1

HZ1878-E

Precautions during installation

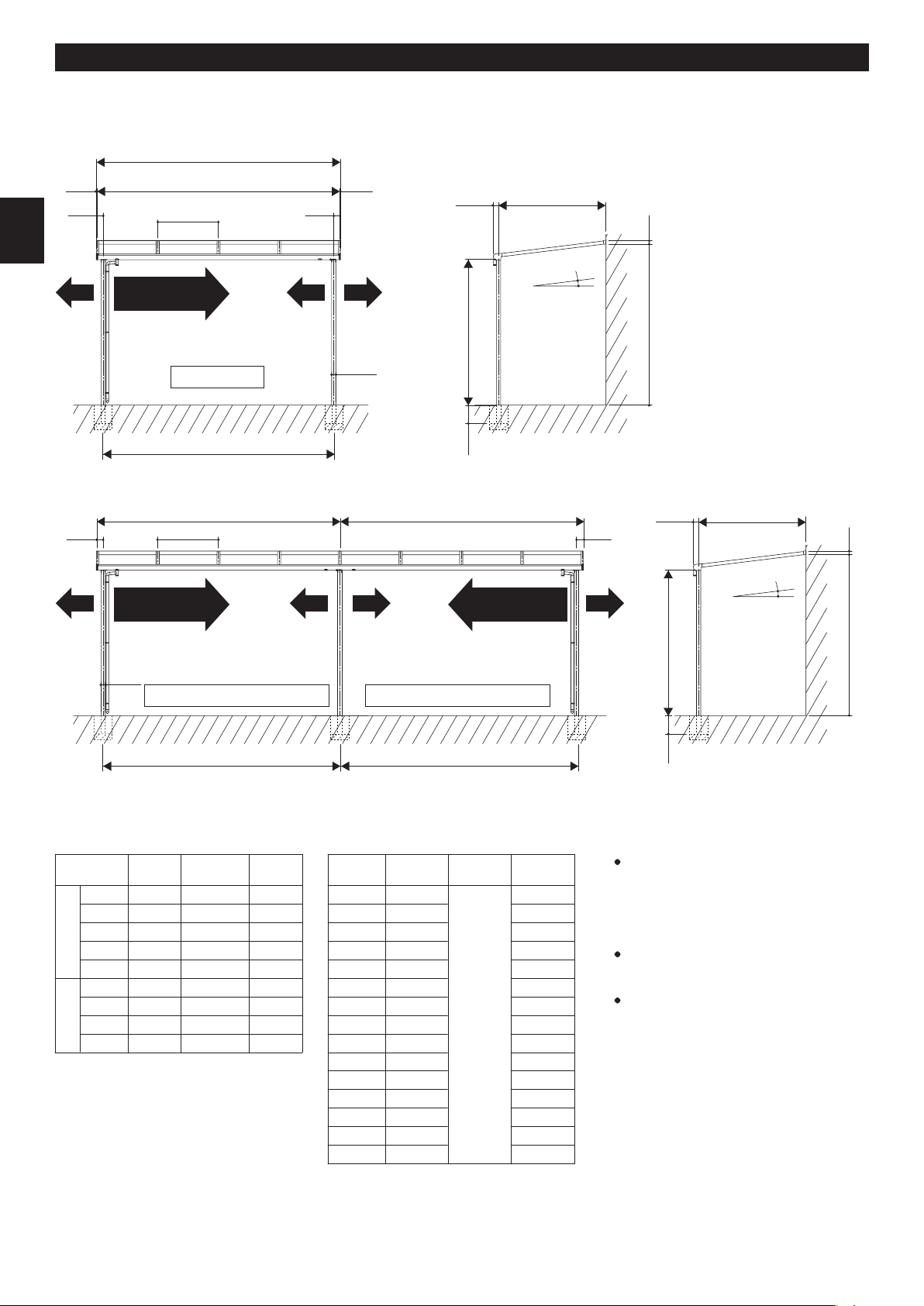

AssemblingmanualTerraceroofTR/TF-series600typeStandardinstallation

□Do not change or remodel it for another purpose except terrace roof.

□This product is for general areas. It has a snow accumulation strength of600N/m2(61.2kg/m2), which corresponds to 20cm of

fresh snowfall (specific weight 0.3). Do not install in heavy snow area.

□This product can be installed on the ground floor level. Please do not install on more than two -story.

□Do not install it in the place where snow slides down from the building roof directly or strong wind blow up this terrace roof.

□Standard installation of this product is installing on wooden body. When installing on the reinforced concrete structure or steel

structure except wooden house, please install by using optional parts and screws.

□Please check the house construction drawing and wall thickness before installation so that rear frame install firmly in the right

position of the house structural reinforcing materials (reinforced post, crossbeam, etc.). Do not install on the mortar part by

using plug anchors etc.

□Position the posts not to affect underground objects (water supply, drain pipes, etc.).

□When moving the posts, please follow the company specifications.

□Install it so that the exhaust of hot-water supply, heating and/or the car do not hit directly to the products and do not retain

around products. There is a possibility that the surface abnormality occurs as the coating film stripping.

Precautions during construction

□Follow the instructions and be sure that all the specified screws and bolts for assembly are tightened securely. Please tighten

the screws not to lean against the installation face.

□Tighten the M8 bolts at approx. 13Nm (130kgfcm) tightening torque.

