P A G E | 4

Wintex Agro, Vilhelmsborgvej 15, DK-7700 Thisted

+45 97990800, contact@wintexagro.com, www.wintexagro.com

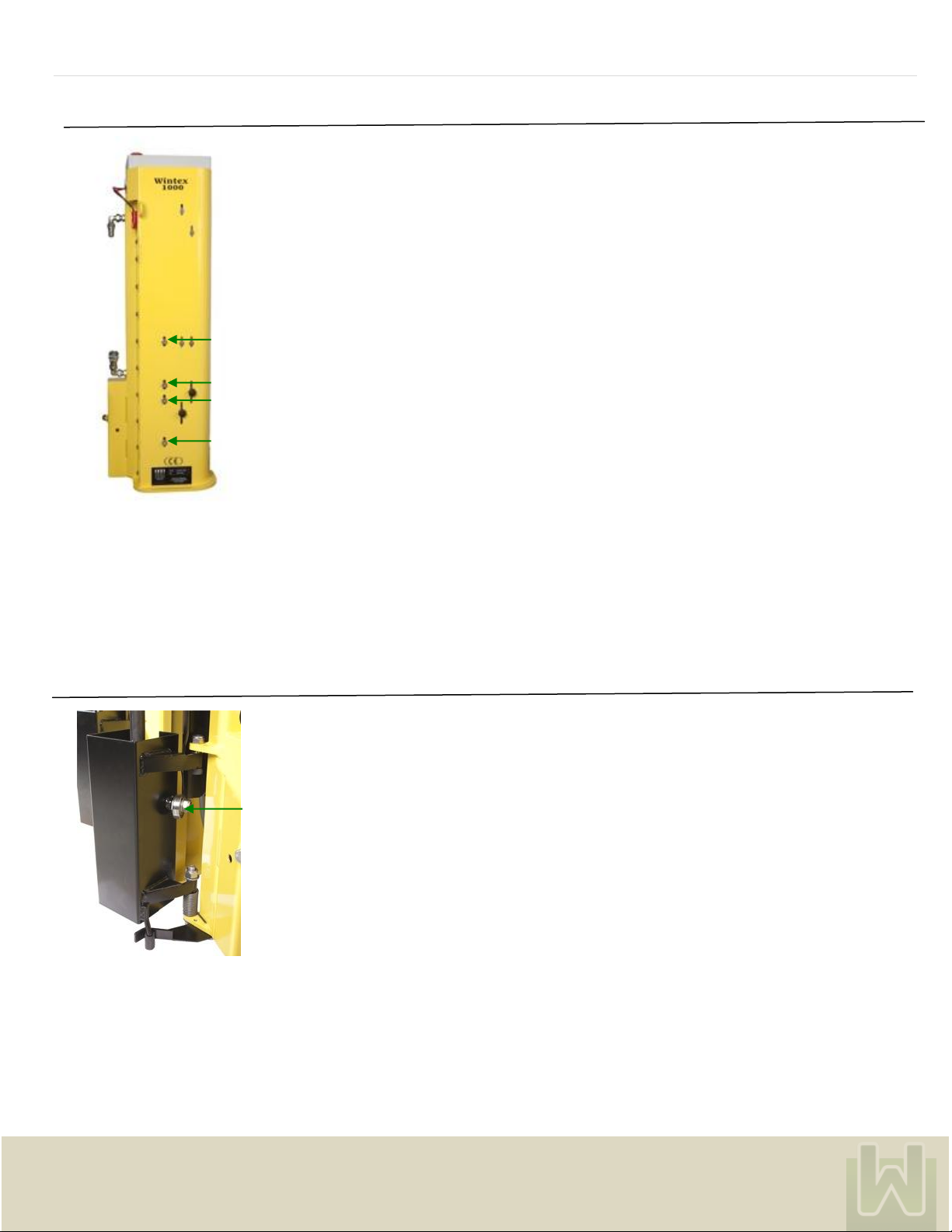

4. ADJUSTMENT OF PROBE DEPTH

The probe can penetrate soil up to 25 cm. To adjust the depth, loosen the star knobs and move the

sensor up or down.

If further adjustment is necessary, the yellow unit can be moved in the holes of the mounting frame.

