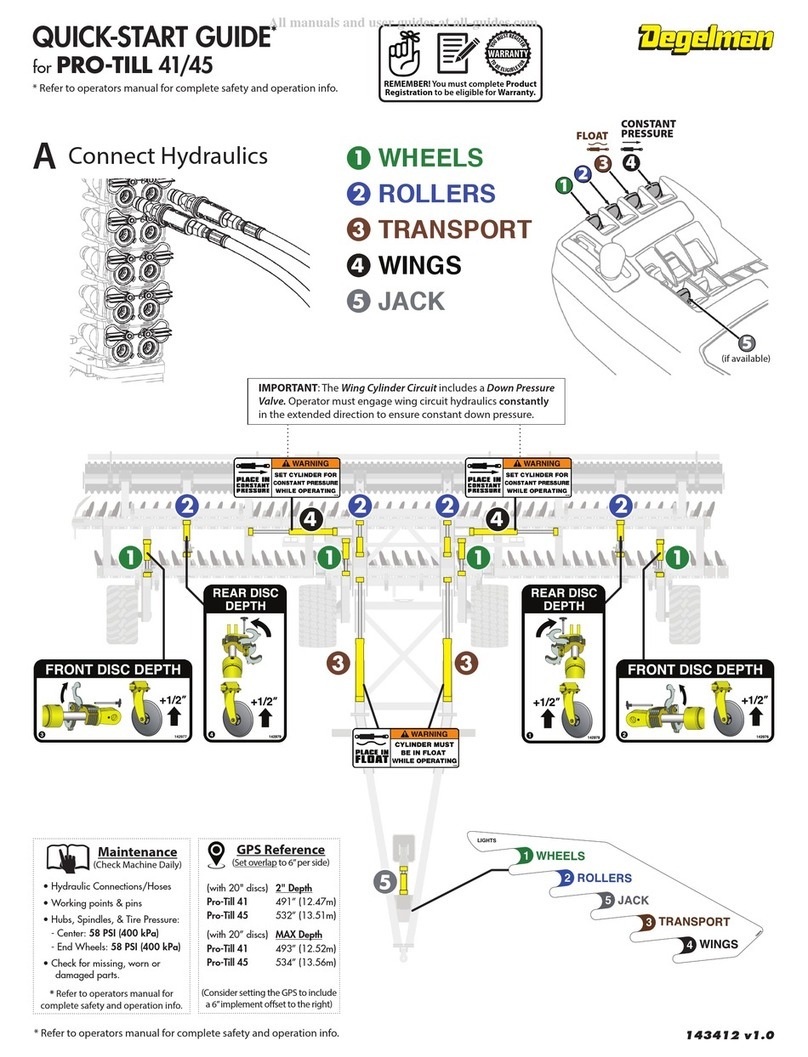

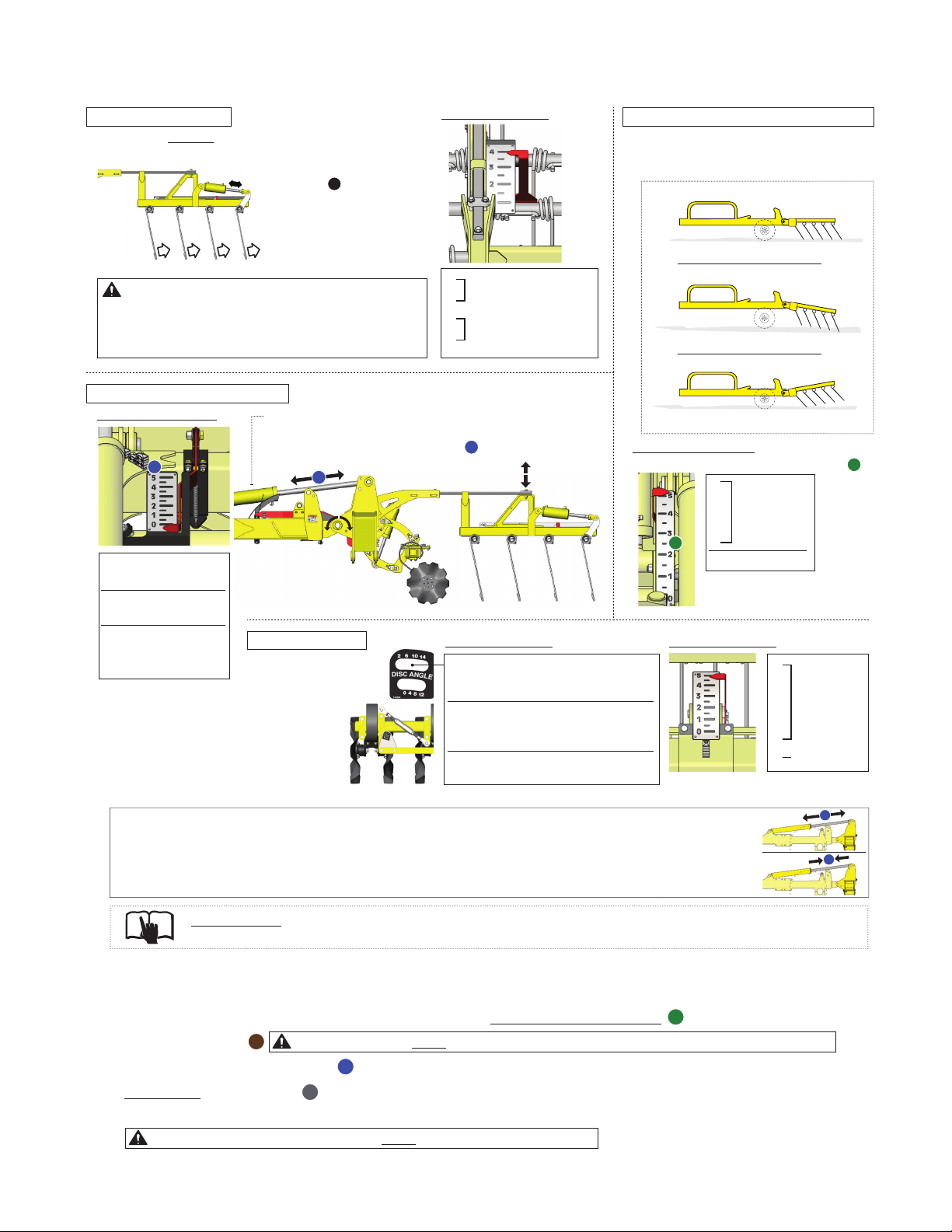

Center Beam Torque Adjustment

CSetting Tine Angle, Pressure, Frame, & Disc Angle

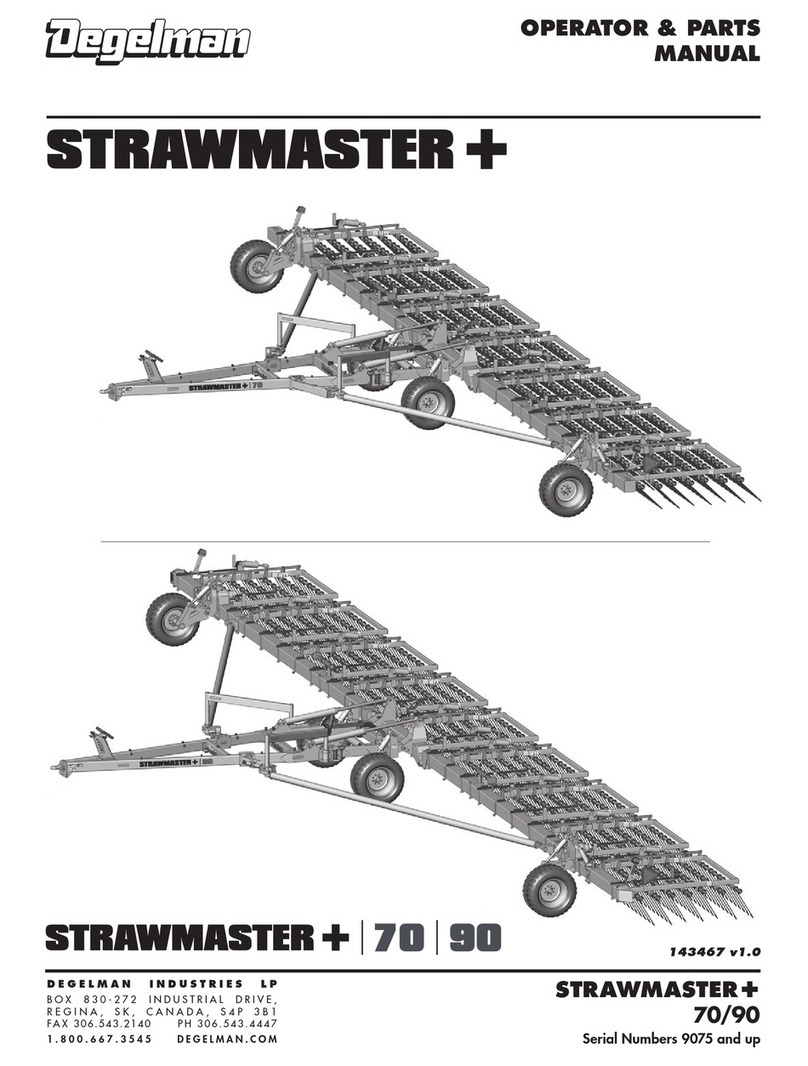