□Do not use anything other than the specified parts or optional parts.

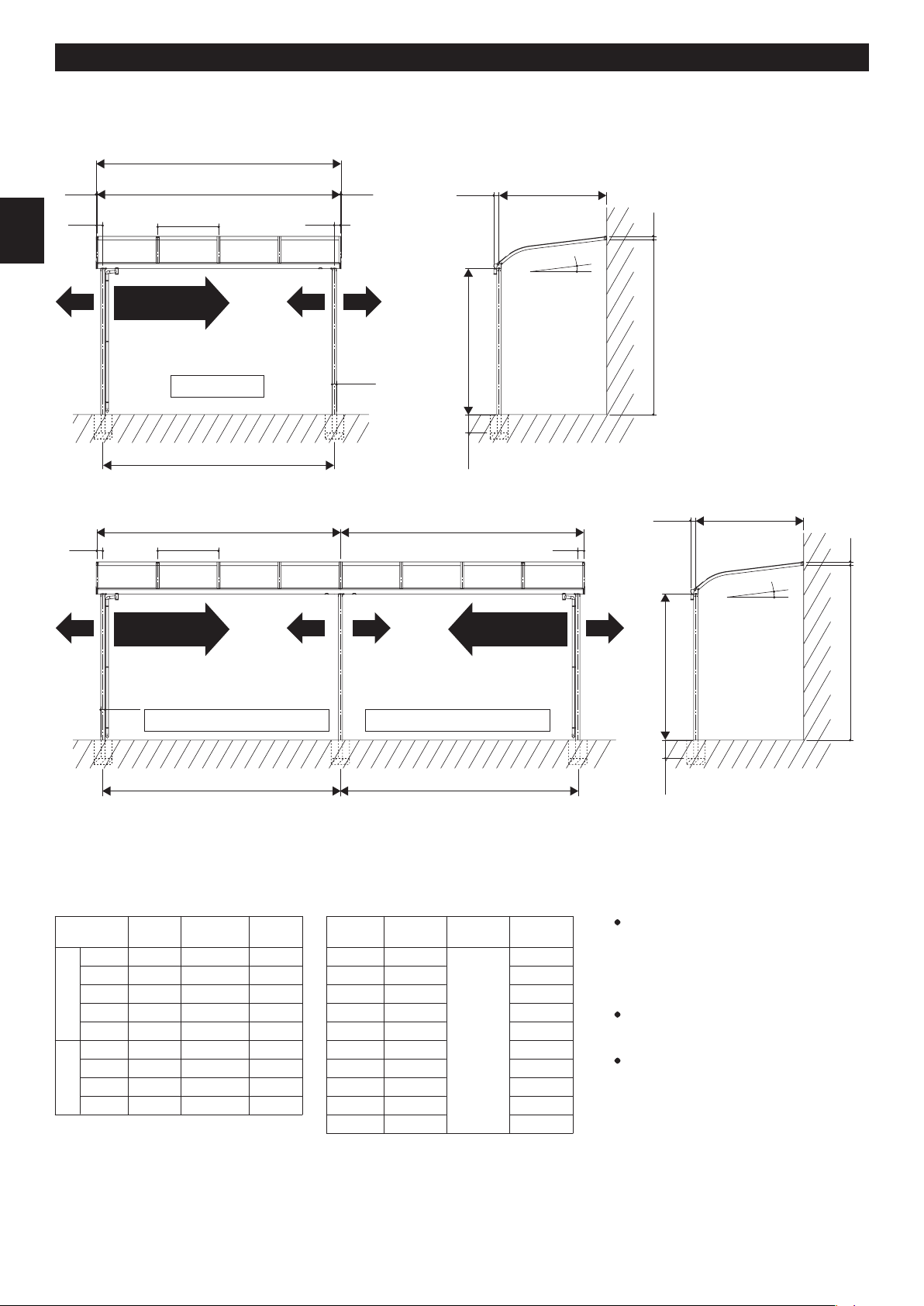

□The foundation should comply with or exceed dimension specifications.

□Please use the concrete and install the foundations.

□Allow sufficient curing time for the concrete (4 to 7 days) and do not place heavy objects on it or subject it to vibrations during

the curing period.

□Be sure to keep the note below to prevent aluminum materials corrode.

(1) Do not use sea sand for the foundation since it contains

salt and may cause corrosion. Do not use a cement

enhancer, water-reducing agent or cryoprotectant. They

may cause the posts to corrode.

(3) Be sure to provide gravel for the foundation to allow drain-

age, insert water drainage holes (φ5) at the base of the

posts and foundation. Failure to do so may lead to water

accumulation inside the posts and damage them if the

water freezes and expands inside.

(2) Immediately wipe off any mortar or stains from the surface

of aluminum parts since they may cause corrosion.

Thank you very much for choosing our company's products.

Please be sure to thoroughly read these instructions for assembly in order to properly and smoothly assemble or attach this pr oduct.

The precautions provided herein contain important information to ensure product performance, function, strength and safety.

Please be sure to follow them during construction.

Construction shall be implemented by professionals. Problems may occur if the product is installed by someone without the

proper knowledge.

Please be sure to return this manual to the owner after construction.

Notice

sea

sand

cement

enhancer water-

reducingcryopro

tectant

water

drainage

hole