6

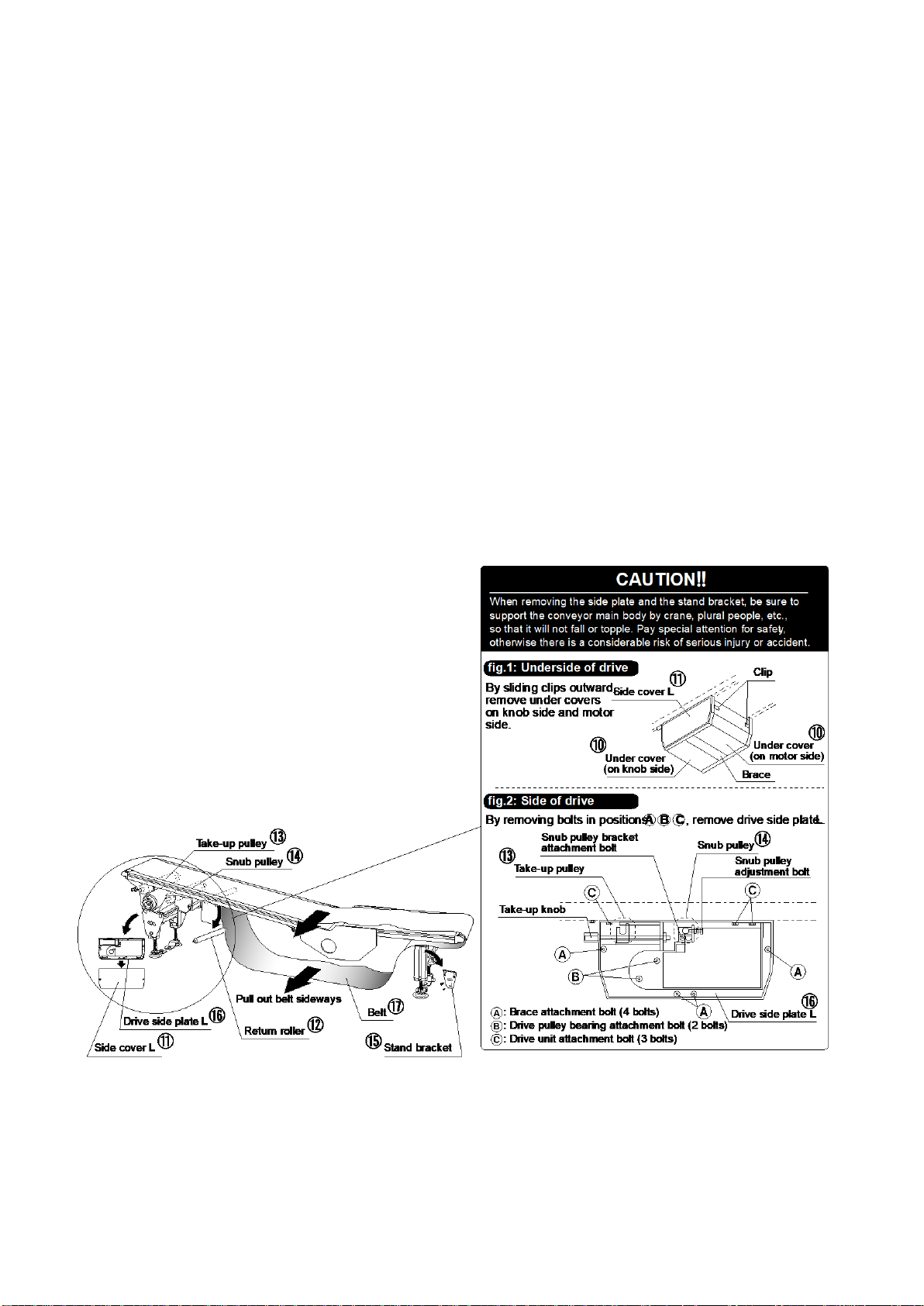

2. BELT REPLACEMENT OF HEAD DRIVE TYPE SCLV MODEL

⑩Remove side cover.

⑪Remove side plate in order below:

⑪-A Remove fixing plate attachment bolt (1 bolt on side plate).

⑪-B Remove side plate attachment bolts (2 bolts).

⑪-C Remove brace attachment bolts (2 bolts).

⑪-D Remove stand attachment bolts (2 bolts).

NOTE: For single-support drive or side-mount drive, skip step ⑪ because these

have no side plate.

⑫Remove return roller.

⑬Remove stand bracket. (By steps ⑩ to ⑬, clearance to pull out belt is made.)

⑭Pull out belt sideways, and install replacement belt.

NOTE: When installing replacement belt, confirm direction of belt travel written

on belt undersurface.

⑮Reinstall all the removed parts. Take up the belt and make belt alignment

adjustment, referring to “S-CON®MINI Series Operating and Service

Manual”, p.23-27.