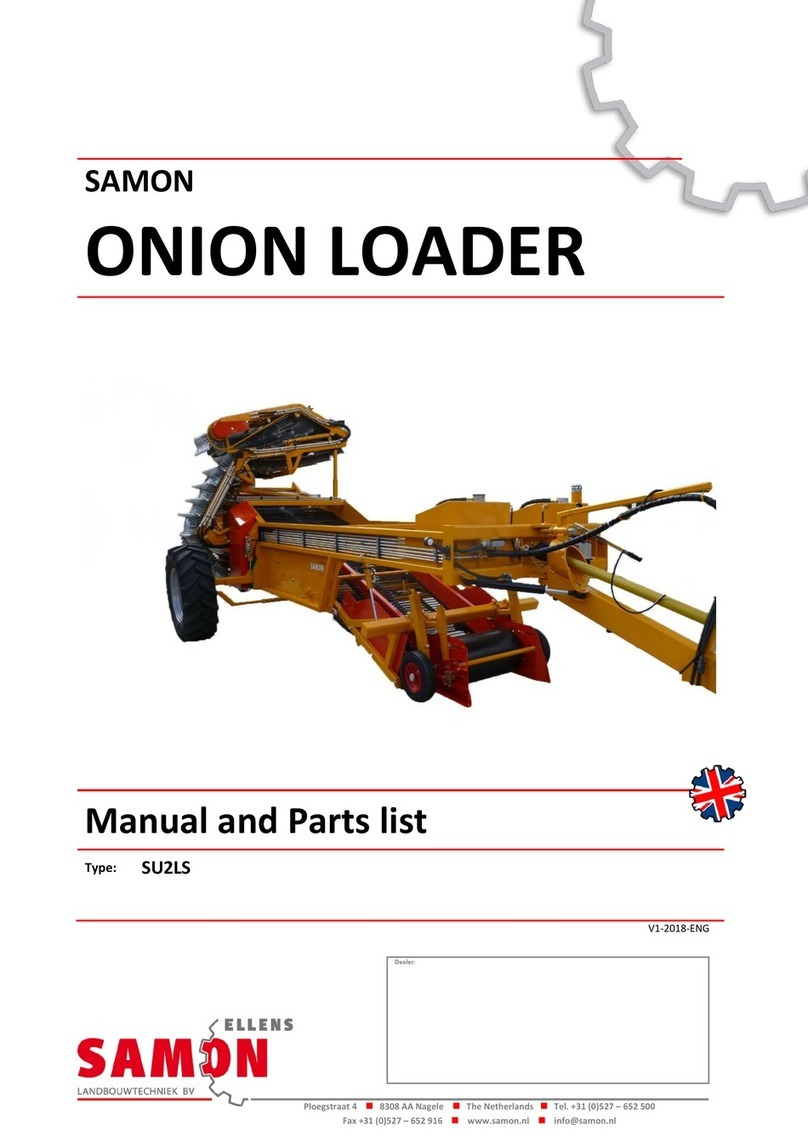

1. Introduction...................................................................................................................................................... H1

2. Warranty and liability ...................................................................................................................................... H2

2.1 Warranty ........................................................................................................................................... H2

2.2 Liability .............................................................................................................................................. H2

3. Safety and environment................................................................................................................................... H3

3.1 General safety ................................................................................................................................... H3

3.2 Environment...................................................................................................................................... H3

3.3 Warning labels and pictograms......................................................................................................... H4

4. Checks before and during use .......................................................................................................................... H5

4.1 Checks needed before use ................................................................................................................ H5

4.2 Checks needed during use ................................................................................................................ H5

5. Operating.......................................................................................................................................................... H6