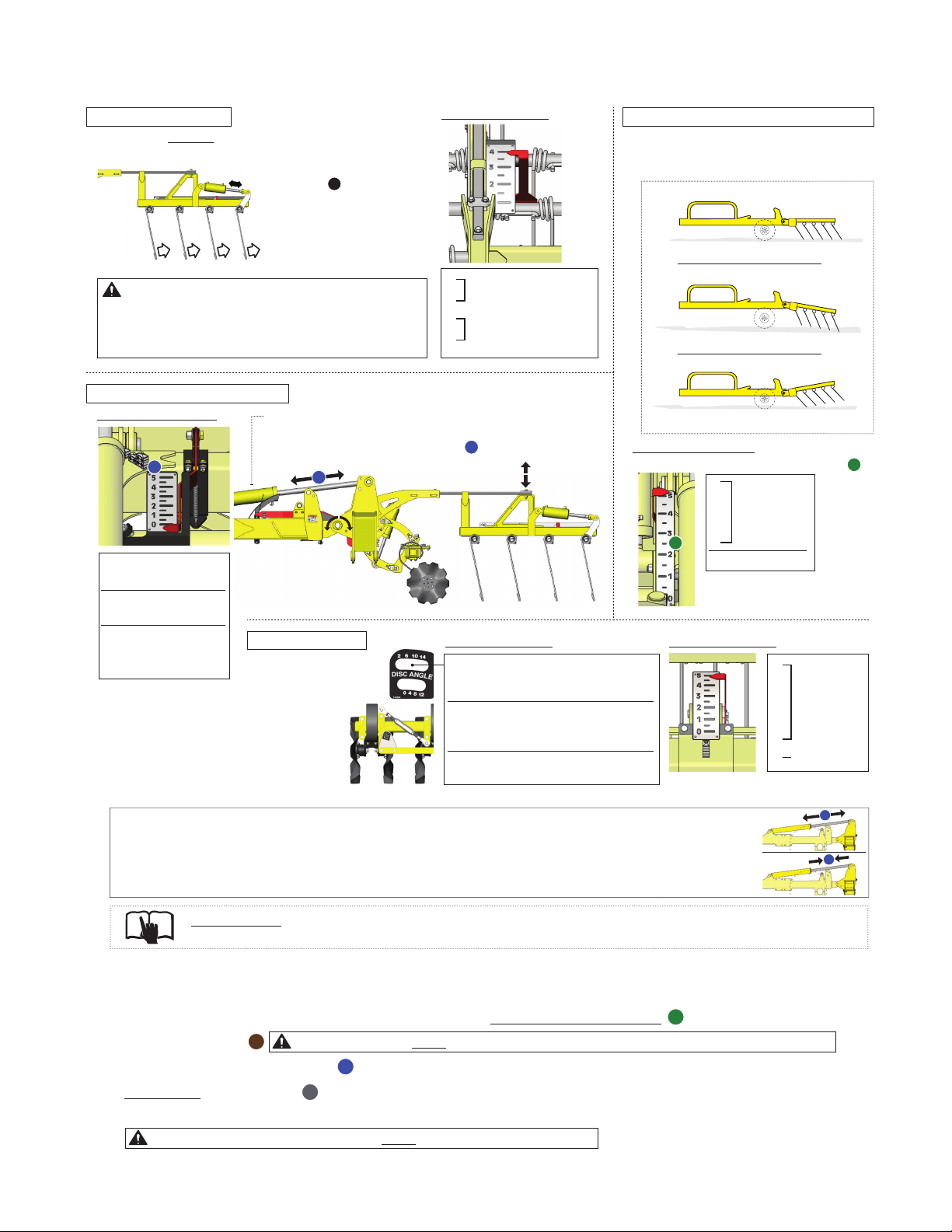

• Straw should be dry.

• A speed of 8 to 12 MPH (12 to 16 KPH) is suggested to

efficiently shatter and spread straw and residue.

• If discing aggressively, DO NOT have much straw in

harrow sections.

Remember When Operating:

• If machine leaves small clumps of straw, apply slight

down pressure by extending Transport cylinders.