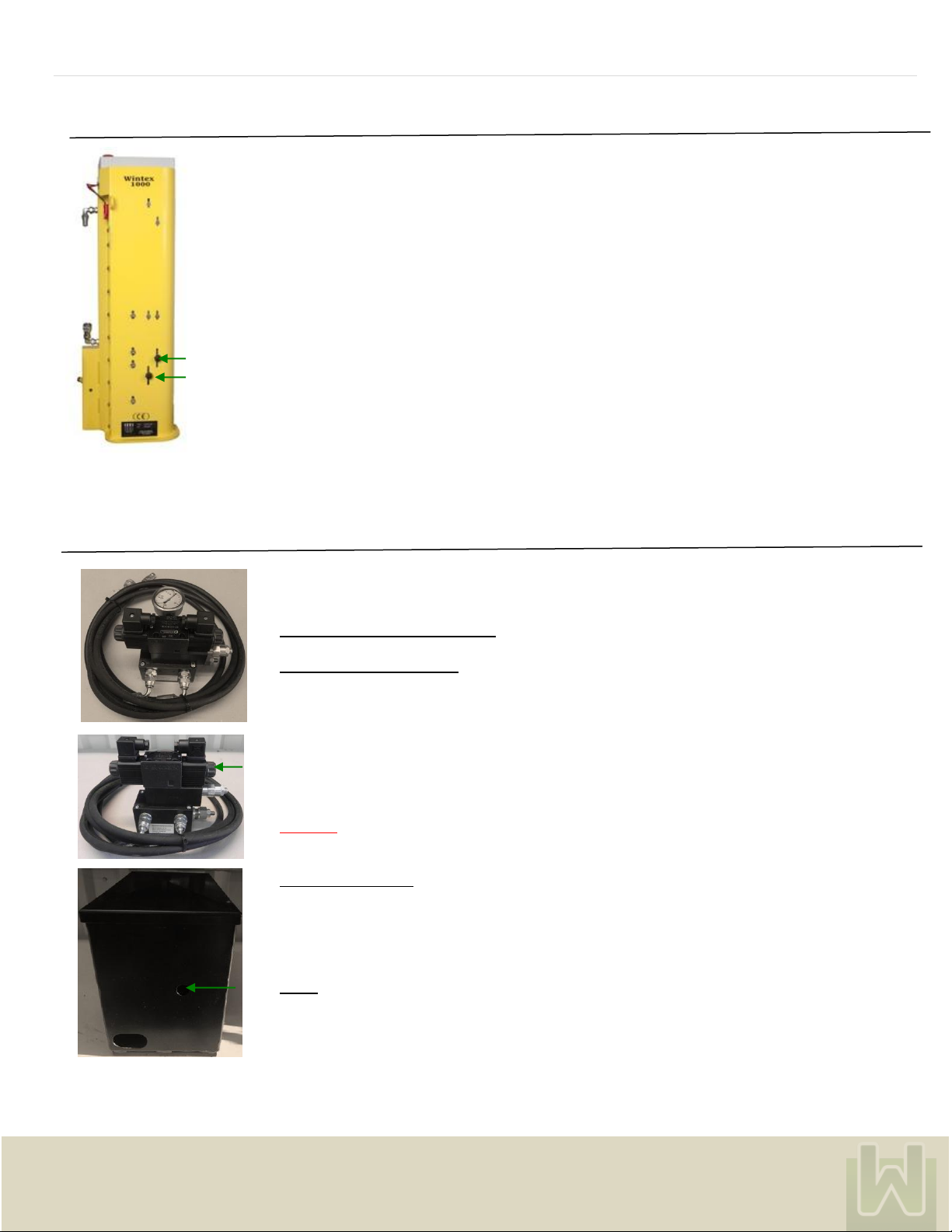

5. ADJUSTMENT OF OIL PRESSURE

The oil pressure is pre-set at a lower limit of 50 bar and an upper limit of 80 bar. Adjusting

the excess pressure valve can alter the pressure.

For adjusting the pressure downwards loosen the lock nut with a 19 mm key, and adjust the screw

with a 6 mm Allen key. Increase the pressure by turning the screw clockwise.

To adjust the pressure upwards loosen the locknut with a 17 mm key, and adjust the screw with a

5 mm Allen key. Increase the pressure by turning the screw clockwise.

Read the pressure directly on the mounted pressure gauge.

The soil sampler can also be activated manually. Push the rubber button (see arrow) in the hole at

the front of the oil tank, and the probe will move up. Push the button on the opposite side (see

arrow), and the probe will go down.

Important:

The lower pressure must not exceed 50 bar or the soil sampler will be damaged!

Filling with hydraulic oil:

Remove the screw lid at the top of the oil tank and replenish with hydraulic oil.

Important: Do only use DIN HLP 22 or 32 oil! The WINTEX 1000 is pre-filled with Equivis ZS32

hydraulic oil.

Fuses:

There are two fuses in the control box: one 25 amp fuse for the rotation of the probe (on the latest

models a 15 amp fuse) and one 7.5 amp fuse for current control.