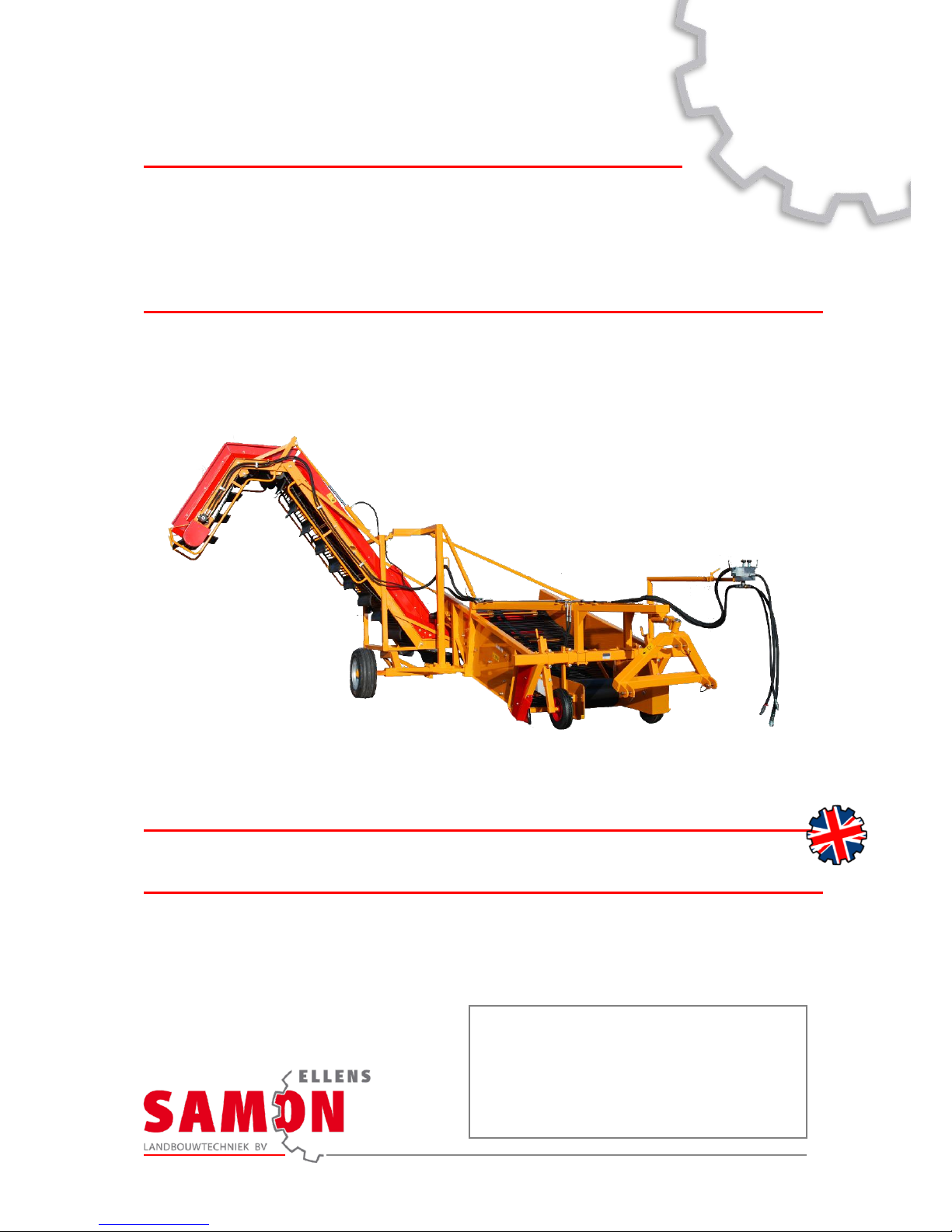

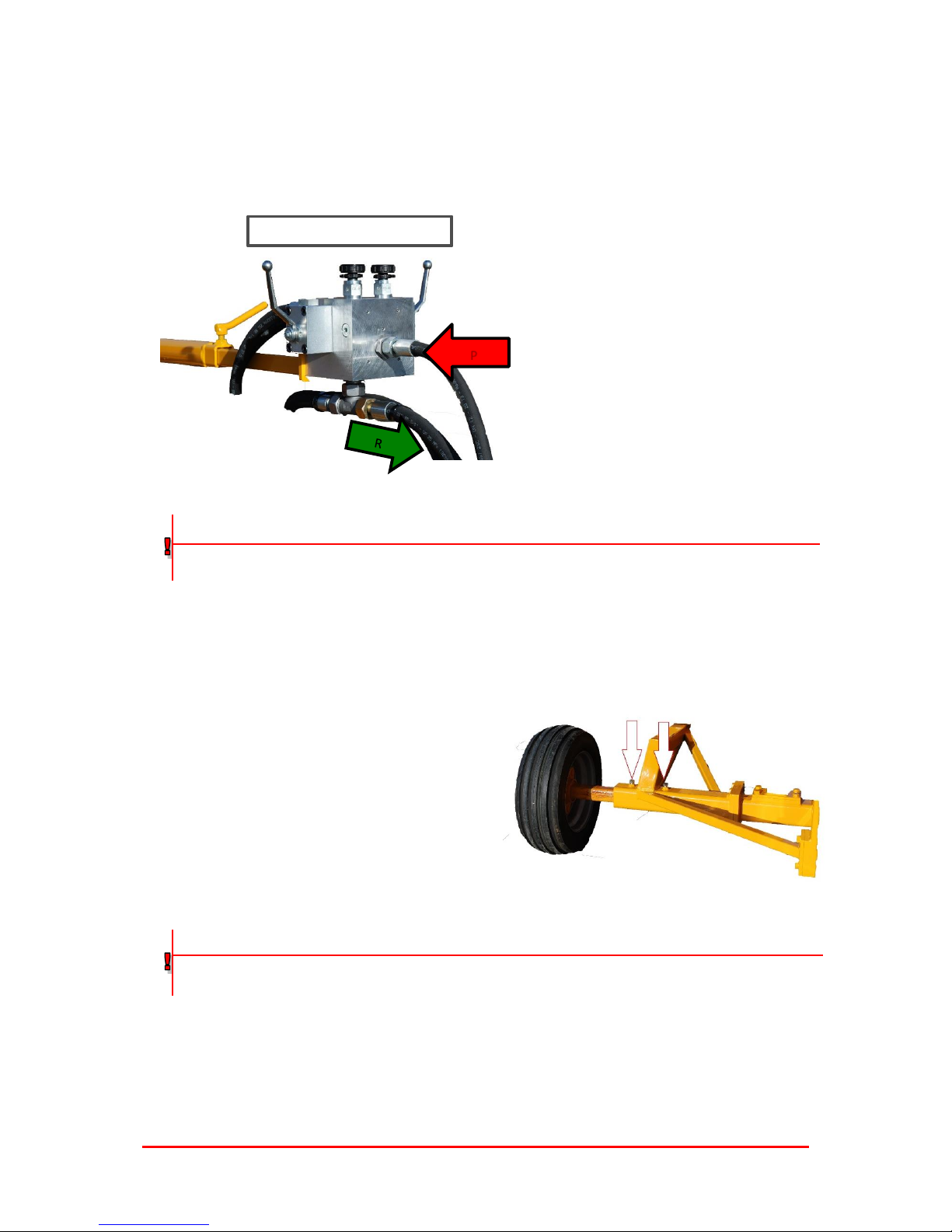

5.1 Connecting the SAMON Onion loader and setting sieve/elevator belt speed.................................. H7

5.2 Setting wheel track ........................................................................................................................... H6

6. Maintenance..................................................................................................................................................... H7