• If machine leaves large clumps of straw, reduce

down pressure by retracting the Transport cylinders

and reducing the tine angle.

2

2

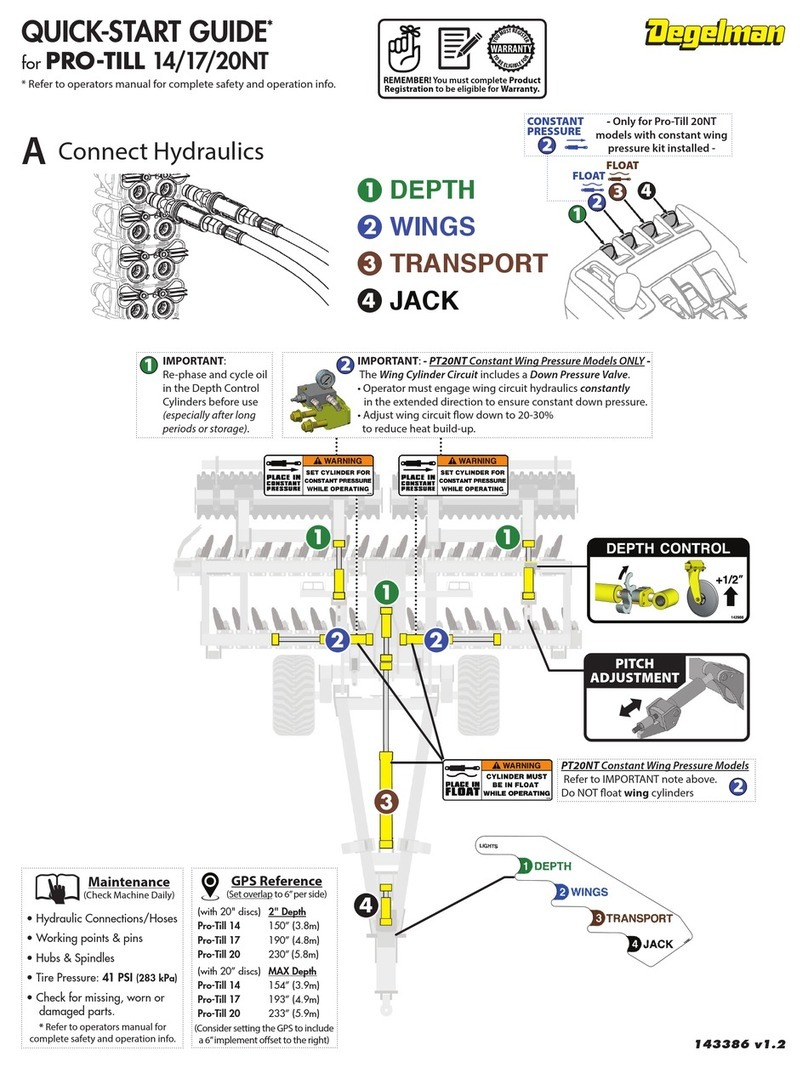

Tine Angle Adjustment

IMPORTANT: Re-syncronize the tine section cylinders

by fully extending the rephasing cylinders and holding

for 30 seconds. This should be repeated a few times

daily or as needed, especially in hilly conditions.

