Contents

EB 4749 EN

1 Safety instructions and measures ................................................................1-1

1.1 Notes on possible severe personal injury ......................................................1-3

1.2 Notes on possible personal injury ................................................................1-4

1.3 Notes on possible property damage.............................................................1-5

2 Markings on the device ..............................................................................2-1

2.1 Nameplate .................................................................................................2-1

2.2 Article code................................................................................................2-2

3 Design and principle of operation ...............................................................3-1

3.1 Device overview and operating controls........................................................3-1

3.2 Technical data ............................................................................................3-2

3.3 Dimensions in mm.......................................................................................3-5

4 Shipment and on-site transport ...................................................................4-1

4.1 Accepting the delivered goods .....................................................................4-1

4.2 Removing the packaging from the position transmitter....................................4-1

4.3 Transporting the position transmitter .............................................................4-1

4.4 Storing the position transmitter.....................................................................4-1

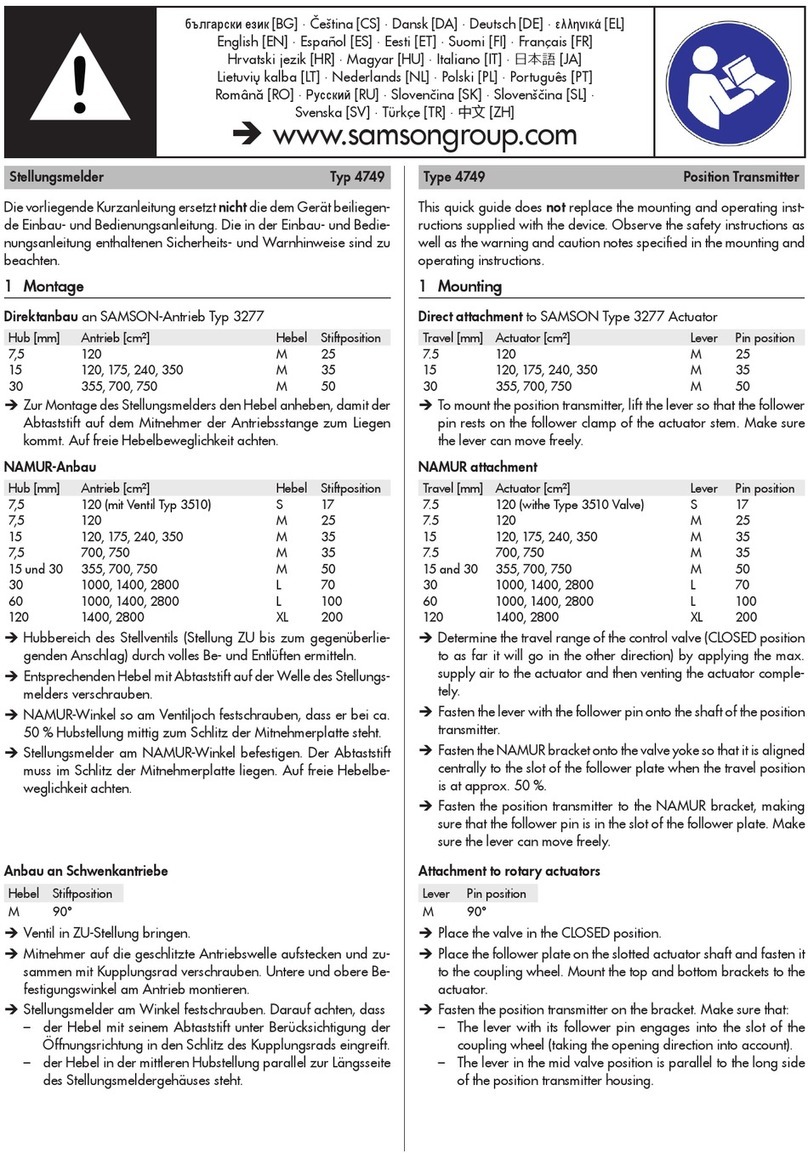

5 Installation.................................................................................................5-1

5.1 Installation conditions..................................................................................5-1

5.2 Preparation for installation...........................................................................5-2

5.2.1 Lever and pin position .................................................................................5-2

5.3 DirectattachmenttoType3277andType3277-5Actuators...........................5-4

5.4 AttachmentaccordingtoIEC60534-6(NAMURrib) .....................................5-6

5.5 AttachmenttoType3510Micro-owValve ...................................................5-8

5.6 AttachmenttorotaryactuatorsaccordingtoVDI/VDE3845 ........................5-10

5.6.1 Lightversion .............................................................................................5-10

5.6.2 Heavy-dutyversion ...................................................................................5-12

5.7 Establishingelectricalconnections ..............................................................5-14

5.8 Mounting accessories ................................................................................5-17

6 Operation..................................................................................................6-1

6.1 Operatorkeysandmenustructure................................................................6-1

6.2 Lockingtheconguration.............................................................................6-3

7 Start-up .....................................................................................................7-1

7.1 Determiningthemountingsituation ..............................................................7-2

7.2 Determiningthepositionat4mA.................................................................7-2

7.2.1 Determiningthepositionat20mA...............................................................7-3

7.2.2 Issuingatestcurrent....................................................................................7-4