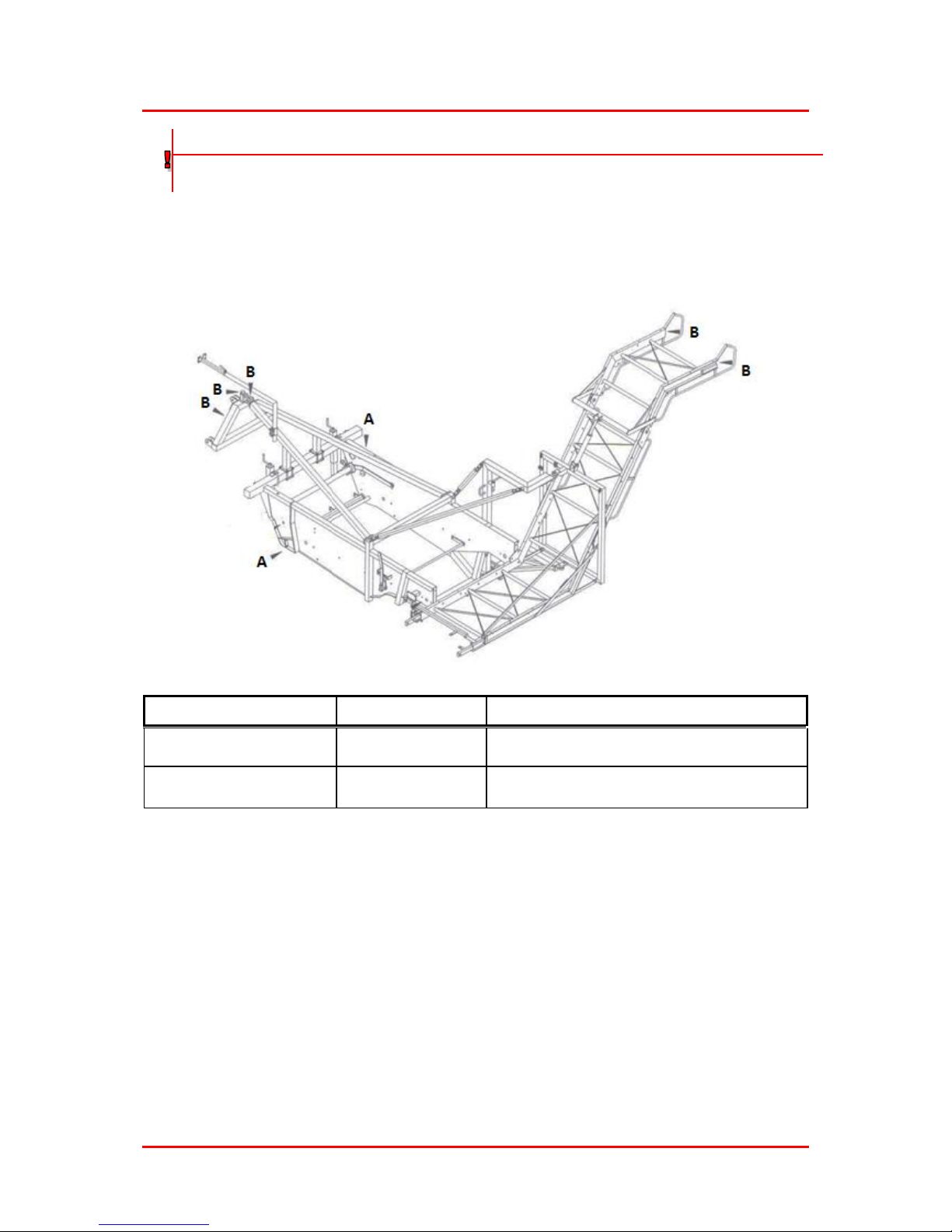

6.1 Lubricating schedule ......................................................................................................................... H7