- Refer to manual for more information. -

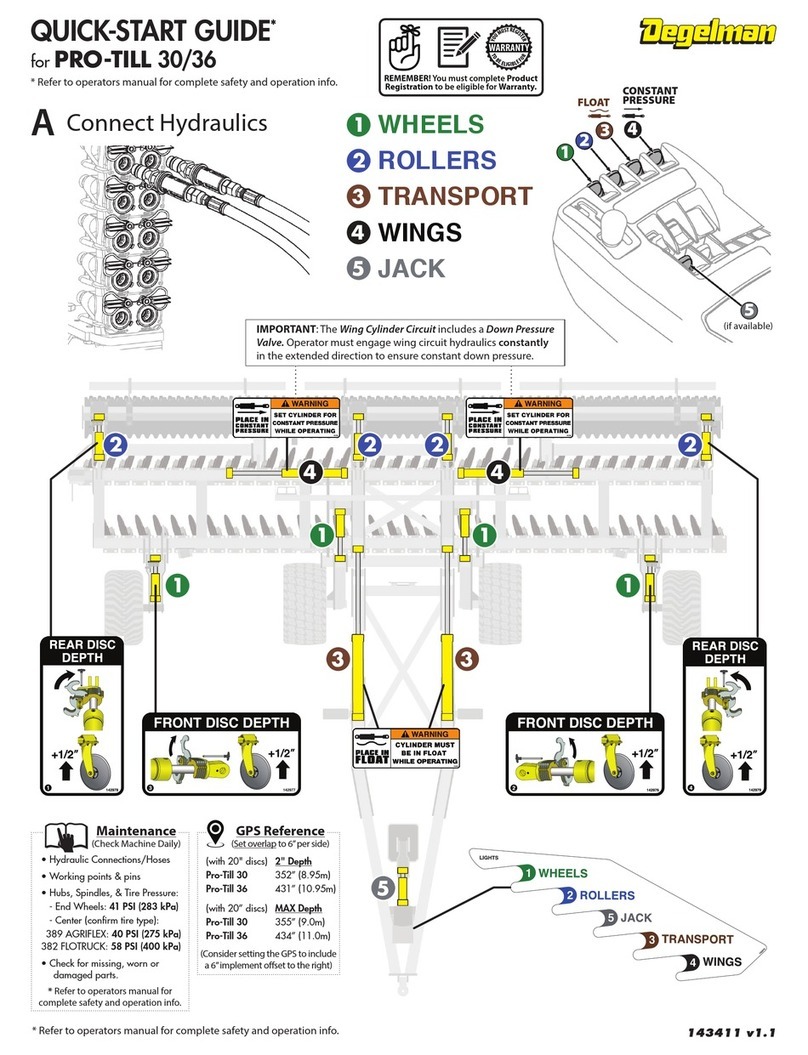

• Check for missing, worn or damaged parts.

• Working points & pins • Grease Endwheel Turrets (25hrs)

Maintenance

(Check Machine Daily)

• Hydraulic Connections & Hoses

• Hubs & Spindles

* Refer to operators manual for complete safety and operation info.

• Tire Pressure:

41 PSI (283 kPa)

There are no standard angles for running the tines, the operator

may adjust the tine angles as needed to achieve desired results.

Note: Actual settings will vary

with tine wear. Ensure trailer and

frame are leveled properly.

(Refer to Height Adjustment)

- Retract rephasing tine angle

cylinders to raise tines.

- Extend cylinders to lower.

4

Beam Torque Indicator

DMoving Into Transport Position

1) When placing machine into Transport position, keep the Trailer Height at Maximum.

2) Raise disc sections. IMPORTANT: Discs MUST be raised. Failure to do so will result in damage to disc sections.

3) Operate the transport hydraulics to fully raise the harrow sections.

4) Fully Rotate the endwheels before driving forward. The wing beams should fold back into transport position.

5) Install all frame transport pins (2), cylinder lock bars (2), and endwheel transport bars (2).

IMPORTANT: Endwheel transport bars MUST be installed during transport.

6) Ensure SMV sign and reectors are clean and lights are working. Follow all local transport laws when transporting.

2

5

1

3

2

NOTE: “0” indicates fully

raised & “5” is lowest height.

Adjusted with“Wheel Height Cylinders”. 1

5

4

3

2

1

0

Adjust

According to

Tine Angle

Setting

- Transport

Trailer Height Indicator

1

After Tine Angle Adjustment is complete, adjust

wheel height until trailer frame is parallel to the

ground. If needed, clevis height may be adjusted.

Trailer & Wing Beam Height Adjustment

When set level with harrows...

Front & back tines apply equal pressure

Front tines applying more pressure

When set lower...

Front tines apply less pressure

When set higher...

Tine Angle Indicator

4

3

2

1

Chemical Incorporation

or Light Tillage

Harrowing in wet

conditions or

Discing in Sloughs

NOTE: The applied beam torque shown on the

indicator is adjusted by applying (+) or reducing (–)

pressure with the Transport Cylinders. 2

2+

–

~

–

+

Setting Disc Angle

- Loosen Jam Nuts.

- Adjust Turnbuckle.

- Re-tighten Jam Nuts.

0°-4° with a coulter disc will allow you

to open the ground and cut trash with

minimal soil disruption.

5°-7° is good for mixing some dirt with

residue while loosening the soil but still

leave stubble standing to catch snow.

8°-10° is perfect for working low spots

with high trash and for drying them out.

Disc Angle Indicator Disc Depth Indicator

5

4

3

2

1

0

Adjust

According to

Cart Height

& Disc Depth

Required.

Transport

(For minimal tillage, use in float.)

(Each disc section

is adjusted

independantly.)

5

4

3

2

1

0

Maximum Pressure

(Light Tillage)

Minimum Pressure

(Spread Chaff

& Residue)

Normal Harrowing