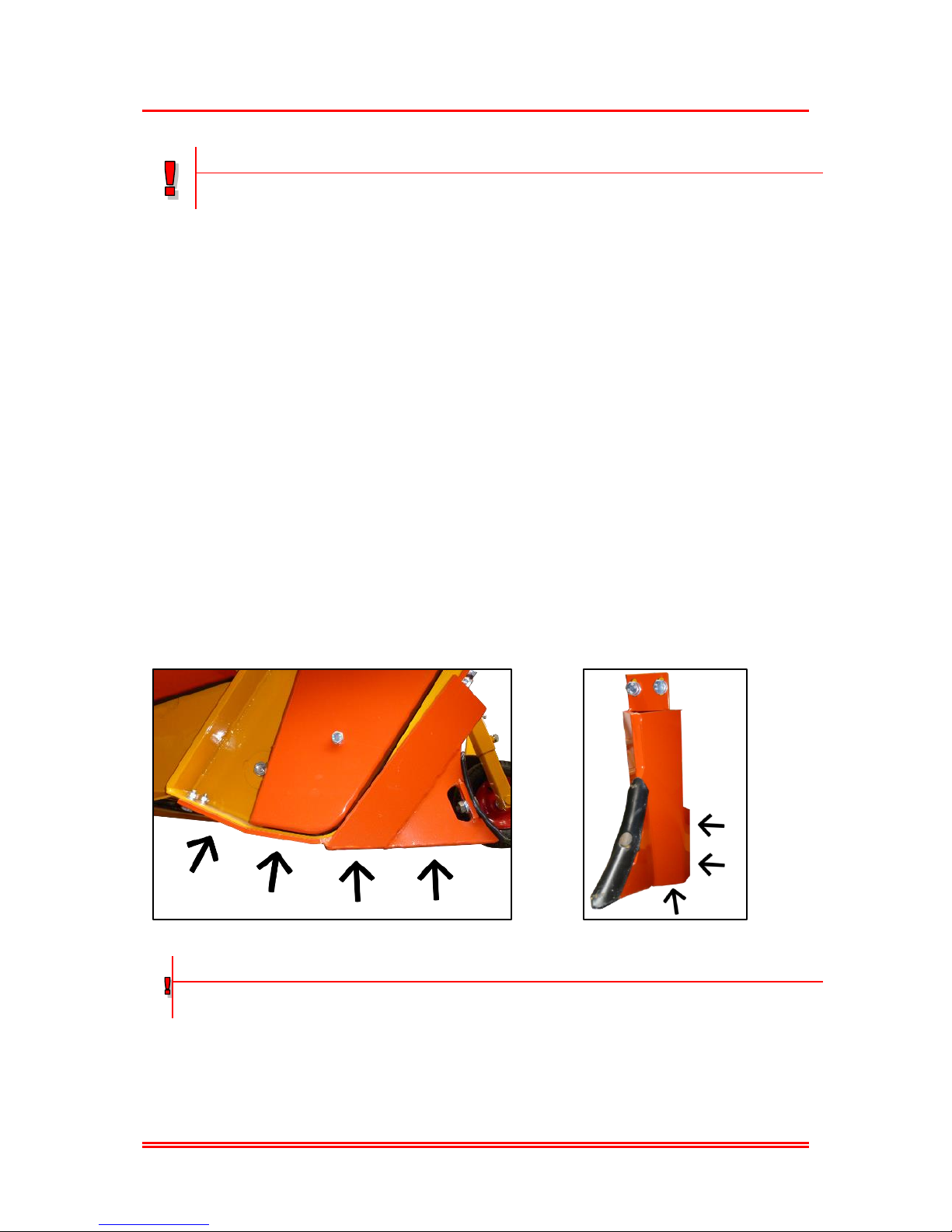

6.2 Tensioning elevator belt ................................................................................................................... H8

7. Transport and storage ...................................................................................................................................... H9

7.1 Placing the elevator into loading/transport position........................................................................ H9

7.2 Transport by transport vehicles ...................................................................................................... H10

7.2 Transport by tractor ....................................................................................................................... H10

7.3 Storage ............................................................................................................................................ H10

8. Technical data................................................................................................................................................. H11

9. Ordering parts ................................................................................................................................................ H12

10. Troubleshooting ........................................................................................................................................... H13

11. EG declaration of conformity ....................................................................................................................... H14